A kind of method that limestone replaces calcium carbide and is applied to lf refining

A technology of limestone and calcium carbide, which is applied in the field of metallurgy, can solve problems such as affecting the use effect, increasing production costs, and increasing the labor intensity of on-site operators, and achieves the effect of reducing consumption and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

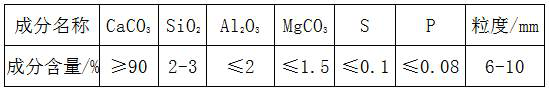

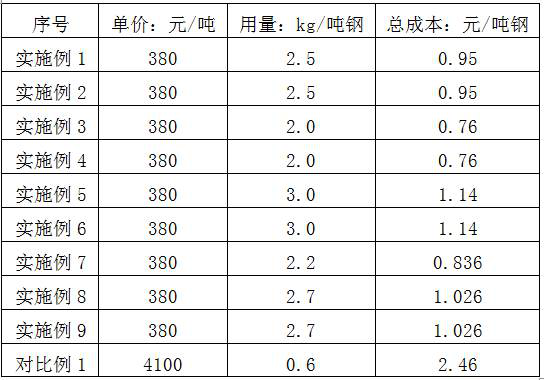

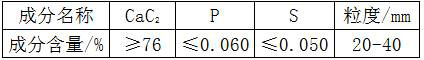

Embodiment 1

[0027] In this example, a method of applying limestone instead of calcium carbide to LF refining is used in the LF refining process of cold heading steel SWRCH22A. The weight of molten steel is 109t, and the temperature of molten steel entering the station is 1540°C. After the ladle enters the working position, connect and open the bottom Blow argon to adjust the argon flow rate to 200Nm³ / h, add lime 5.0kg / t steel, limestone 2.5kg / t steel, and add 0.7kg / t steel aluminum particles, 0kg / t steel calcium calcium powder, 0kg / t Iron silicon powder deoxidizer for steel, after stirring for 3 minutes, adjust the argon flow rate to 100Nm³ / h; then lower the electrode to heat, the initial heating time is 9 minutes, and the temperature of molten steel after heating is 1550°C. After the initial heating, take a refined slag sample for inspection, and the inspection results are as follows : CaO: 47.44%, SiO 2 : 16.25%, MgO: 10.41%, Al 2 o 3 : 19.81%, FeO: 1.2%, MnO: 1.4%; in the whole proce...

Embodiment 2

[0029] In this example, a method of applying limestone to LF refining instead of calcium carbide is used in the LF refining process of cold heading steel SWRCH22A. The weight of molten steel is 108t, and the temperature of molten steel entering the station is 1538°C. After the ladle enters the working position, connect and open the bottom Blow argon to adjust the argon flow rate to 250Nm³ / h, add lime 4.5kg / t steel, limestone 2.5kg / t steel, and add 0.6kg / t steel aluminum particles, 0kg / t steel calcium calcium powder, 0kg / t For ferrosilicon powder deoxidizer for steel, after stirring for 3 minutes, adjust the argon flow to 50Nm³ / h; then lower the electrode for heating, the initial heating time is 9 minutes, and the temperature of molten steel after heating is 1549°C. After the initial heating, take a refined slag sample for inspection, and the inspection results are as follows : CaO: 46.95%, SiO 2 : 16.48%, MgO: 10.52%, Al 2 o 3 : 19.23%, FeO: 1.3%, MnO: 1.6%; in the whole pro...

Embodiment 3

[0031] In this example, a method of applying limestone instead of calcium carbide to LF refining is used in the LF furnace refining process of rebar HRB400E. The weight of molten steel is 110t, and the temperature of molten steel entering the station is 1500°C. After the ladle enters the working position, connect and open the bottom blower Adjust the argon flow rate to 150Nm³ / h with argon gas, add lime 3.0kg / t steel, limestone 2.0kg / t steel, add 0kg / t steel aluminum particles, 0.5kg / t steel calcium calcium powder, 1.0kg / t For ferrosilicon powder deoxidizer for steel, adjust the argon flow to 80Nm³ / h after stirring for 3 minutes; then lower the electrode to heat, the initial heating time is 7 minutes, and the temperature of molten steel after heating is 1510°C. After the initial heating, take a refined slag sample for inspection, and the inspection results are as follows : CaO: 43.27%, SiO 2 : 28.51%, MgO: 12.7%, Al 2 o 3 : 6.52%, FeO: 1.43%, MnO: 2.42%; in the whole process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com