Magnesium alloy material with ca-p coating on surface carrying metal ions and its preparation method and application

A technology of metal ions and magnesium alloys, applied in metal material coating technology, coatings, pharmaceutical formulations, etc., can solve the problems of biocompatibility and antibacterial performance that need to be further improved, so as to improve physiological corrosion performance, accelerate deposition, and prevent Effects requiring special equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

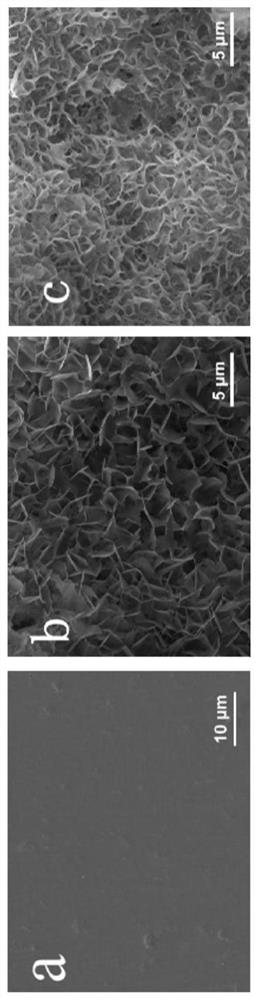

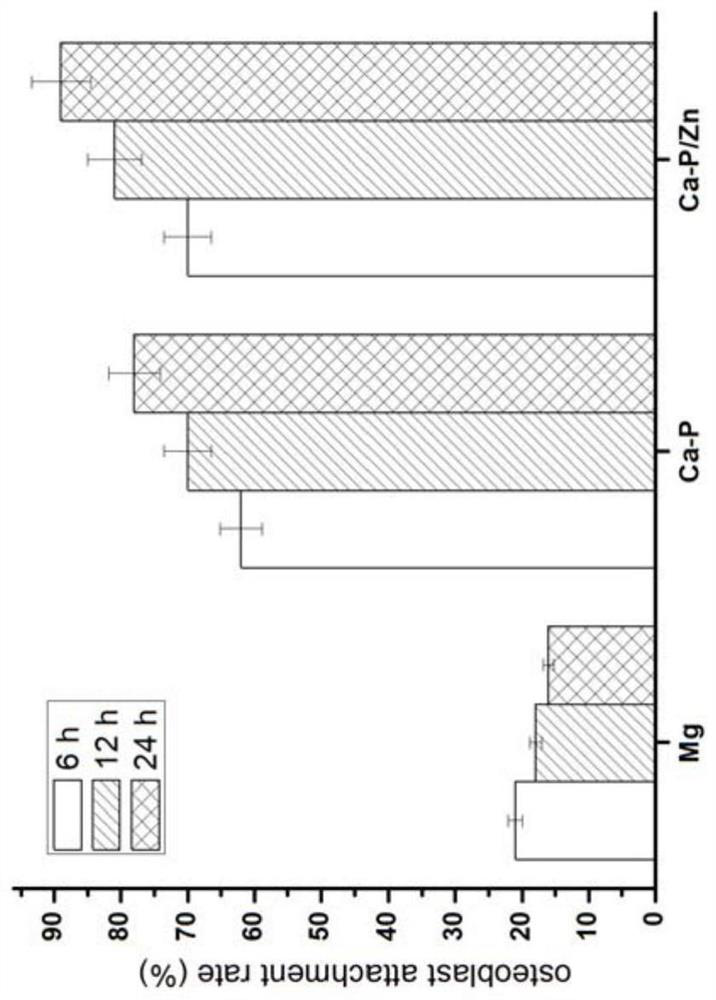

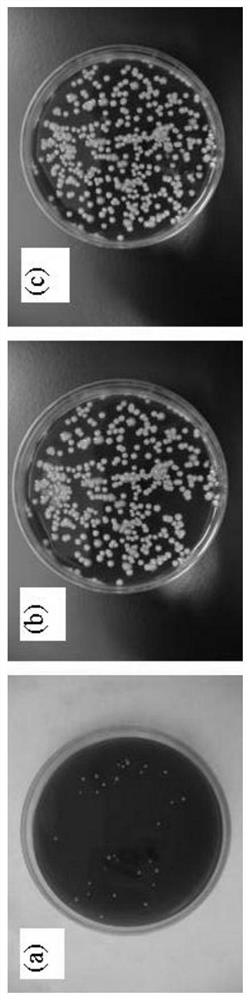

[0032] Embodiment 1 surface carries Zn 2+ Preparation of Ca-P Coated Magnesium Alloy Materials

[0033] 1) Chemical treatment of magnesium alloy surface

[0034] The polished magnesium alloy samples were immersed in NaOH solution and Na 3 PO 4 12H 2The mixed solution of O solution was treated for 2 hours, the treatment temperature was 80°C, the concentration of NaOH solution in the mixed solution was 20 / L, Na 3 PO 4 12H 2 The concentration of O solution is 5g / L.

[0035] 2) Preparation of magnesium alloy material with polydopamine coating fixed on the surface

[0036] Step 1) Submerge the chemically treated magnesium alloy material into a 0.1 mg / ml dopamine solution at pH 8.0, react at room temperature for 24 hours, then fully wash and dry, and repeat several times to obtain a magnesium alloy material with a polydopamine coating fixed on the surface.

[0037] 3) Preparation of magnesium alloy material with chitosan immobilized on the surface

[0038] The magnesium all...

Embodiment 2

[0043] Example 2 Surface-loaded Ag + Preparation of Ca-P Coated Magnesium Alloy Materials

[0044] 1) Chemical treatment of magnesium alloy surface

[0045] The polished magnesium alloy samples were immersed in NaOH solution and Na 3 PO 4 12H 2 The mixed solution of O solution was treated for 12 hours, the treatment temperature was 50°C, the concentration of NaOH solution in the mixed solution was 60g / L, Na 3 PO 4 12H 2 The concentration of O solution is 20g / L.

[0046] 2) Preparation of magnesium alloy material with polydopamine coating fixed on the surface

[0047] The magnesium alloy material was immersed in a 1 mg / ml dopamine solution with a pH of 8.0, reacted at room temperature for 12 hours, fully cleaned and dried, and repeated several times to obtain a magnesium alloy material with a polydopamine coating fixed on the surface.

[0048] 3) Preparation of magnesium alloy material with chitosan immobilized on the surface

[0049] The magnesium alloy material with ...

Embodiment 3

[0054] Example 3 surface loaded with Sr 2+ Preparation of Ca-P Coated Magnesium Alloy Materials

[0055] 1) Chemical treatment of magnesium alloy surface

[0056] The polished magnesium alloy samples were immersed in NaOH solution and Na 3 PO 4 12H 2 The mixed solution of O solution was treated for 7 hours, the treatment temperature was 65°C, the concentration of NaOH solution in the mixed solution was 40g / L, Na 3 PO 4 12H 2 The concentration of O solution is 12.5g / L.

[0057] 2) Preparation of magnesium alloy material with polydopamine coating fixed on the surface

[0058] The magnesium alloy material was immersed in a 0.5mg / ml dopamine solution with a pH of 8.0, reacted at room temperature for 18 hours, fully cleaned and dried, and repeated several times to obtain a magnesium alloy material with a polydopamine coating fixed on the surface.

[0059] 3) Preparation of magnesium alloy material with chitosan immobilized on the surface

[0060] The magnesium alloy materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com