Corn kernel crush rate online detection method and device based on machine vision

A technology of machine vision and detection method, which is applied in the detection field, can solve the problems such as the difficult rate of corn kernel breakage, and achieve the effects of fast detection speed, good robustness and stability, and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical problems to be solved by the present invention, technical solutions and advantages clearer, the following will describe in detail in conjunction with the relevant drawings.

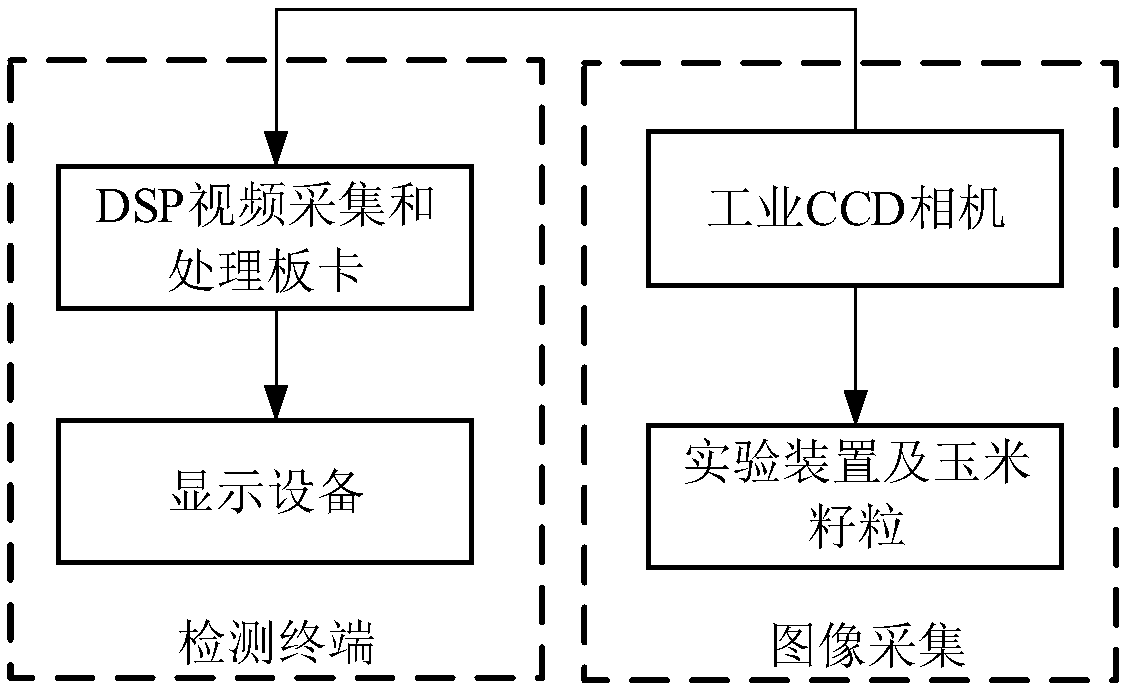

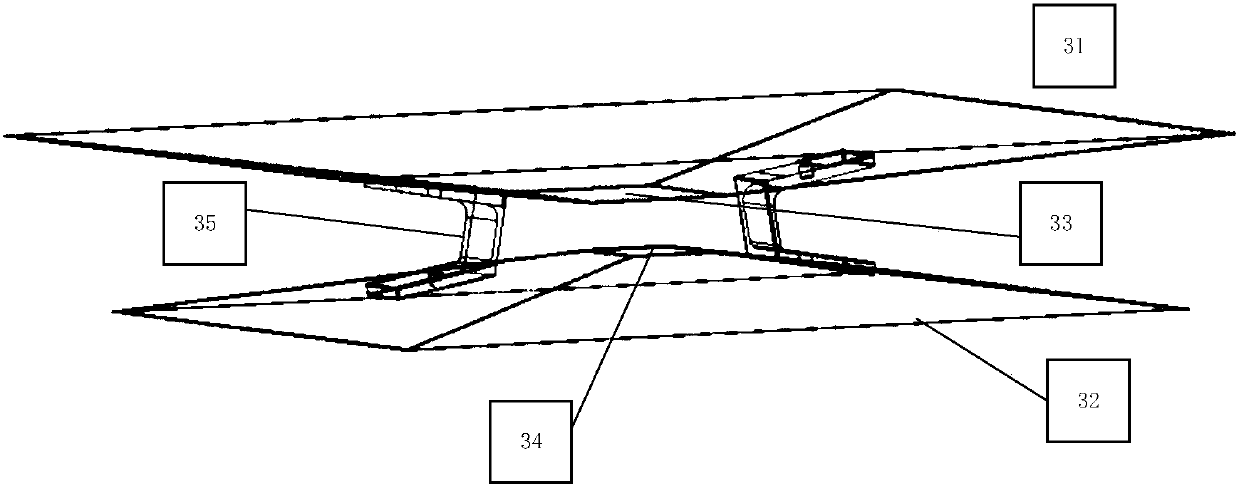

[0052] The present invention aims at the deficiencies in the detection of the broken rate of corn grains in my country's corn combined harvesting machinery, and proposes an online detection method and detection device for the broken rate of corn grains based on machine vision, combined with machine vision technology, image processing technology, pattern recognition technology, Related technologies such as CAN bus technology are used to distinguish intact corn kernels from broken corn kernels, and realize dynamic transmission of relevant data. A machine vision-based on-line detection device for the breakage rate of corn kernels of the present invention is installed in a grain box of a harvester.

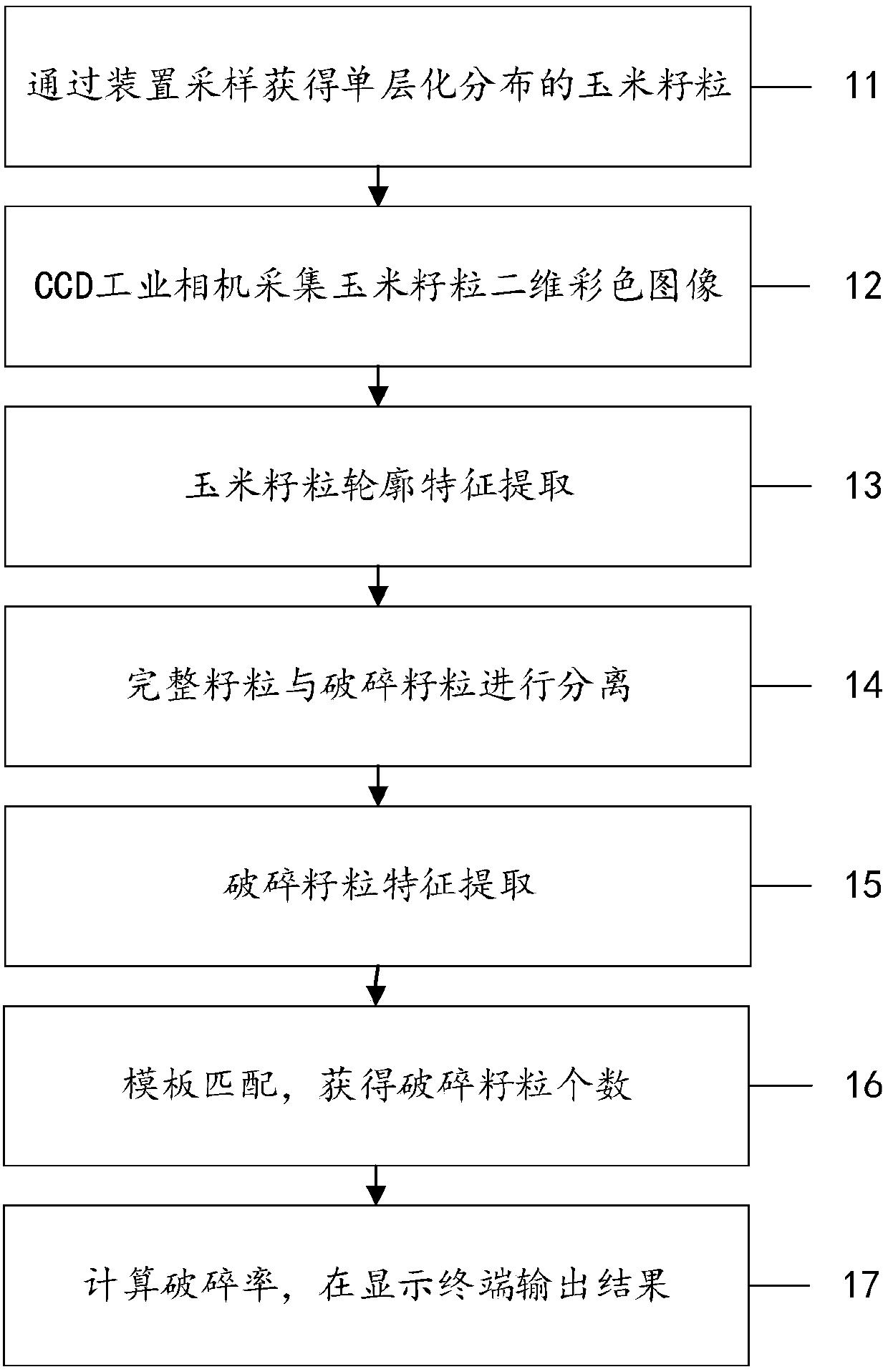

[0053] Such as figure 1 Shown, the present invention is based on the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com