Vertical shaft working face cement-water glass double-liquid and chemical slurry double-circle curtain combined grouting method

A technology of chemical grout and working face, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as poor grouting effect, reduction of ineffective grouting amount, difficulty of grouting in fine sandstone aquifer, etc. The grouting effect is good, the grouting effect is good, and the grouting amount is not large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

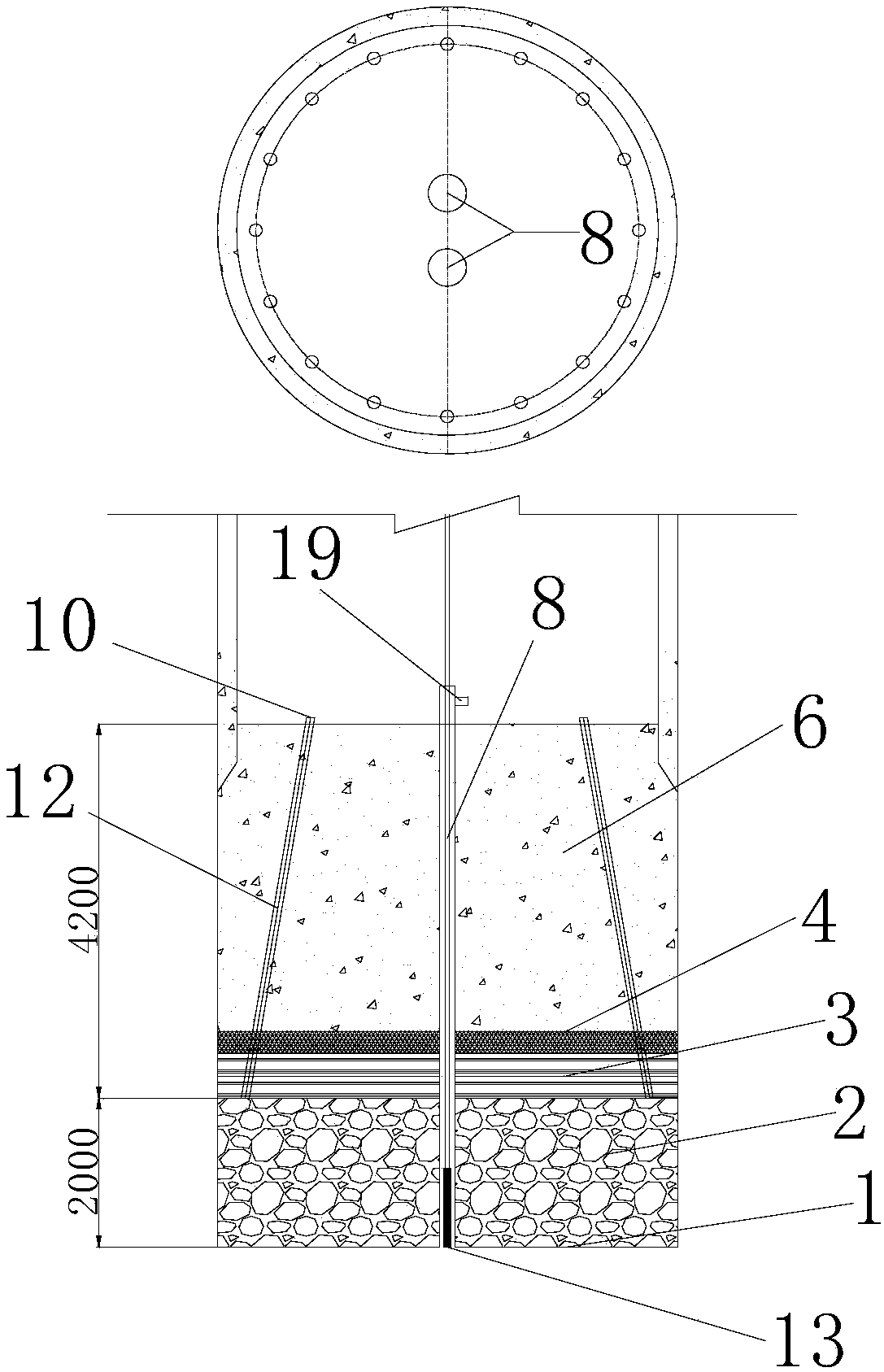

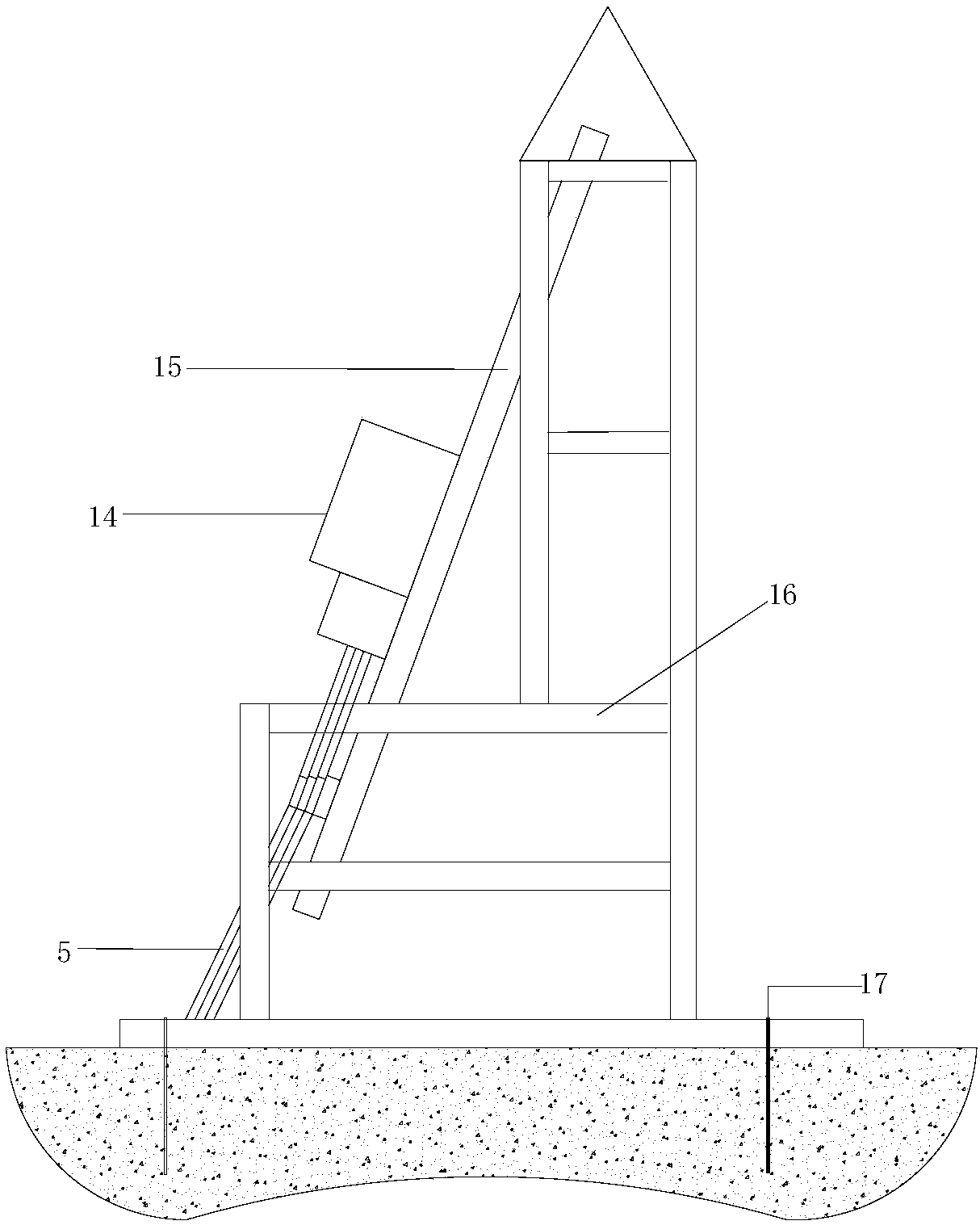

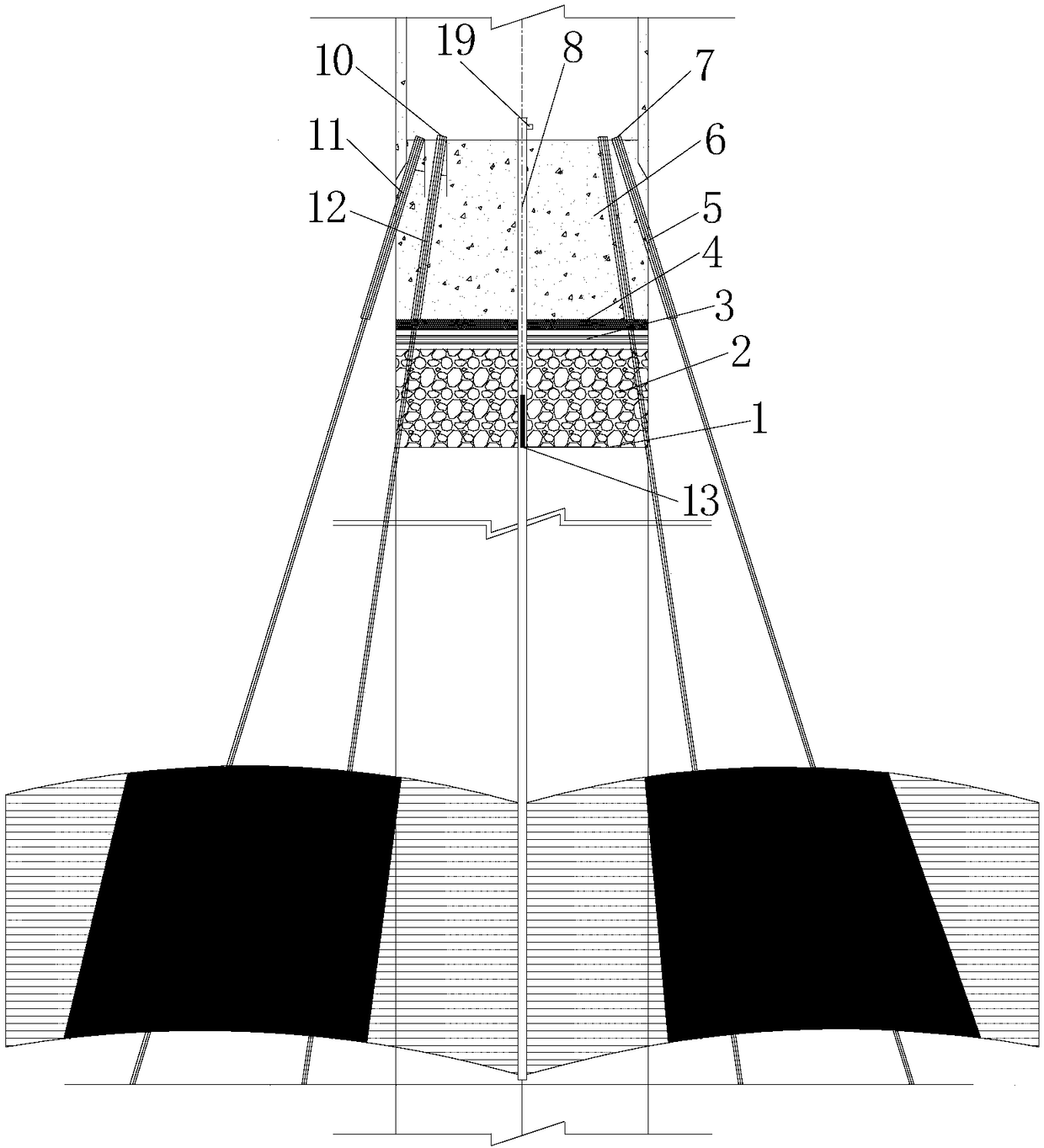

[0033] Below in conjunction with accompanying drawing and specific embodiment (the cement-water glass double liquid of the skip main shaft working face of a certain metal mine in the south and chemical grout double-circle curtain grouting are embodiment) to the present invention, a kind of vertical shaft working face cement-water glass Double-fluid and chemical grout double-circle curtain grouting method, further explanation of specific measures and implementation process.

[0034] Pre-grouting of the fine sandstone aquifer working face of the skip main shaft of a metal mine in the south. The net diameter of the skip main shaft is 6m, the support thickness is 300mm, and the total depth is 832m. In the well depth of 606.1 ~ 679.5m section is the fine sandstone aquifer.

[0035] (1) The bottom of the working face is cleared

[0036] Remove the gangue from the shaft working face 1 at the bottom of the well, clean up the floating gangue, and raise the steel mold to a position 5-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com