Method for selecting cutting processing timing in manufacturing process of additive materials and subtractive materials

A manufacturing process and cutting technology, which is used in the selection of cutting timing in the process of adding and subtracting materials, to achieve the effects of improving production efficiency, shortening molding time, and avoiding unfavorable situations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

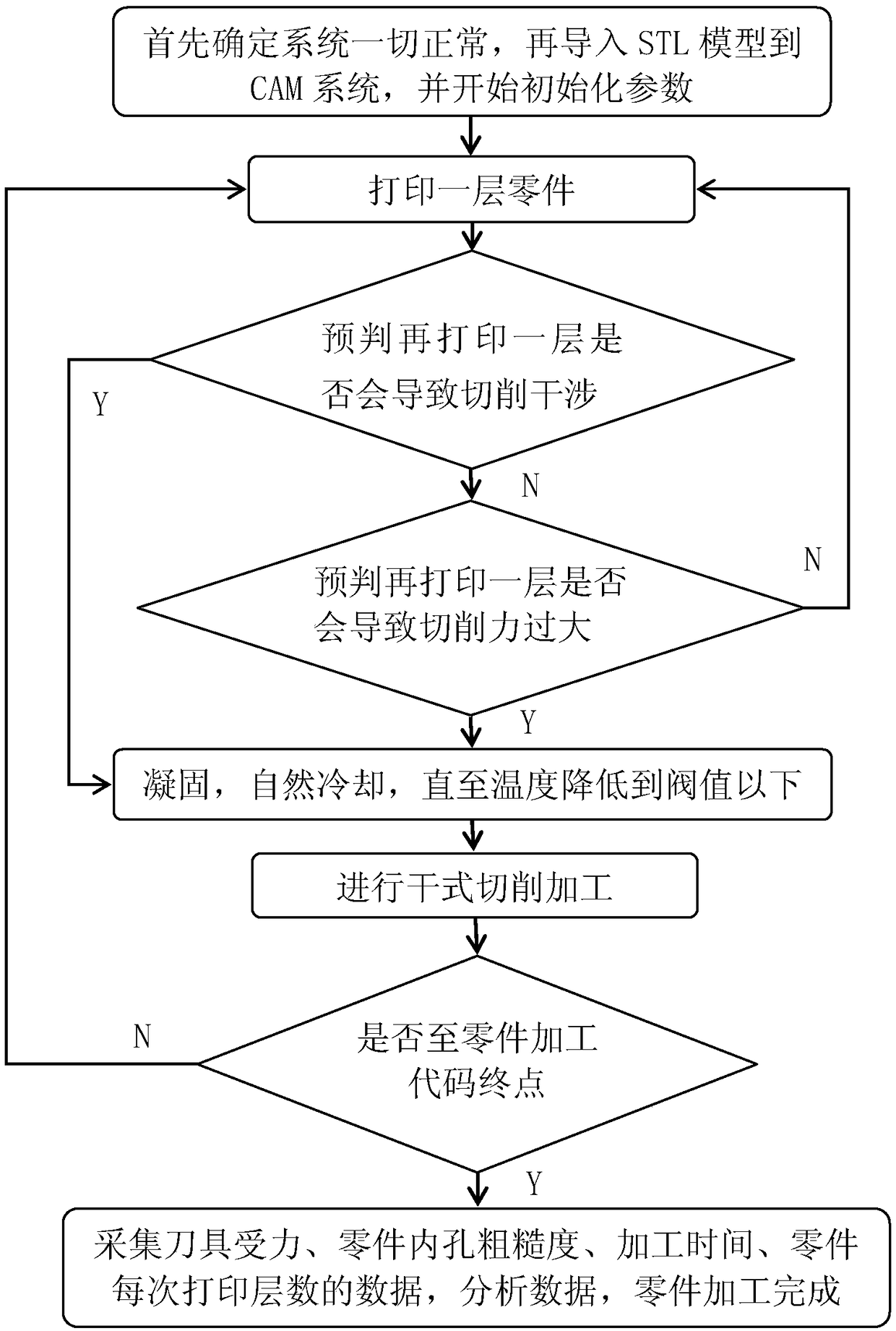

[0027] like figure 1 As shown, a method for selecting the cutting opportunity in the process of additive and subtractive material manufacturing includes the following steps:

[0028] S01. The printing material used in this experiment is titanium alloy. The room temperature of the experiment is kept at about 25°C. The tool type is selected as cemented carbide YG6. After the feed rate and tool speed, these parameters will not change during the whole experiment; the STL model is imported into the CAM system to initialize the processing parameters.

[0029] S02, install and fix a metal plate on the platform, the platform is on the mechanical arm of the six-axis robot, and the mechanical arm can move back and forth between the material addition station and the material reduction station.

[0030] S03. Cut out a high-precision reference plane on the sheet metal thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com