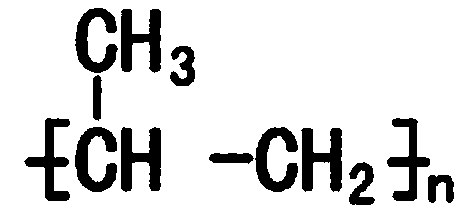

Weather-resistant polystyrene material

A technology of weather-resistant polypropylene and polypropylene materials, which is applied in the field of polypropylene material production, can solve the problems of loss of basic physical properties and easy aging, and achieve the effects of improving weather resistance and anti-oxidation performance, low cost, and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take each raw material respectively by weight ratio as follows:

[0021] Polypropylene raw material: 55

[0022] Titanium dioxide: 1.5

[0023] Inorganic filler (calcium carbonate): 130

[0024] Dispersant lubricant (TAS-2A): 0.4

[0025] UV absorber (2-hydroxy-4-n-octyloxybenzophenone): 5

[0026] Light Stabilizer: 5

[0027] Antioxidant (copolymer of ethylene-octene): 8

[0028] Colorants: 2

[0029] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

[0030] Experimental results:

[0031]

[0032] The above test results show that the w...

Embodiment 2

[0034] (1) Take each raw material respectively by weight ratio as follows:

[0035] Polypropylene raw material: 62

[0036] Titanium dioxide: 2.1

[0037] Inorganic filler (calcium carbonate): 175

[0038] Dispersant lubricant (TAS-2A): 0.5

[0039] UV absorber (2-hydroxy-4-n-octyloxybenzophenone): 8.6

[0040] Light stabilizer: 8.6

[0041] Antioxidant (copolymer of ethylene-octene): 11.5

[0042] Colorant: 3.0

[0043] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

[0044] Experimental results:

[0045]

[0046] The above test results show th...

Embodiment 3

[0048] (1) Take each raw material respectively by weight ratio as follows:

[0049] Polypropylene raw material: 68

[0050] Titanium dioxide: 2.5

[0051] Inorganic filler (calcium carbonate): 180

[0052] Dispersant lubricant (TAS-2A): 0.5

[0053] UV absorber (2-hydroxy-4-n-octyloxybenzophenone): 7.5

[0054] Light Stabilizer: 7

[0055] Antioxidant (copolymer of ethylene-octene): 13

[0056] Colorants: 2

[0057] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

[0058] Experimental results:

[0059]

[0060] The above test results show that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com