Fiber-reinforced high-corrosion-resistance alloy and preparation method thereof

A high-corrosion-resistant, fiber-reinforced technology, applied in the field of preparation of high-corrosion-resistant alloys, can solve problems such as unsatisfactory strength and poor corrosion resistance, so as to improve long-term corrosion resistance, increase tensile strength, Enhanced long-term antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

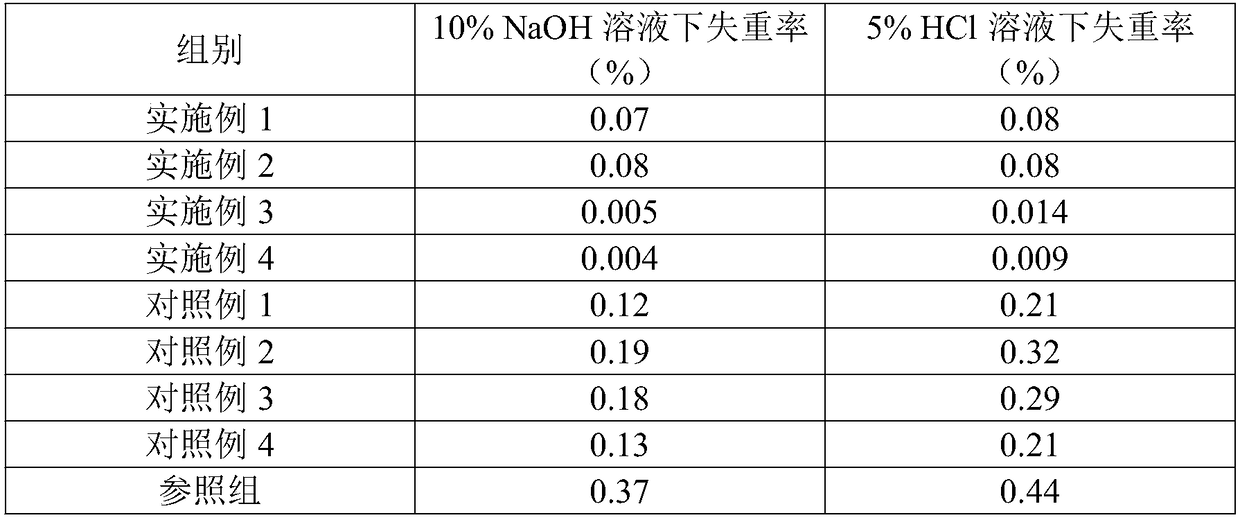

Examples

Embodiment 1

[0020] (1) preparing alloy fibers, the method is: according to the following weight percentages, prepare raw materials: 15% Fe, 30% C, 20% Ni, 2% W, 1% Sm, 1% V, 0.5% Mn, 0.03Ce, The balance is Al; the raw material is smelted at 1550-1580°C, and pulled by a water-cooled copper alloy runner to prepare alloy fibers, so that the diameter of the alloy fibers is 50-70 μm;

[0021] (2) placing the obtained alloy fiber in a steel mold, controlling the temperature of the steel mold to be 600-650° C., and controlling the alloy fiber to account for 35% of the cavity volume of the mold;

[0022] (3) Refining magnesium alloy liquid, the composition of magnesium alloy is calculated by weight: Y: 1%, Sn: 0.2%, Mg: 98.78%, total amount of impurities: 0.03%, wherein Fe: 0.001%, Cu: 0.001%, Si: 0.004%; the temperature of the magnesium alloy liquid is kept at 750°C;

[0023] (4) Control the vacuum in the steel mold to be -20KPa, inject the magnesium alloy liquid of step (3) into the result of ...

Embodiment 2

[0025] Except that the composition of the alloy raw material in step (1) is: 30% Fe, 20% C, 30% Ni, 2% W, 1% Sm, 1% V, 0.5% Mn, 0.03Ce, and the balance is Al , and the rest are consistent with Example 1.

Embodiment 3

[0027] In addition to the composition of the alloy raw material in step (1): 18.7% Fe, 21.3% C, 20% Ni, 2% W, 1% Sm, 1% V, 0.5% Mn, 0.03Ce, and the balance is Al , and the rest are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com