Nozzle with laser scanning head for direct metal deposition

A laser scanner, direct technology, applied in the field of laser scanners, which can solve problems such as expensive and infeasible large parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

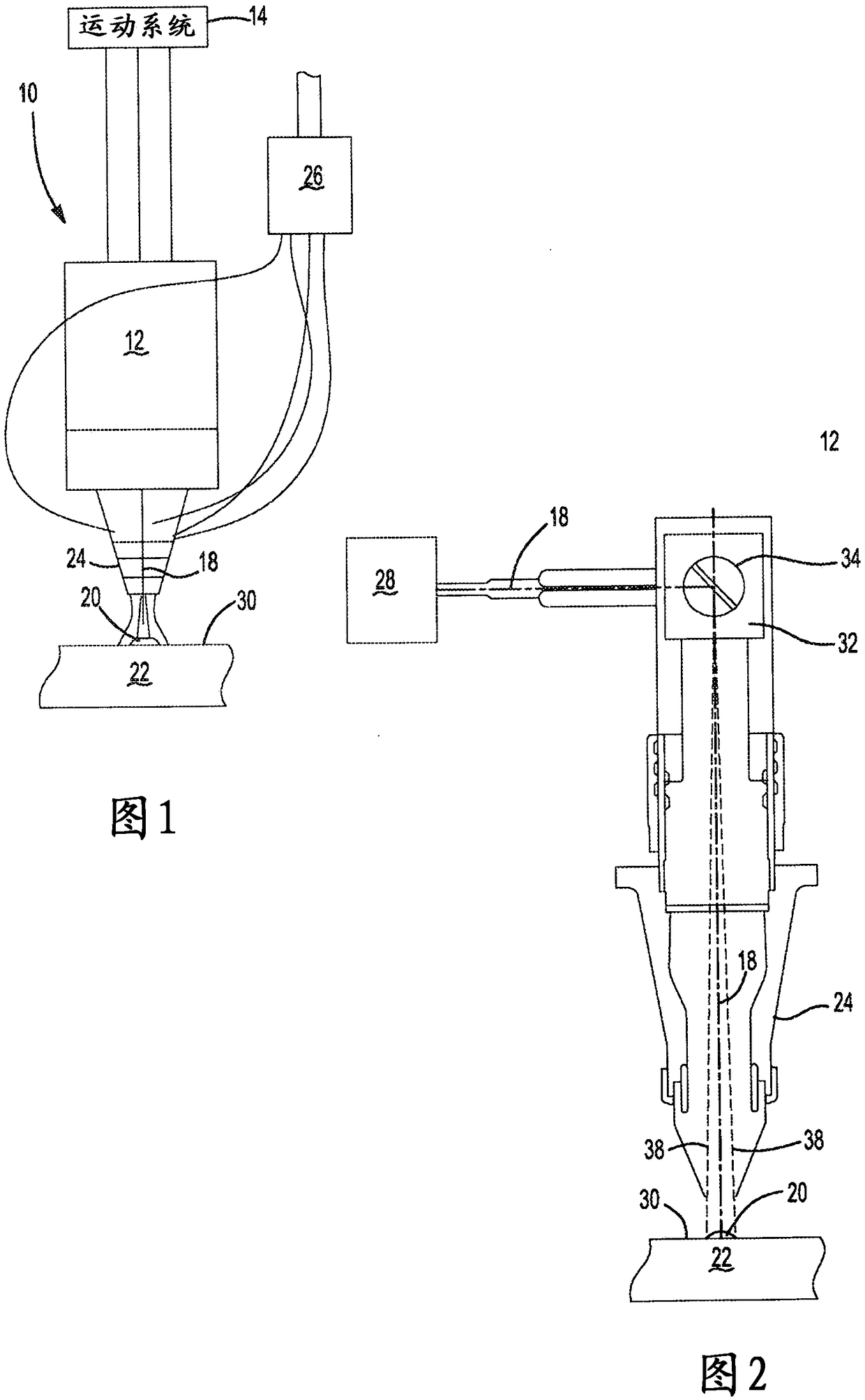

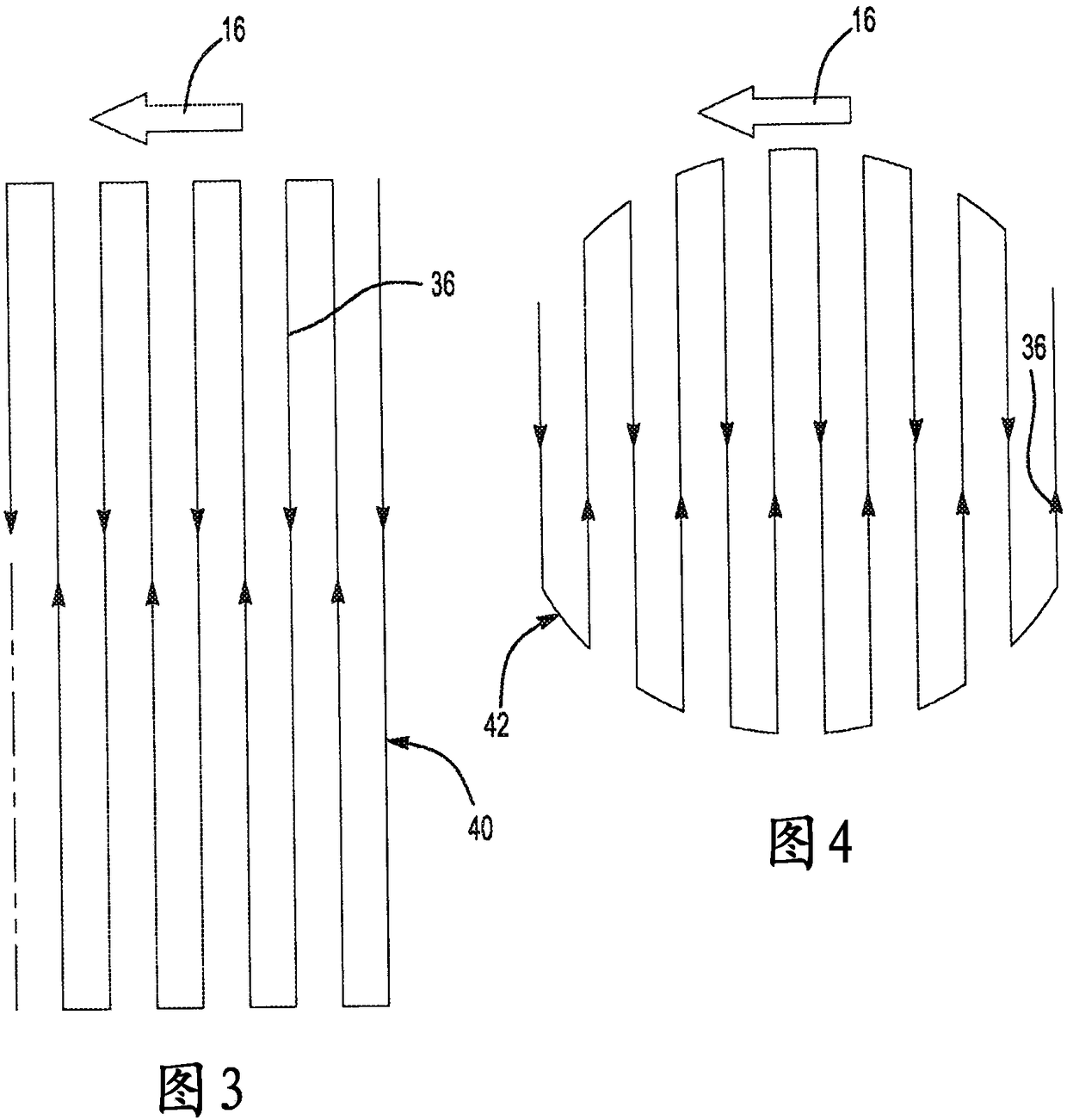

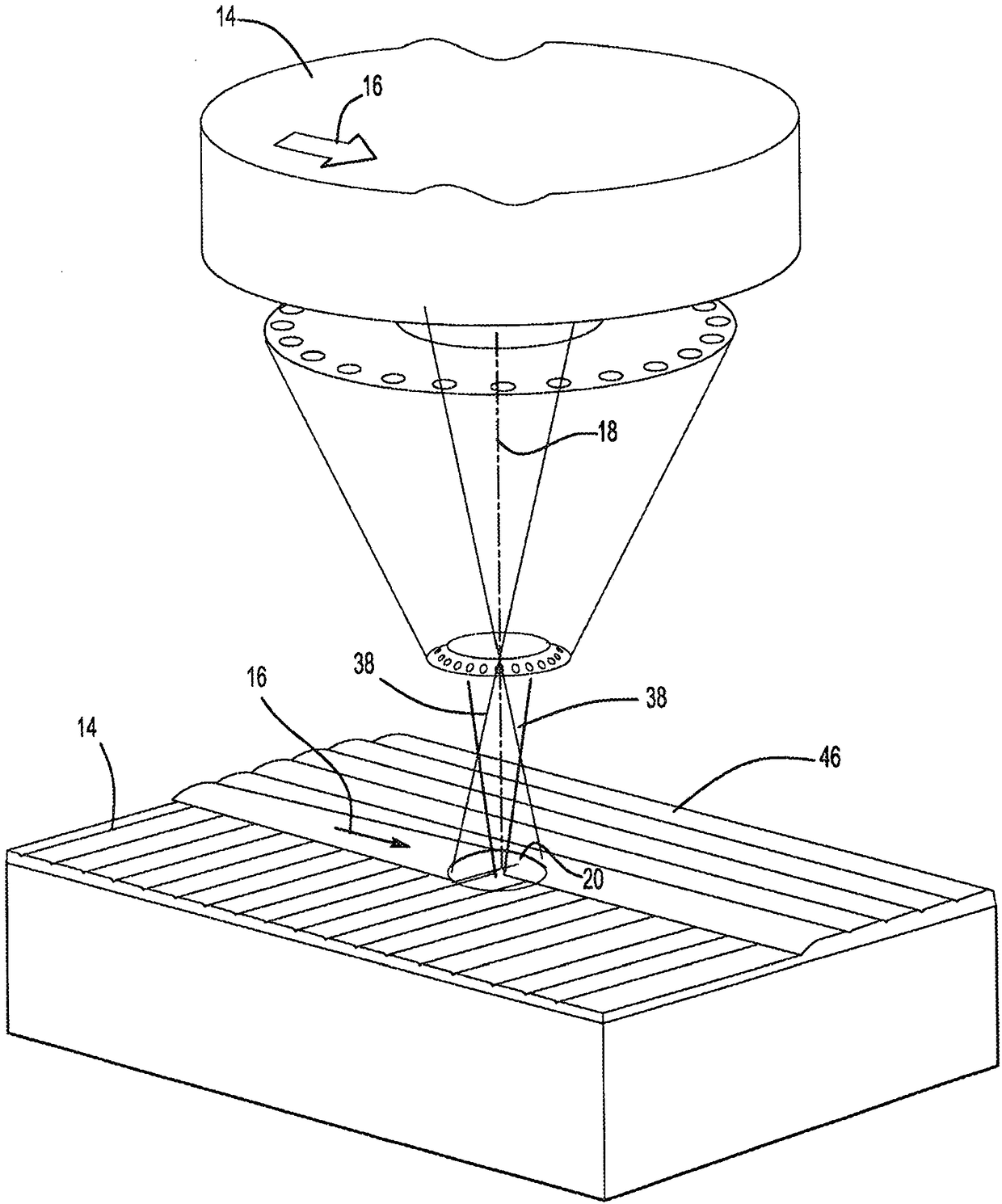

[0015] refer to figure 1 , an illustrative apparatus of the present invention is shown generally at 10 . The processing head 12 is mounted on a motion system 14 . The kinematic system 14 adopts a multi-way mechanical arm, a linear double-axis stage or can be moved along the direction indicated by the arrow 16 ( Figure 5 ) identifies the first path moving processing head 12 in the form of other equivalent means.

[0016] The processing head 12 generates a laser beam 18 in a manner explained further below. Laser beam 18 forms weld pool 20 on workpiece 22 using closed-loop processing in the manner set forth in US Patent No. 6,925,346, the disclosure of which is incorporated herein by reference. Nozzle 24 directs material received from material source 26 , eg, powdered metal, powdered ceramic, wire, and strip, into molten pool 20 .

[0017] like figure 2 As best shown, the processing head 12 includes a laser source 28 , such as a fiber optic, diode laser, and equivalent cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com