Comparative test block for ultrasonic testing of structure uniformity of composite materials and preparation method thereof

A composite material and comparison test block technology, which is applied in the preparation of test samples, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, etc. The effect of judgment and omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

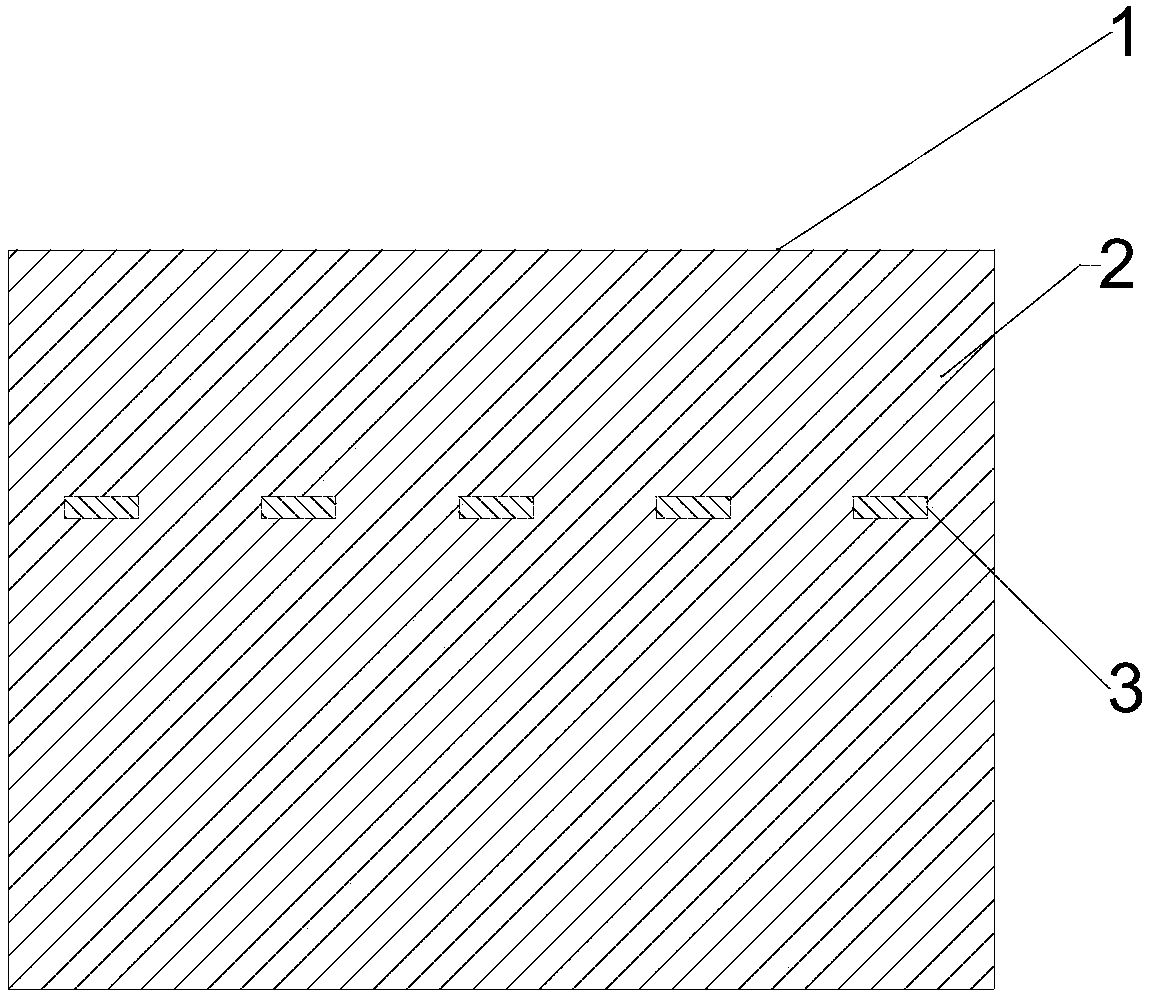

Embodiment 1

[0033] The comparative test block used for ultrasonic detection of the microstructure uniformity of SiC particle reinforced aluminum matrix composites with a volume fraction of 15% is a cuboid test block with a length, width and height of 200mm, 100mm and 300mm respectively, and four diameters in the test block are The depth of the 5mm cylinder area from the upper surface of the test block is 200mm, and the height is 2-3mm. The roughness of the upper and lower surfaces of the test block reaches Ra1.6; The volume fractions of SiC particles in the regions are 25%, 35%, 45%, and 55%, respectively.

[0034] The preparation method of described contrast test piece, comprises the following steps:

[0035] (1) Calculate, weigh, and evenly mix SiC particles and Al alloy powder to obtain a mixed powder with a volume fraction of 15% SiC particles and 85% Al alloy powder, and put it into a rubber sheath for compaction and flattening to obtain a cuboid-shaped composite material Body blank...

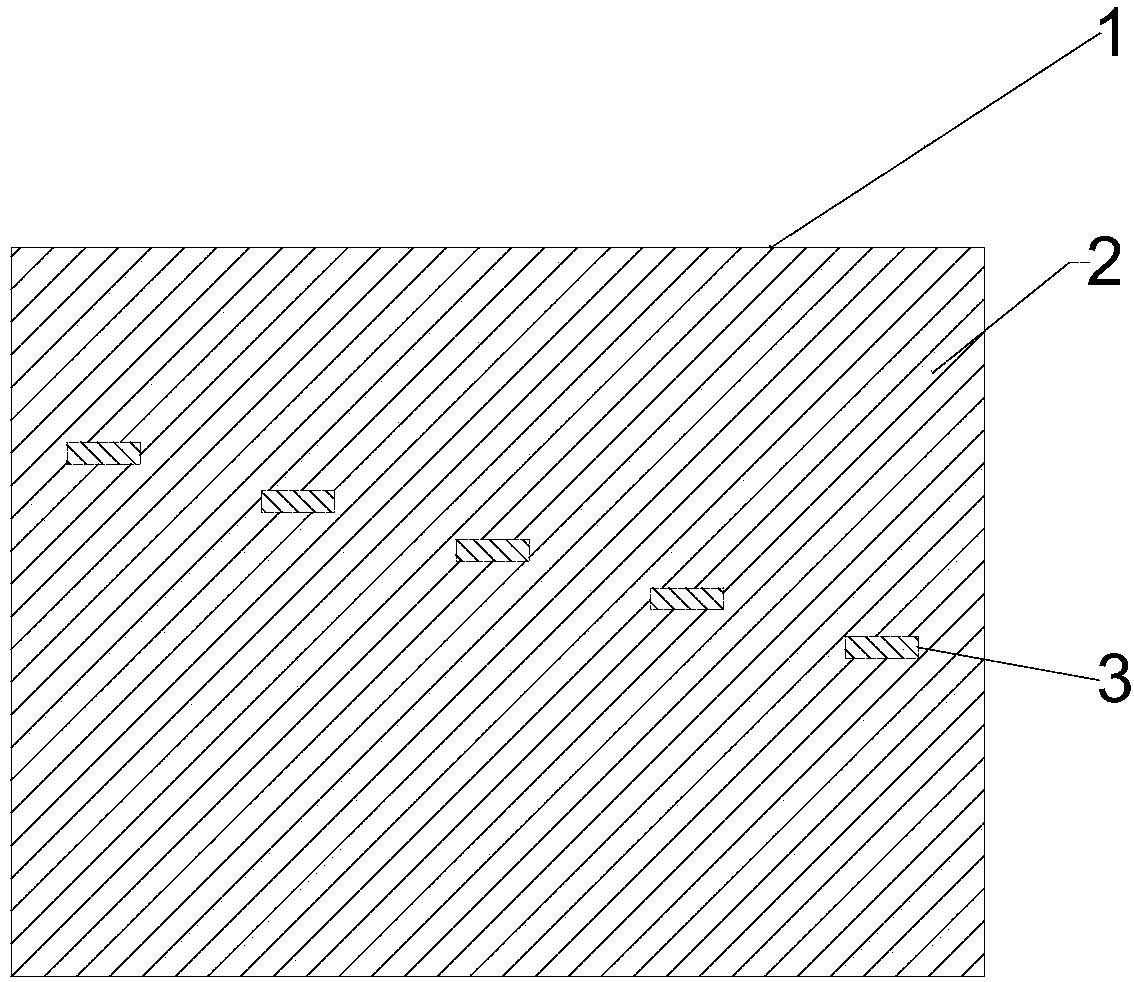

Embodiment 2

[0044] The comparative test block used for ultrasonic detection of the uniformity of the copper matrix composite material with a volume fraction of 60% WC particles is a cuboid test block with a length, width, and height of 100mm, 100mm, and 15mm, respectively. The four diameters in the test block are The depth of the 2mm cylinder area from the upper surface of the test block is 10mm, and the height is 1-2mm. The roughness of the upper and lower surfaces of the test block reaches Ra1.6; the test block body is 60% WC particle reinforced copper matrix composite material, 4 cylinders The volume fractions of WC particles in the regions were 20%, 30%, 40%, and 50%, respectively.

[0045] The preparation method of described contrast test piece, comprises the following steps:

[0046] (1) Calculate, weigh, and evenly mix WC particles and Cu alloy powder to obtain a mixed powder with a volume fraction of 60% WC particles and 40% Cu alloy powder, and put it into a rubber sheath to tamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindrical diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com