Method for preventing C4F7N corrosion by metal surface treatment of electrical insulation equipment

A metal surface treatment and electrical insulation technology, which is applied in the direction of metal material coating process, solid diffusion coating, coating, etc., can solve the problems of performance degradation of metal parts of insulation equipment, drop of flashover voltage along the surface, and reduction of insulation performance. To achieve the effect of avoiding normal operation, preventing the generation of toxic gas and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

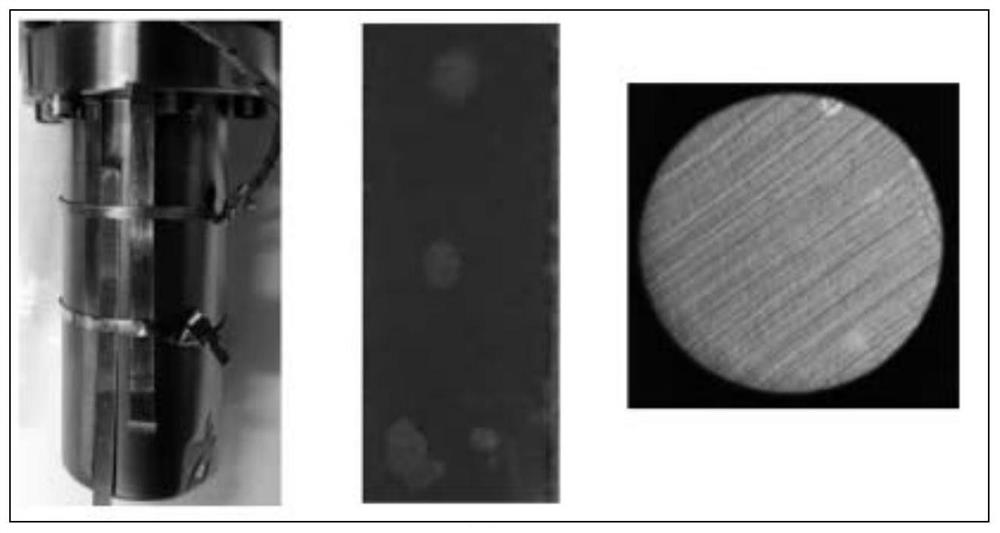

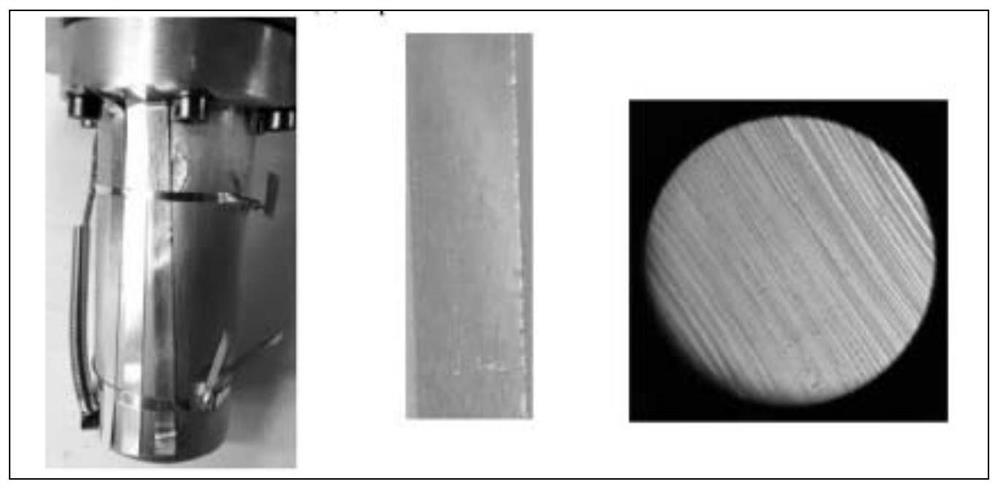

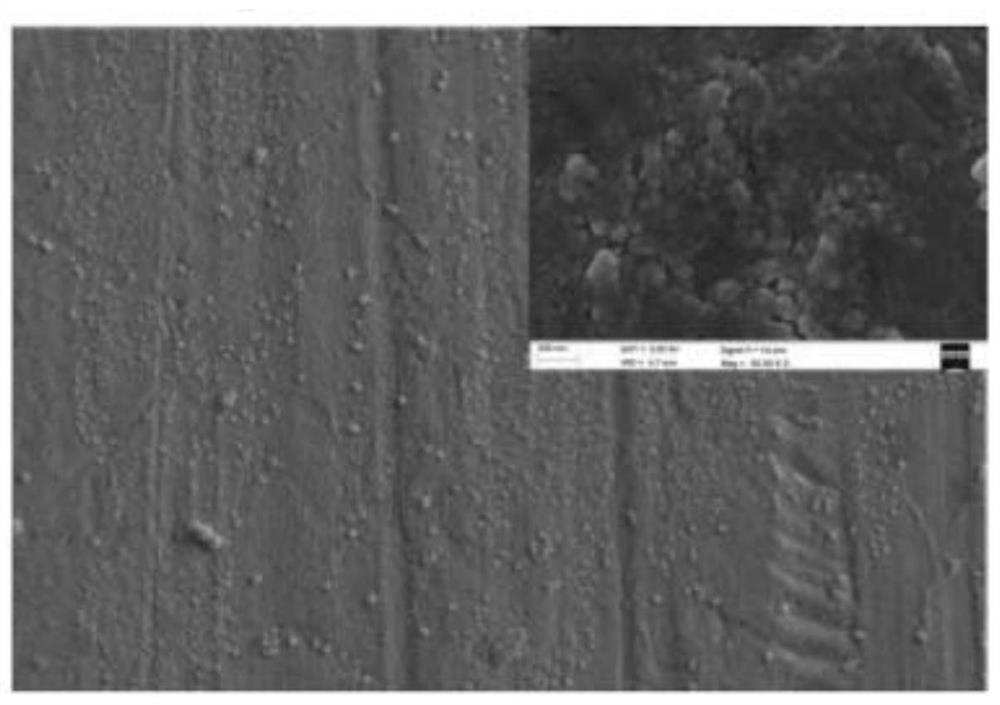

[0035] Surface treatment of a metal part (made of red copper) of electrical insulation equipment to prevent C 4 f 7 The method for N gas corrosion, the specific steps are as follows:

[0036] 1) Clean the copper parts: soak the copper parts in a cleaning agent (sodium nitrite 0.3wt%, sodium carbonate 0.5wt%, the balance is water) at 60°C, and use an ultrasonic cleaner (power 0.5W / cm 2 ) Clean the parts for 10 minutes, then rinse the metal parts with water at 80-90°C for 5 minutes, and place them in a dryer at 60°C for 2 hours to dry;

[0037] 2) Soak the cleaned parts in an activator at 90-100°C, the components and mass percentage of the activator are: 5wt% Na 2 B 4 o 7 , 1.5 wt% NH 4 Cl, the balance is water;

[0038] 3) Aluminum plating on the surface of metal parts by hot-dip aluminum plating: immerse the metal parts after surface activation in immersion plating solution at 550°C for 4 minutes. The composition and mass percentage of the immersion plating solution are:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com