Coke drawing and drying method for industrial production of needle coke

A drying method, a technology of needle coke, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve the problems of instability, high thermal expansion coefficient, unstable operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

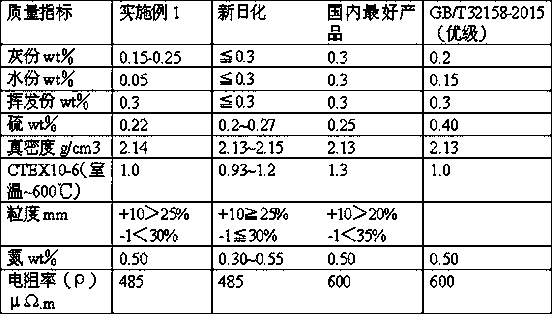

Examples

Embodiment Construction

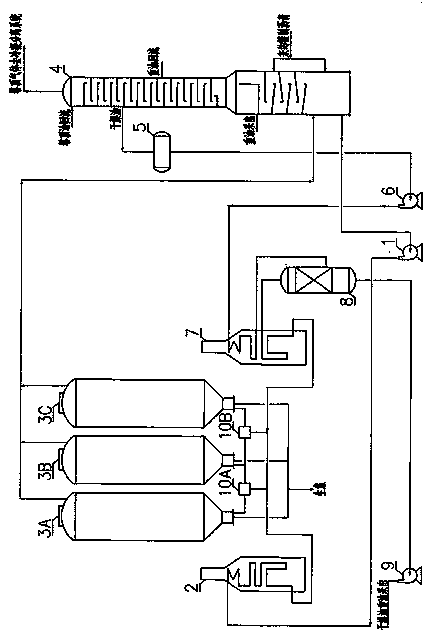

[0025] The coke pulling and drying method for the industrial production of needle coke in the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings.

[0026] The coking and drying method for the industrial production of needle coke according to the present invention, needle coke production includes three stages of raw material pretreatment, delayed coking and calcination, delayed coking is the key stage of needle coke production, coking raw materials are carbonized in the initial stage of coking tower The mesophase appears, and during further heating and carbonization, mesophase spheres grow, merge and form an optically anisotropic fibrous structure. After the coking raw materials are determined, it is very necessary to heat and carbonize the heat treatment conditions. During the heat treatment process, choosing a suitable atmosphere will affect the quantity and quality of mesophase small spheres, inhibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com