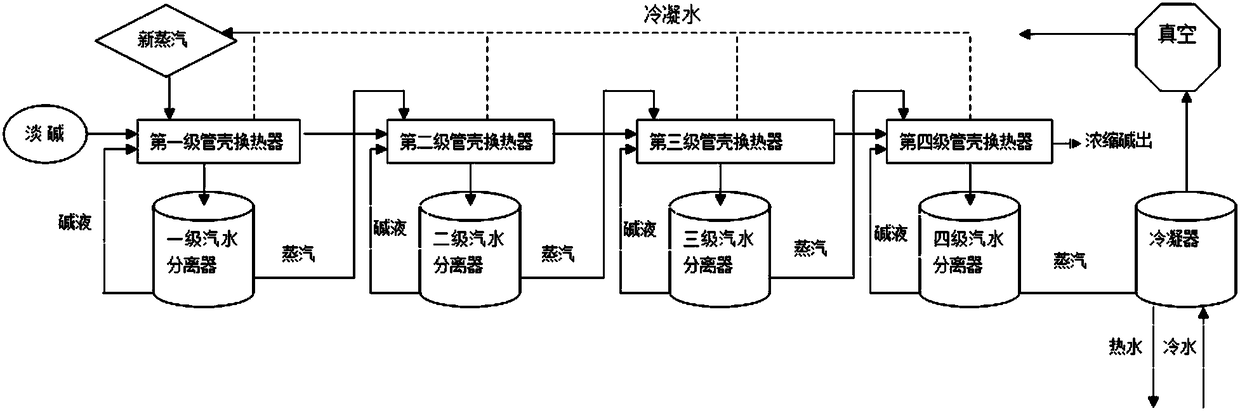

Multi-level light alkali evaporating unit and mercerized light alkali recovery system

An evaporation equipment and light alkali technology, which is applied in the printing and dyeing industry, can solve the problems of high cost and low evaporation efficiency of light alkali recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the present invention will be further described with an example below. This example is only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

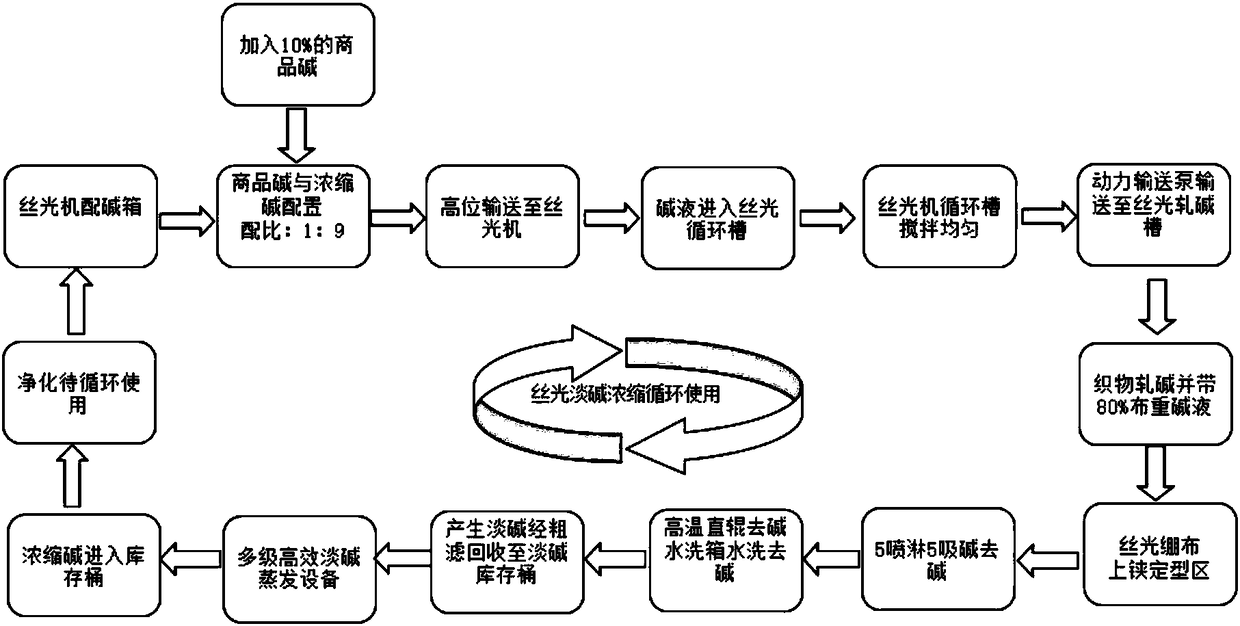

[0011] Dyeing and finishing mercerizing process is the key process to improve the dyeing performance of fabrics. After the fabric passes through high-concentration lye, the inside of the cotton fiber will expand and produce alkali cellulose, and the surface area of the fiber will increase. Under the action of tension, the fiber arrangement will be more orderly and the luster will be increased. The strength is improved. After the fabric is mercerized, the crystal area is reduced and the amorphous area is increased, and the adsorption capacity is greatly enhanced, thereby improving the adsorption capacity of the dye in the subsequent dyeing process, and the color yield is higher.

[0012] The use process of lye in mercerizing machine starts with alkali preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com