Water-based fire extinguishing agent for extinguishing gasoline-type fire

A fire extinguishing agent and fire technology, applied in fire protection equipment and other directions, can solve the problems of large heat release, the ability of water mist to suppress gasoline to meet the fire extinguishing requirements, gasoline vapor ignition energy, low flash point and auto-ignition point, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A water-based fire extinguishing agent for extinguishing gasoline fires, the formula of which is:

[0028] Tween-20: 2%; (mass percentage)

[0029] KBr: 10%; (mass percentage)

[0030] Disodium EDTA: 0.2%; (mass percentage)

[0031] CO 2 Aqueous solution balance.

[0032] The preparation method of the fire extinguishing agent comprises the steps of: taking one or both of Tween-20, KBr or NaBr, and EDTA disodium according to the mass percentage; first dissolving EDTA disodium in water, stirring, and then After dissolving Tween-20 and KBr into water to form an aqueous solution, apply 0.7MPa CO on the solution 2 Gas, the fire extinguishing agent can be obtained after standing for more than 1 hour.

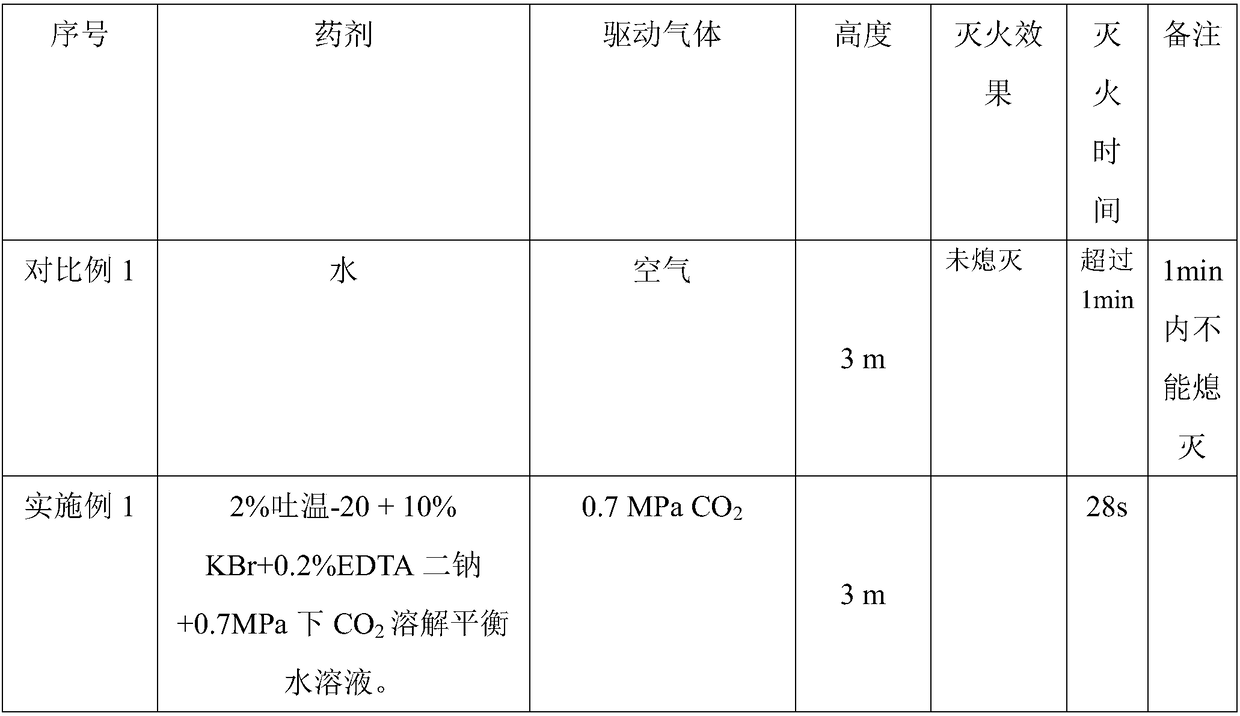

[0033] Using a solid cone water mist nozzle, under a pressure of 0.7MPa, D V0.99 =210.64μm, the flow rate is 1.31L / min. When the nozzle height is 3m, the diameter of the water mist coverage circle formed on the ground is about 80cm.

[0034] An oil pan with a diameter o...

Embodiment 2

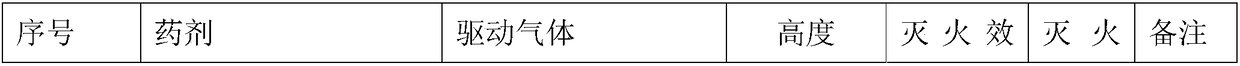

[0041] The conditions of injection, oil pan and gasoline in the experiment are the same as those in Example 1. In this case, each component in the formula was tested separately to prove that the composite fire extinguishing effect of the patented formula is far greater than that of a single component.

[0042]

[0043]

[0044] From this case, it can be found that in this patent formula, the fire extinguishing effect of the single component (disodium EDTA is only for removing calcium and magnesium ions in water) is not good, and the fire extinguishing effect of the aqueous solution of pure carbon dioxide is not good either. As shown in Example 1 (and Example 3 below), only combined formulas can exert a good fire extinguishing effect.

Embodiment 3

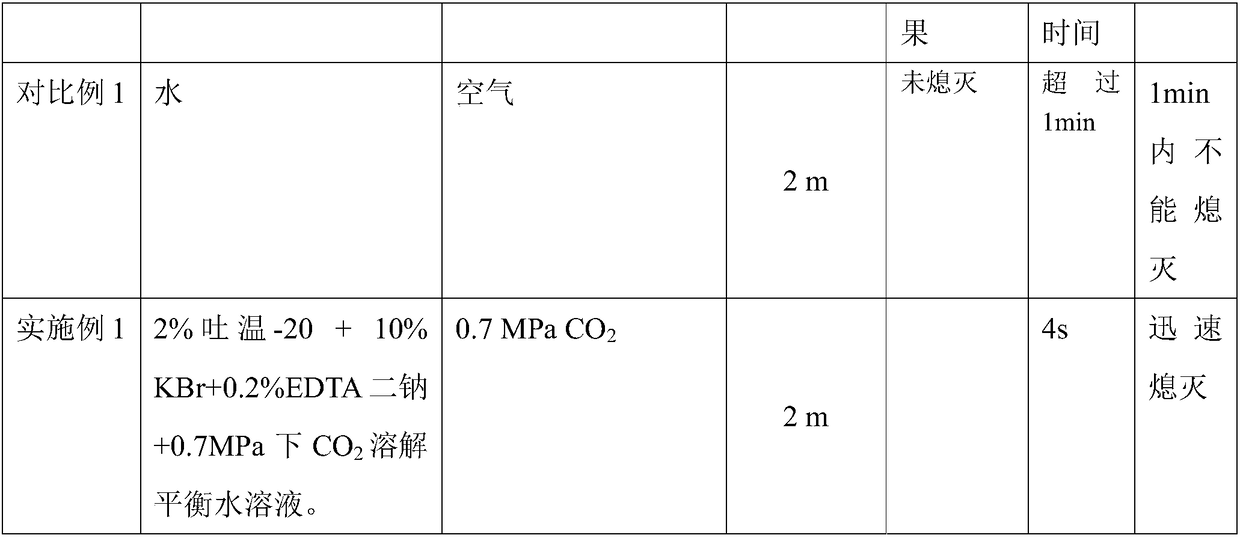

[0046] The conditions of injection, oil pan and gasoline in the experiment are the same as those in Example 1. This case is a fire extinguishing test for other concentrations and pressures of the formulation of the present invention.

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com