Anti-tearing steel wire rope core conveying belt

A technology of steel wire rope core and conveyor belt, applied in the field of conveyor belt, can solve the problems of increasing the thickness and self-weight of the conveyor belt, low tensile strength, low service life, etc., so as to improve the tensile strength and wear resistance, increase the transverse stretch Good strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

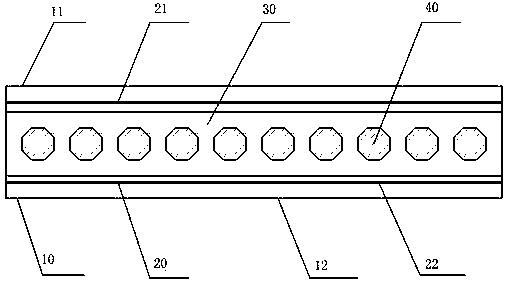

[0020] Such as figure 1 As shown, a schematic diagram of a longitudinal section of a tear-resistant steel cord conveyor belt of the present invention is provided, which includes an upper cover layer 11, a lower cover layer 12, an upper intermediate layer 21, a lower intermediate layer 22, an adhesive glue layer 30 and Wire rope 40. The covering layer 10 includes an upper covering layer 11 and a lower covering layer 12 , the upper covering layer 11 is closely attached to the upper middle layer 21 , and the lower covering layer 12 is closely attached to the lower middle layer 22 . The middle layer 20 includes an upper middle layer 21 and a lower middle layer 22, bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com