Environment-friendly coating for metal foil, as well as preparation method and application thereof

An environmentally friendly coating and metal foil technology, applied in the field of coatings, can solve the problems of construction personnel's health injury and environmental damage, and achieve the effects of avoiding fire hazards, improving water resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

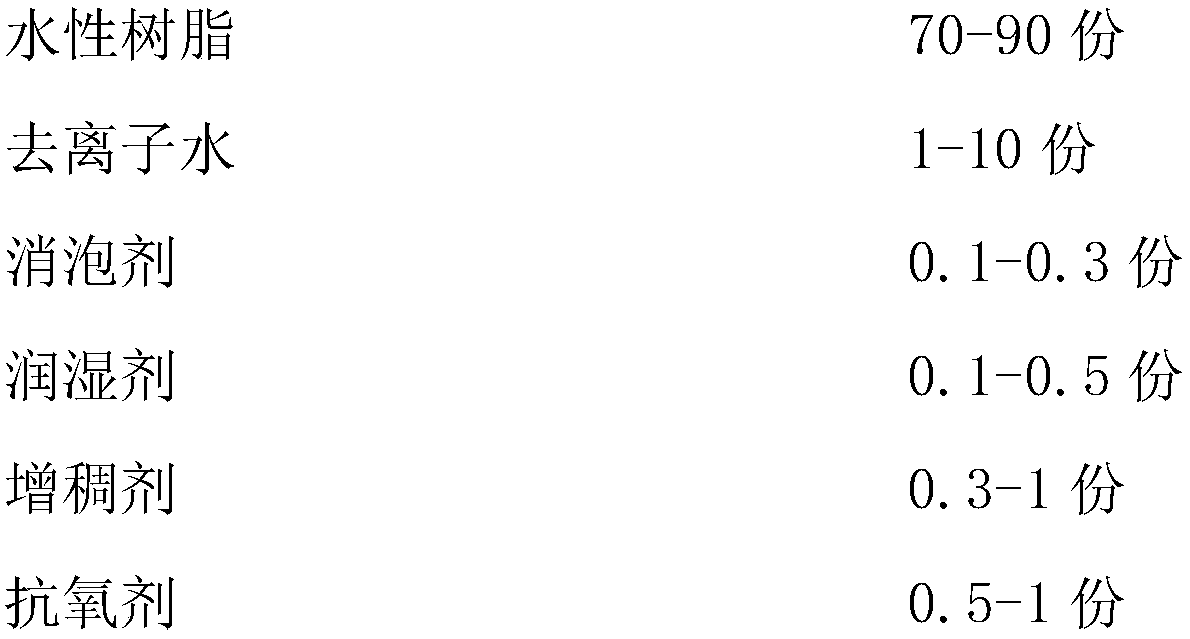

[0034] A kind of environmental protection paint that is used for metal foil, comprises the raw material of following weight part:

[0035]

[0036] Preferably, the water-based resin is polyurethane modified acrylic emulsion.

[0037] Preferably, the defoamer is TEGO810.

[0038] Preferably, the wetting agent is TEGO270.

[0039] Preferably, the thickener is RM-8W.

[0040] Preferably, the film-forming solvent is DPM.

[0041] Preferably, the antioxidant is BTA, and the fungicide is LXE.

[0042] A kind of its preparation method of the environment-friendly paint that is used for metal foil, comprises the steps:

[0043] (1) Put the water-based resin into the reaction tank, add wetting agent and defoamer while stirring, and disperse evenly to obtain mixed solution A, the stirring speed is 800 rpm, and the stirring time is 10 minutes;

[0044] (2) Add deionized water, film-forming aids, thickeners, antioxidants, bactericides and anti-fungal agents to the mixed solution A,...

Embodiment 2

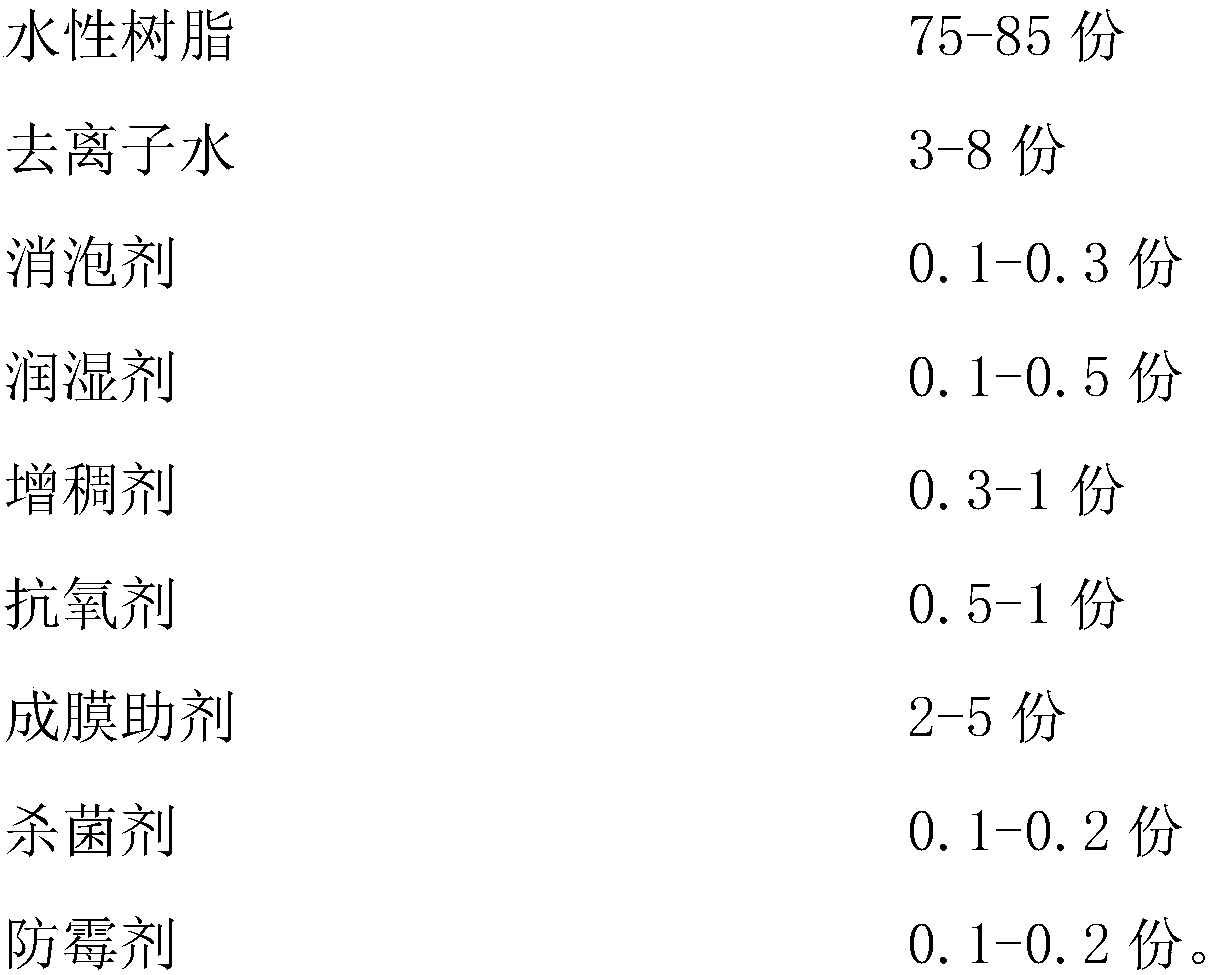

[0051] The difference between Embodiment 2 and Embodiment 1 is that an environmentally friendly coating for metal foils includes the following raw materials in parts by weight:

[0052]

[0053]

Embodiment 3

[0055] The difference between embodiment 3 and embodiment 1 is that an environmentally friendly coating for metal foil includes the following raw materials in parts by weight:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com