Novel production process of coal-based chemical

A chemical and new process technology, applied in organic chemistry, hydrotreating process, hydrogenation to hydrocarbons, etc., can solve problems such as difficulty in improving the selectivity of a single product, incomplete utilization of coal tar, coking of furnace tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

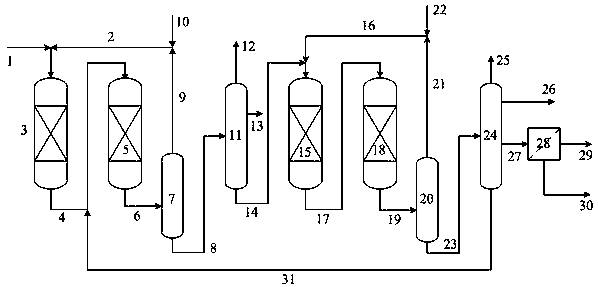

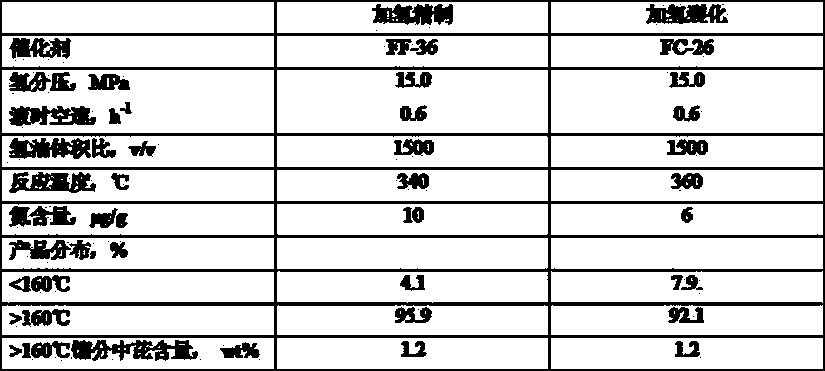

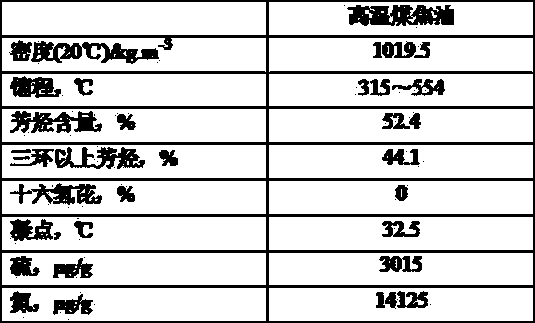

[0047] Such as figure 1In the process shown, the catalyst in the supplementary refining reaction zone is not segmented, but only one catalyst A is used. Hexadecahydropyrene can be obtained, and the yield and purity are shown in Table 4.

Embodiment 2

[0049] The hydrofinishing and hydrocracking parts are the same as in Example 1, and only catalyst B is used in the supplementary refining reaction zone. Hexadecahydropyrene can also be obtained, and the yield and purity are shown in Table 4.

Embodiment 3

[0051] The hydrofining and hydrocracking sections are the same as in Example 1, and the supplementary refining reaction zone is divided into two supplementary refining sections, and the gradation scheme of catalyst A and catalyst B is adopted. At the same time, the process conditions are also matched. The product yield and purity are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com