Postoperative repairing mask and preparation method thereof

A mask and konjac grape technology, applied in the field of skin care products, can solve problems such as skin burden, inflammation, skin damage, and adverse effects, and achieve the effects of repairing skin problems, repairing damaged skin, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

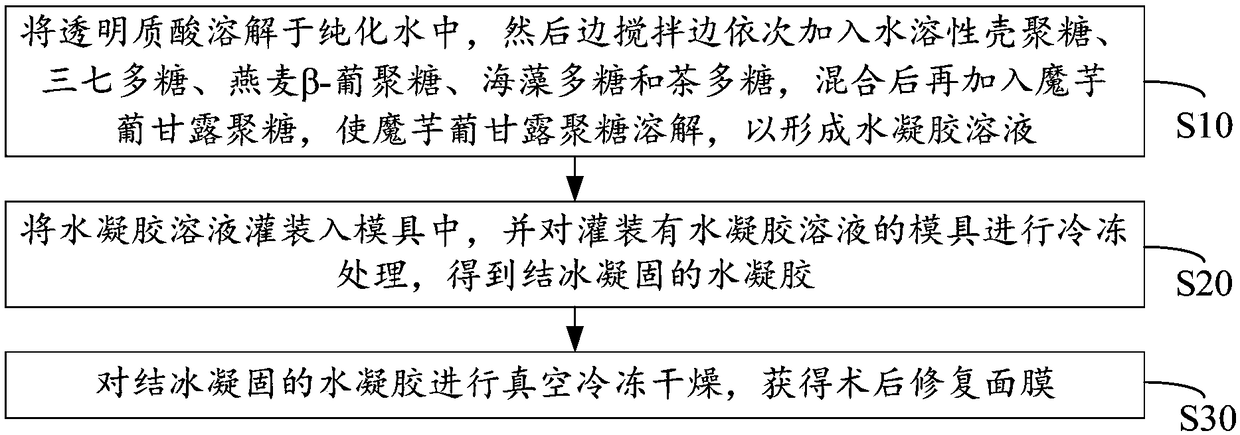

Method used

Image

Examples

preparation example Construction

[0023] The present invention proposes a postoperative repair facial mask and a preparation method thereof, wherein, in one embodiment of the postoperative repair facial mask provided by the present invention, the postoperative repair facial mask includes the following components by mass fraction: konjac glucomannan 12-24%, water-soluble chitosan 15-19%, notoginseng polysaccharide 15-23%, oat β-glucan 9-14%, seaweed polysaccharide 3-10%, tea polysaccharide 3-6% and transparent Hyaluronic acid 13-38%.

[0024] The postoperative repair facial mask provided by the present invention utilizes the excellent gelling properties of konjac glucomannan, combined with the functions of moisturizing, anti-inflammatory and swelling, promoting wound healing, and repairing damaged skin that various biological polysaccharides have, so as to achieve effective Repair skin problems after facial plastic surgery; and the post-operative repair mask prepared by preparing polysaccharide solution, gel in...

Embodiment 1

[0039] (1) Preparation of polysaccharide solution

[0040] Add 600g of hyaluronic acid into 10kg of purified water and stir to dissolve for 2 minutes, then add 300g of hydroxymethyl chitosan, 250g of notoginseng polysaccharide, 150g of oat β-glucan, 50g of seaweed polysaccharide and 50g of tea polysaccharide in turn while stirring, continue After stirring for 5 minutes until uniformly mixed, 200 g of konjac glucomannan (90% glucomannan content) was added, and stirred for 4 minutes until a hydrogel solution was formed.

[0041] (2) Forming and drying of postoperative repair mask

[0042] Inject the hydrogel solution prepared in step (1) into the KM245 mold through a filling machine, and then place the mold in a -36°C ultra-low temperature freezer for 3 hours to obtain a frozen and solidified hydrogel; Under certain conditions, put the frozen and solidified hydrogel at a low temperature of -36°C to sublimate the water in it directly into water vapor. The sublimation temperature...

Embodiment 2

[0044] (1) Preparation of polysaccharide solution

[0045] Add 300g of hyaluronic acid into 10kg of purified water and stir to dissolve for 3 minutes, then add 200g of carboxymethyl chitosan, 200g of low molecular weight chitosan, 500g of Panax notoginseng, 300g of oat beta-glucan, 150g of seaweed The polysaccharide and 100g tea polysaccharide were stirred for 8 minutes until uniformly mixed, then 500g konjac glucomannan (95% glucomannan content) was added, and stirred for 6 minutes until a hydrogel solution was formed.

[0046] (2) Forming and drying of postoperative repair mask

[0047] Inject the hydrogel solution prepared in step (1) into the KM245 mold through a filling machine, and then place the mold in a -50°C ultra-low temperature freezer for 10 hours to obtain a frozen and solidified hydrogel; Under certain conditions, the frozen and solidified hydrogel is sublimated into water vapor directly under the low temperature condition of -50°C. The sublimation temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com