Wood plate cutting device with gear-type power mechanism

A technology of power mechanism and cutting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

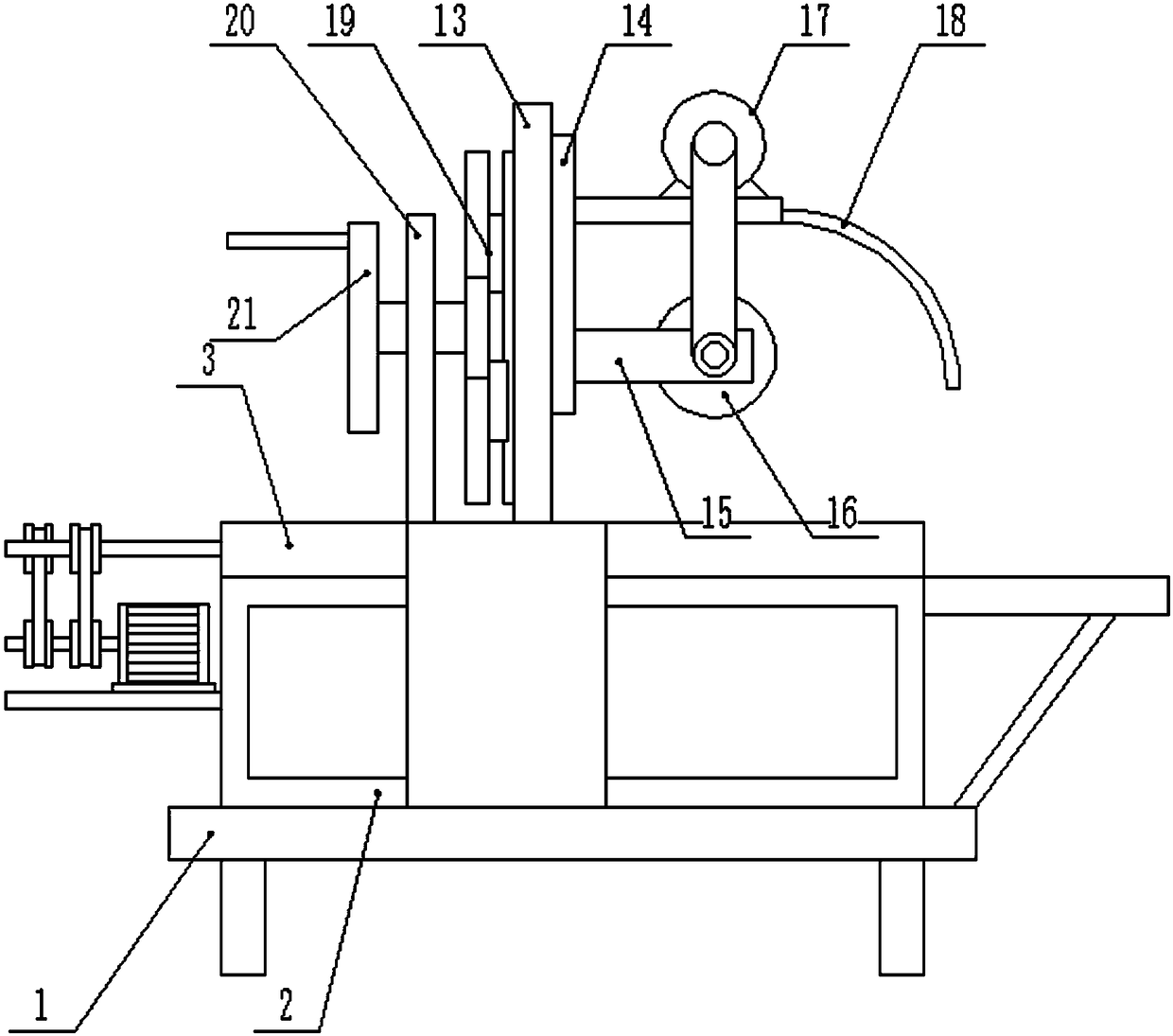

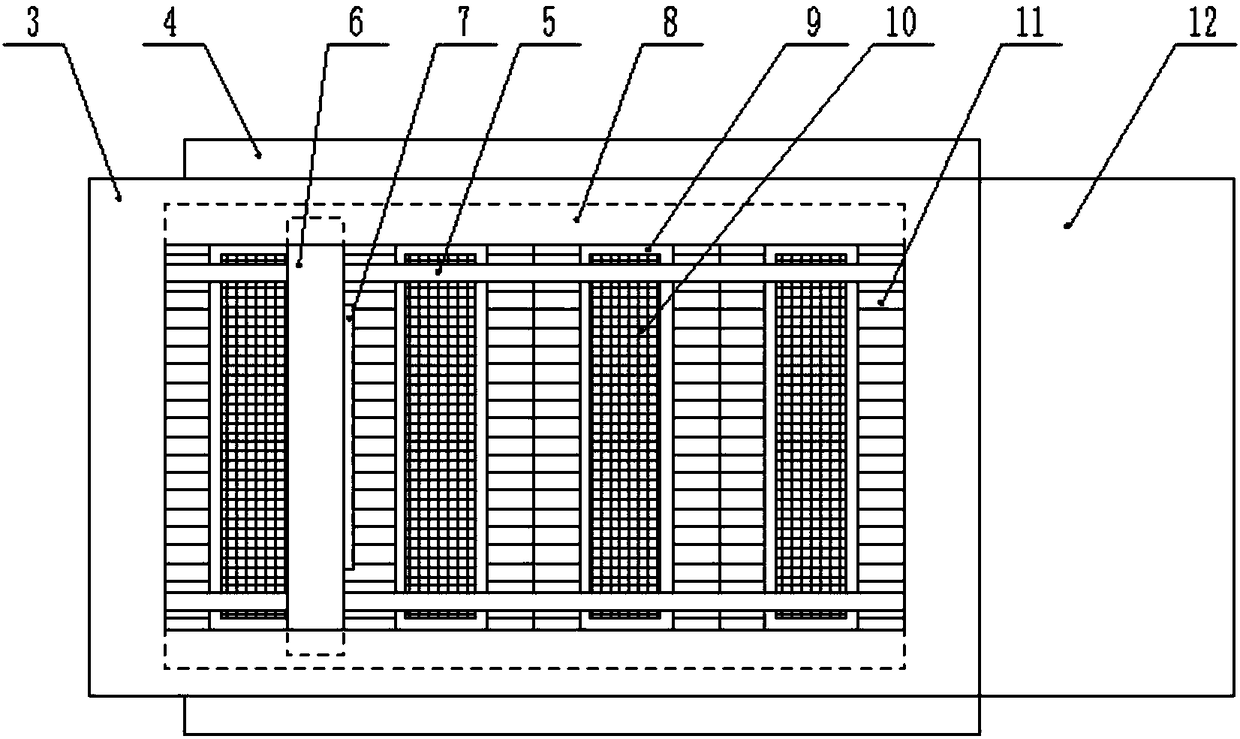

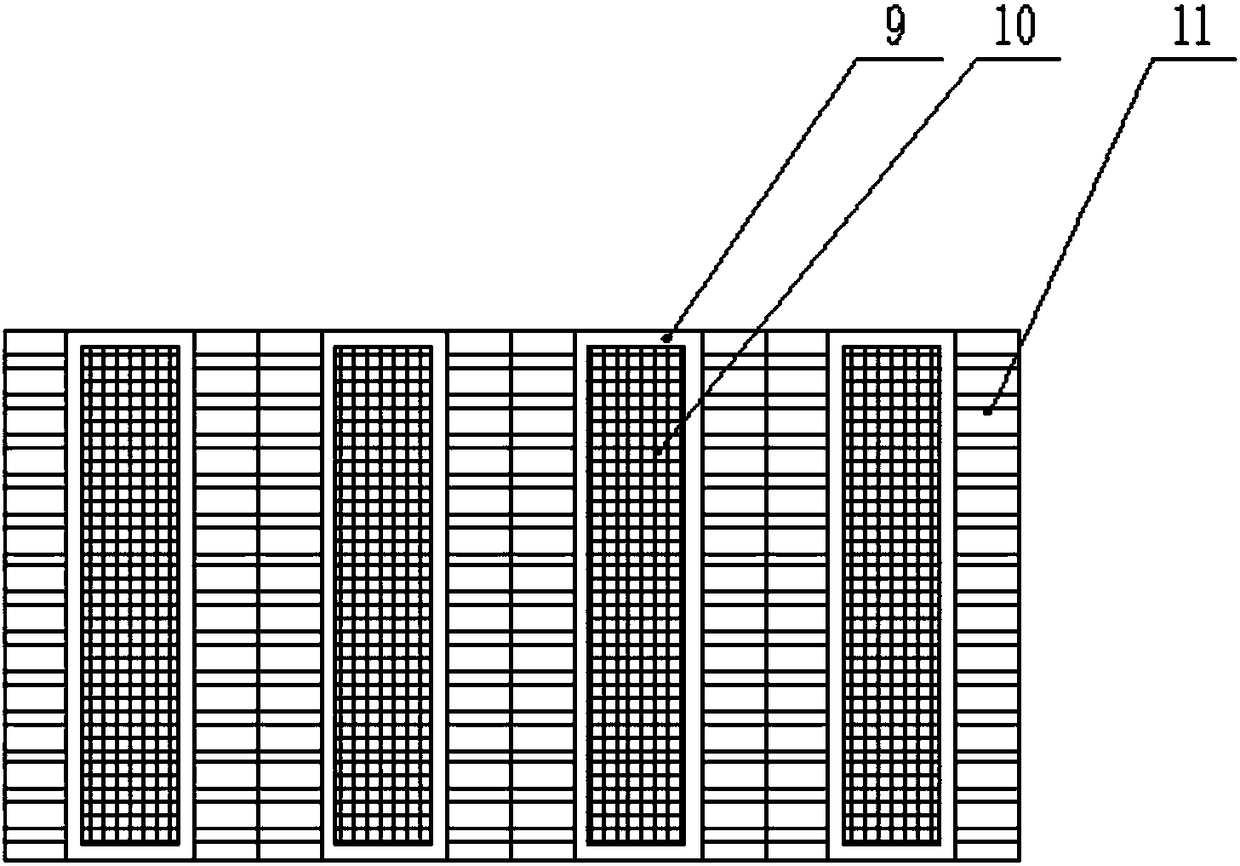

[0022] see Figure 1-4 , a wood cutting device with a gear type power mechanism, including a device body, the device body is provided with a support frame 1, a base 2 is provided above the support frame 1, and the base 2 and the support frame 1 are welded fixedly connected in a fixed way, the top of the base 2 is provided with a lateral movement structure 3, and the lateral movement structure 3 and the support frame 1 are fixedly connected through the action of screws, and the left side of the lateral movement structure 3 is provided with a drive mechanism, The right side of the lateral movement structure 3 is provided with a material receiving plate 12, and the material receiving plate 12 is fixedly connected with the side wall of the base 2 by welding, and the lateral movement structure 3 is provided with a carrier plate 4, and the carrier plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap