Drive units and units with coolers

A drive unit and unit technology, applied in electric components, machines/engines, liquid fuel engines, etc., can solve problems such as equipment technical costs of water circulation circuits, and achieve the effect of preventing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

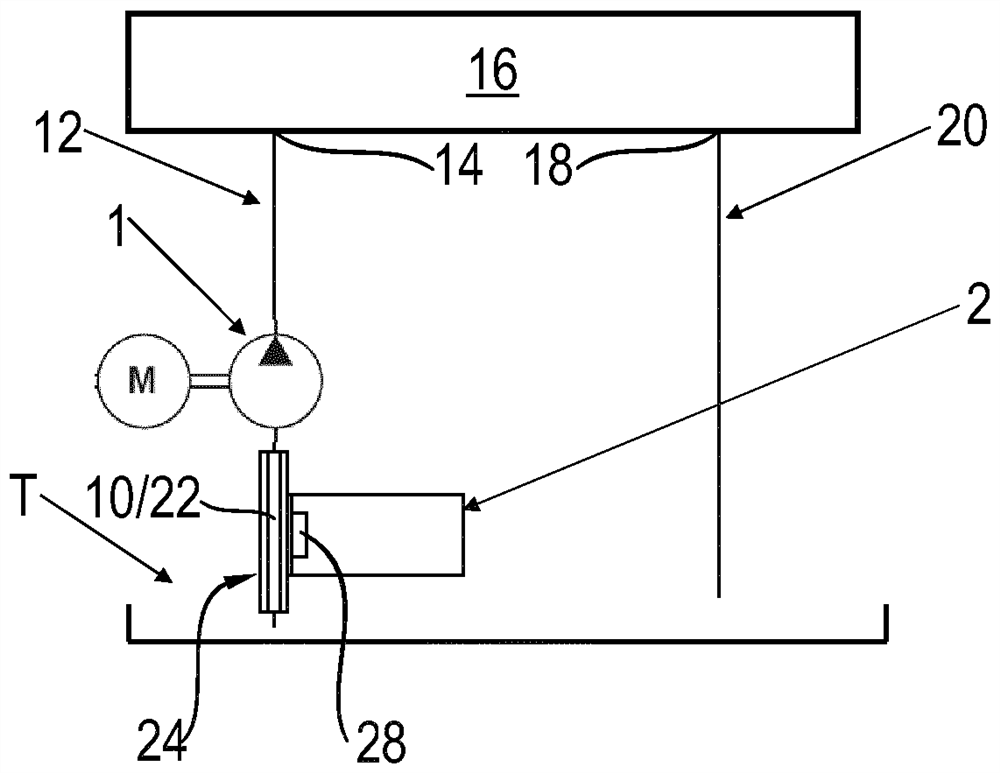

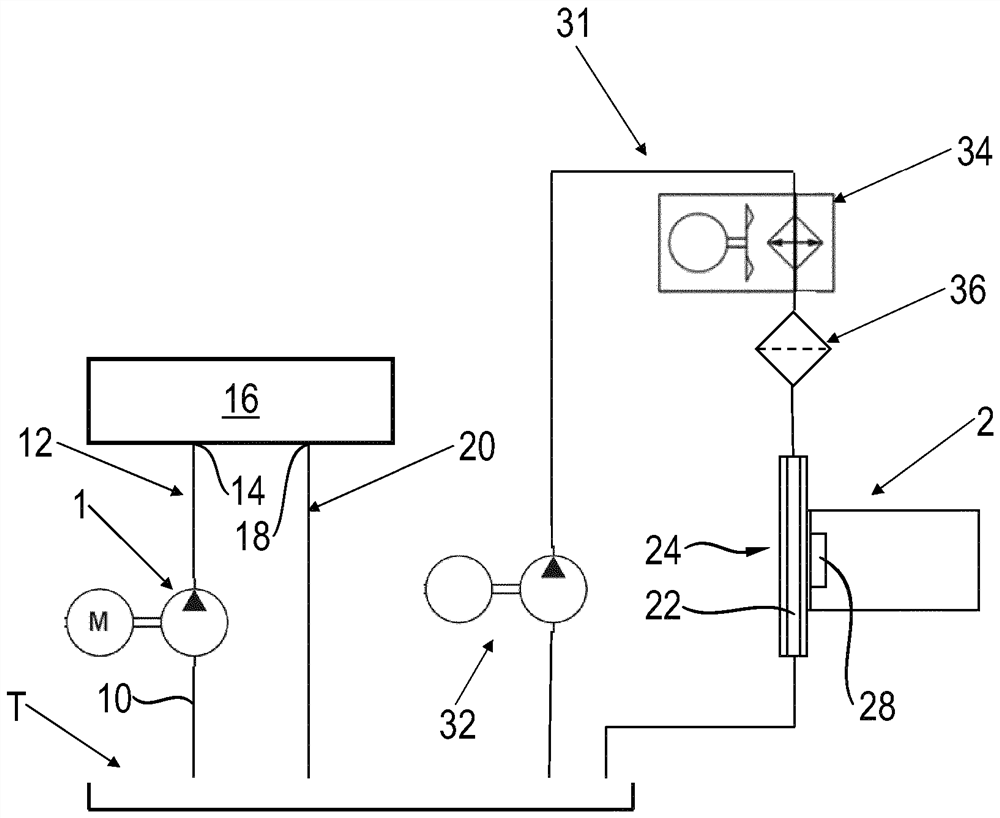

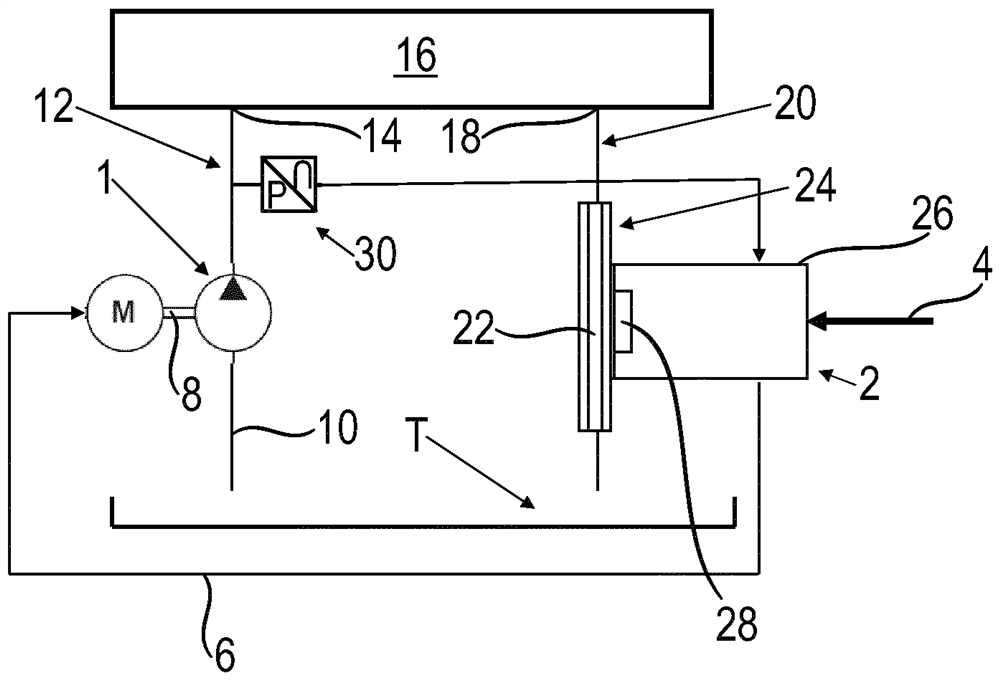

[0040] figure 1 A block diagram according to a first exemplary embodiment of the assembly according to the invention is shown. The assembly has a drive unit with an electric motor M and a hydrostatic pump 1 . The electric motor M of the drive unit is operated via a frequency converter 2 . Furthermore, the assembly has a tank T for a pressure medium, for example hydraulic oil.

[0041] The frequency converter 2 is connected between the power supply 4 and the electrical line 6 , whereby the electric motor M is supplied with power via the electrical line 6 at a set frequency and thus at a set speed. The pump 1 is thus driven by the electric motor M via the shaft 8 at a variable speed. In this case, the pump 1 draws pressure medium from the tank T via a suction line 10 and delivers the pressure medium via a supply line 12 to a load connection 14 on the high-pressure side of the unit. A load, which can be a cylinder, for example, is connected to this load connection 14 via a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com