Method for improving corrosion resistance of amorphous coating and application thereof

An amorphous coating, corrosion resistance technology, applied in the direction of coating, surface reaction electrolytic coating, metal material coating process, etc., can solve the problems of unevenness, weak bonding interface, weak passivation film, etc. Generate and homogenize, reduce weak points, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a treatment method for an amorphous coating and its corrosion resistance has been tested. The specific steps are as follows:

[0035] (1) Substrate treatment: use ultrasonic acetone to clean the substrate (carbon steel) to remove the oil on the surface, then use brown corundum with a particle size of 400 mesh to sandblast the substrate to remove the oxide skin on the surface of the substrate and increase the roughness;

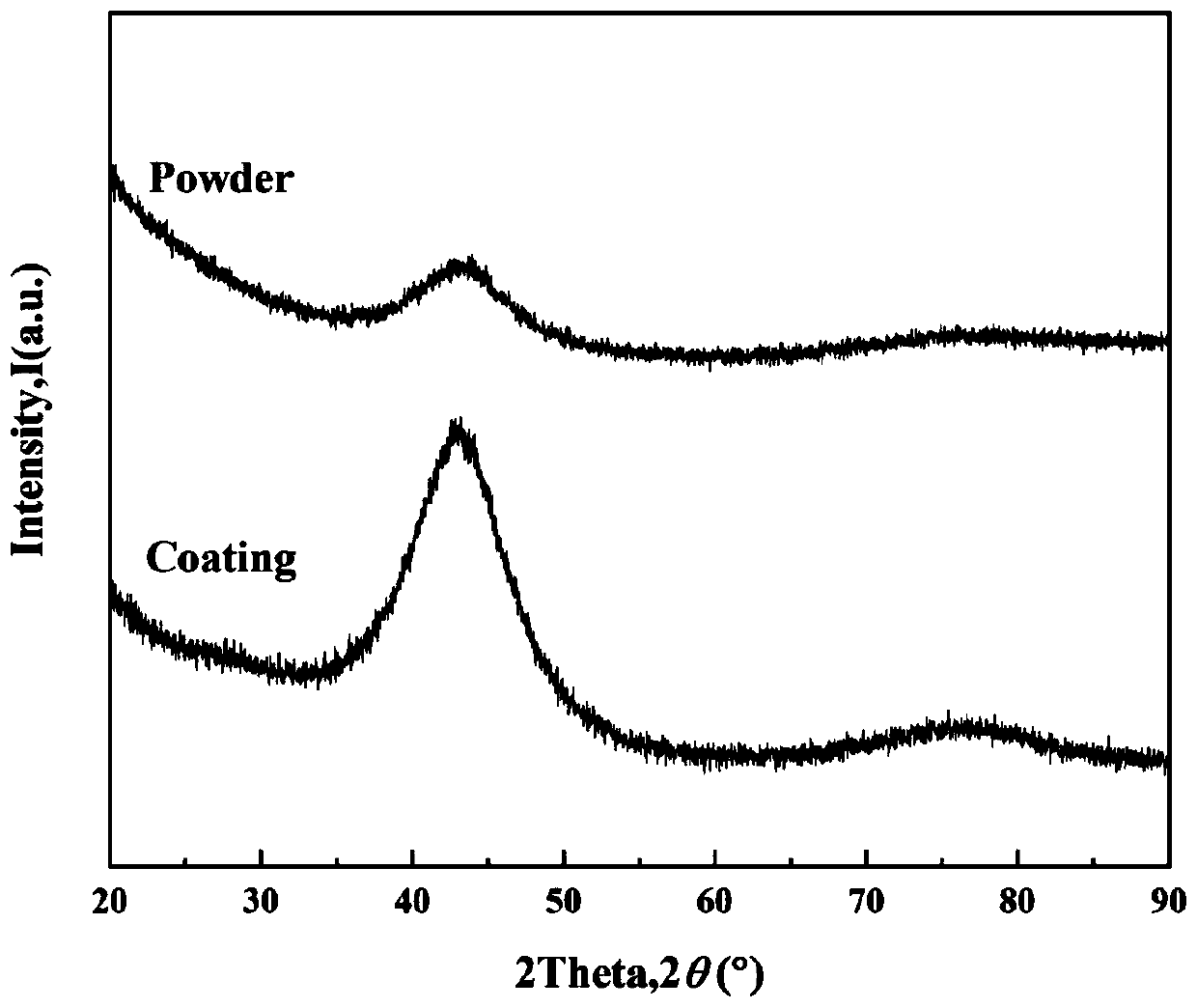

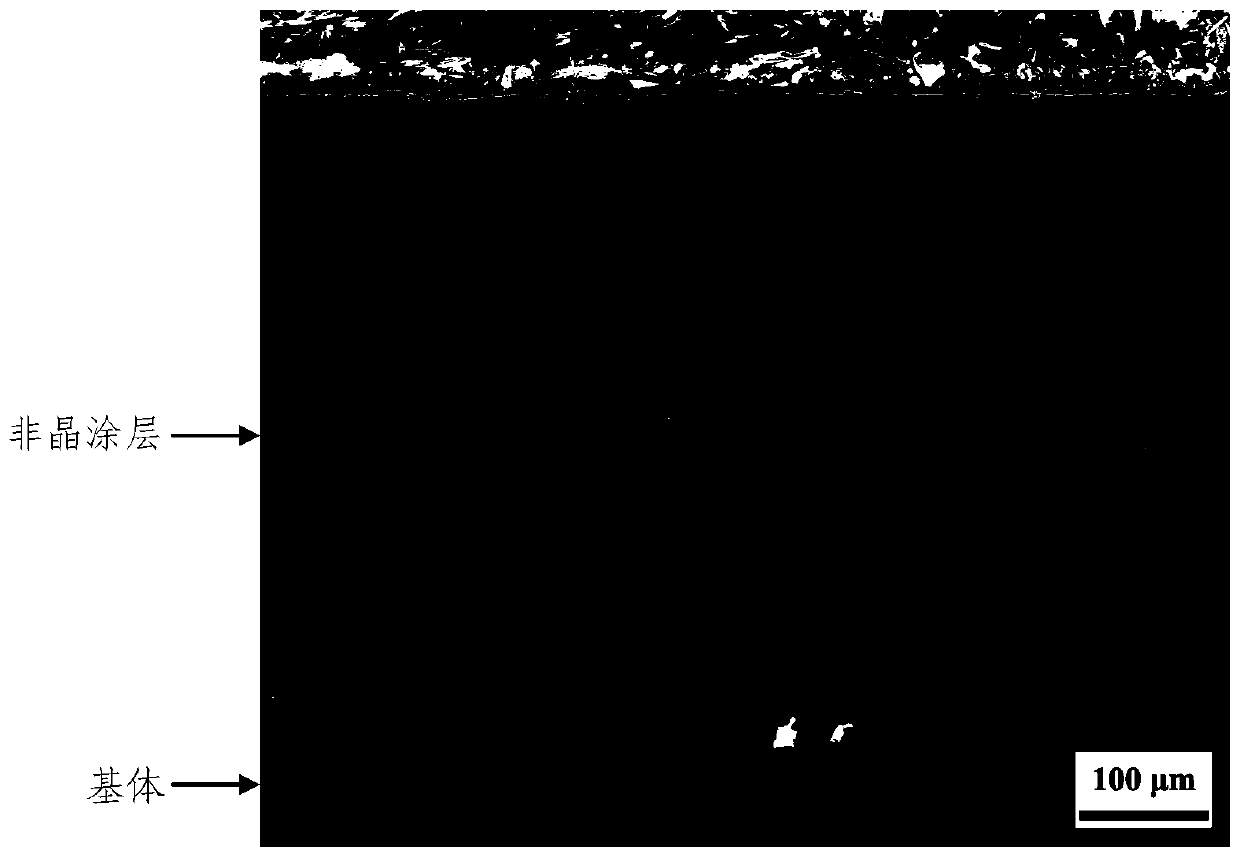

[0036] (2) Coating preparation: use amorphous alloy powder Fe prepared by gas atomization 48 Cr 15 Mo 14 C 15 B 6 Y 2 (25 ~ 45μm) as a spraying raw material. figure 1 is the SEM topography of the amorphous alloy powder, from figure 1 It can be seen that most of the powders are spherical, and the sphericity is high, only a few have satellite organization, which ensures the fluidity of the powder during the spraying process. The JP-5000 supersonic flame spraying equipment of Praxair-TAFA was used to prepare an amorphous coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com