Fluorescent powder material for near-infrared LED (Light Emitting Diode) and preparation method thereof

A phosphor, near-infrared technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of less research on near-infrared fluorescent materials, and achieve the effects of simple preparation method, wide excitation range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of phosphor material of near-infrared LED, the chemical expression of this phosphor is Y 0.95 al 2.79 (BO 3 ) 4 : 0.21Cr, 0.05Yb, its preparation steps are as follows:

[0031] 1. Weigh raw material Y 2 o 3 0.00475mol, Al 2 o 3 0.01395mol,H 3 BO 3 0.056mol, Cr 2 o 3 0.00105mol, Yb 2 o 3 0.00025mol;

[0032] 2. After fully mixing the weighed raw materials, sinter in air at 1250°C for 10 hours to obtain a roasted product;

[0033] 3. After fully grinding the obtained roasted product into powder and passing through a 200-mesh sieve, wash with deionized water for 3 times, and dry at 80°C to obtain the Y powder of the present invention. 0.95 al 2.79 (BO 3 ) 4 : 0.21Cr, 0.05Yb near-infrared phosphor.

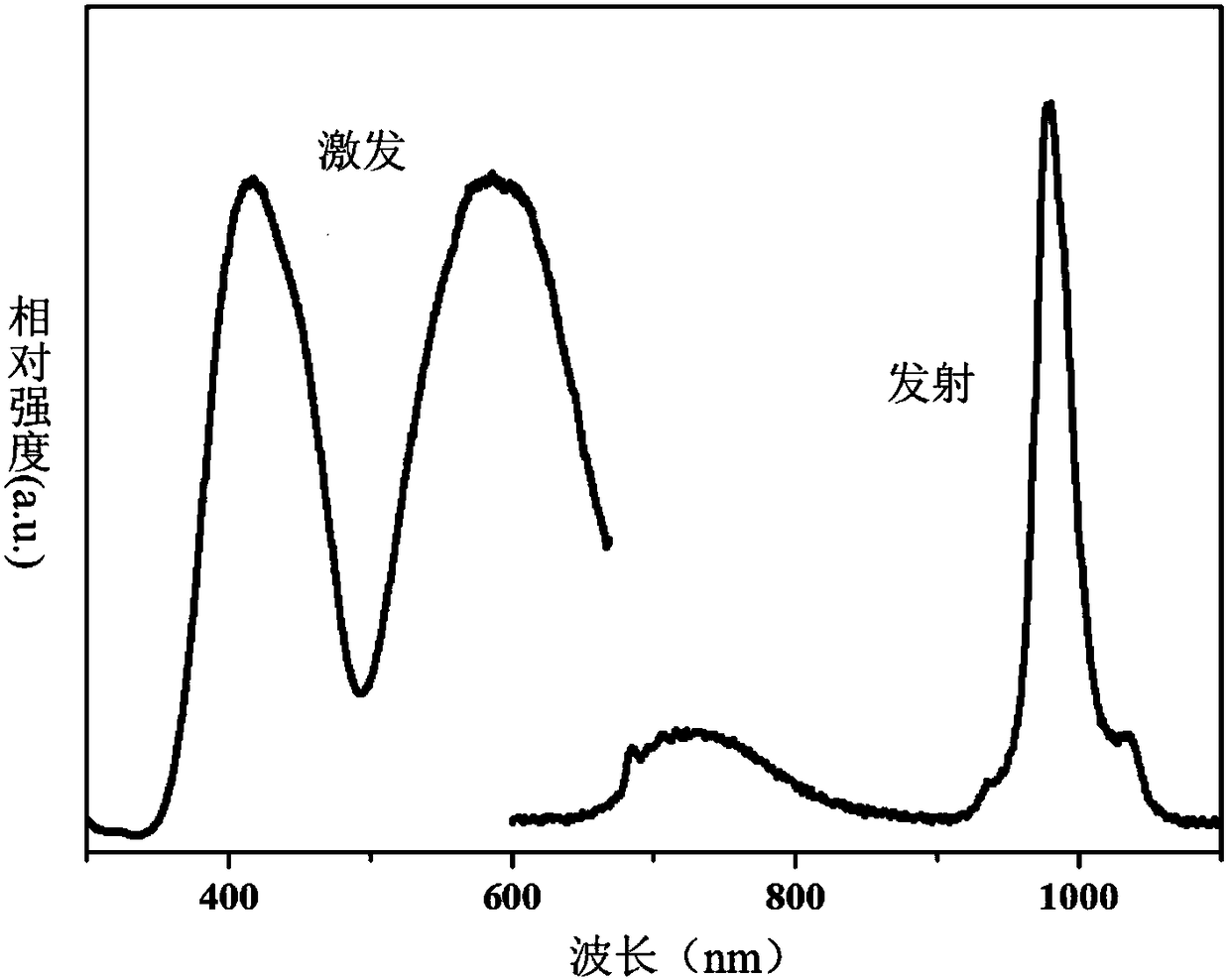

[0034] The excitation spectrum and emission spectrum of the fluorescent powder prepared in this embodiment are as attached figure 1 shown.

Embodiment 2

[0036] A kind of phosphor material of near-infrared LED, the chemical expression of this phosphor is Gd 0.95 al 2.79 (BO 3 ) 4 : 0.21Cr, 0.05Yb, its preparation steps are as follows:

[0037] 1. Weigh the raw material Gd 2 o 3 0.00475mol, Al 2 o 3 0.01395mol,H 3 BO 3 0.056mol, Cr 2 o 3 0.00105mol, Yb 2 o 3 0.00025mol;

[0038] 2. The weighed raw material and 10% AlF by weight of the raw material 3 After fully mixing as a flux, sintering at 1200°C in air for 5h, then fully grinding the sintered product, and then firing twice at 1200°C in air for 10h to obtain a roasted product;

[0039] 3. Grind the roasted product into powder and pass through a 200-mesh sieve, wash with deionized water for 3 times, and dry at 100°C to obtain the near-infrared phosphor Gd of the present invention 0.95 al 2.79 (BO 3 ) 4 : 0.21Cr, 0.05Yb.

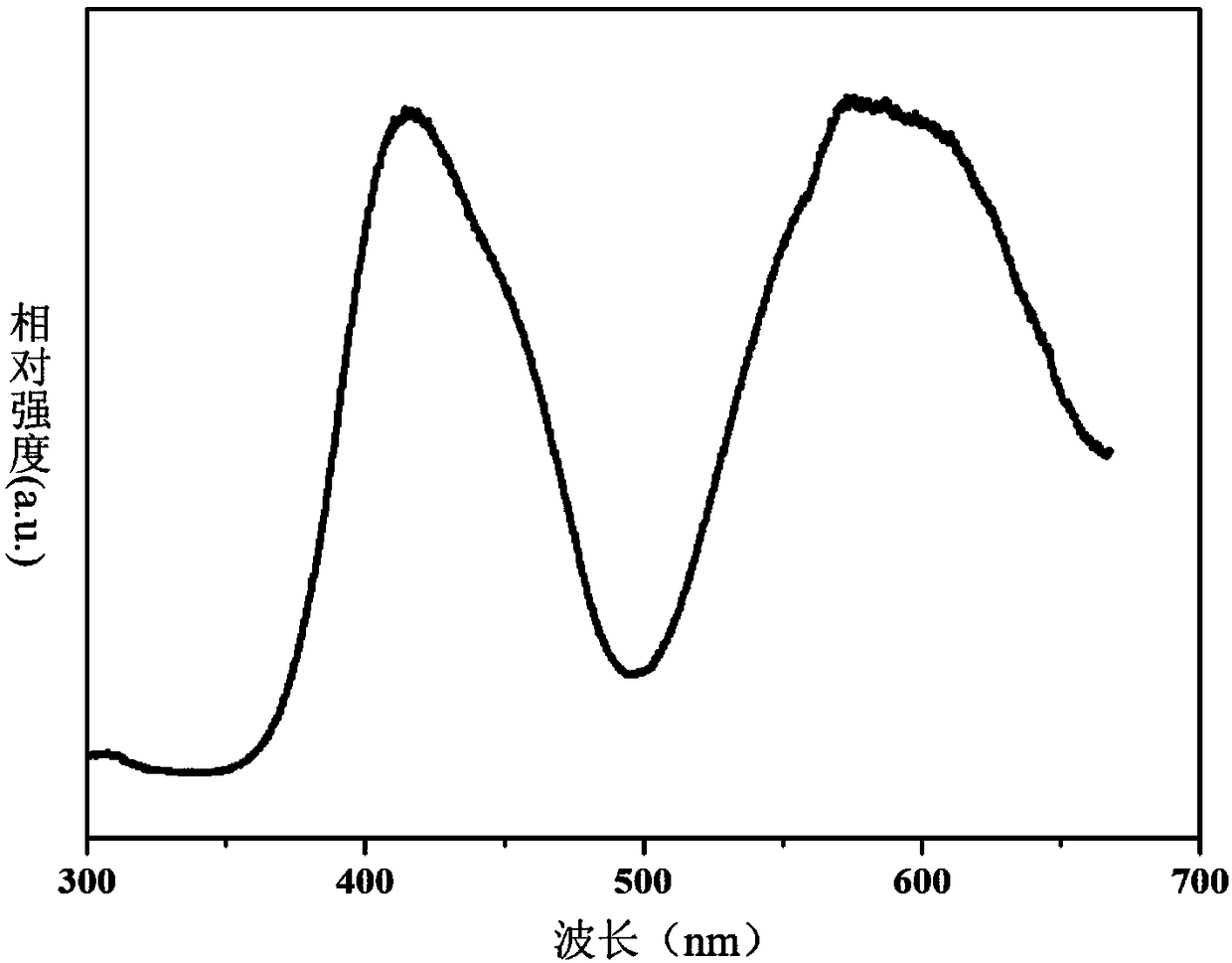

[0040] The excitation spectrum and emission spectrum of the fluorescent powder prepared in this embodiment are as attached figure 2 ,...

Embodiment 3

[0042] A kind of phosphor material of near-infrared LED, the chemical expression of this phosphor is Lu 0.98 al 2.73 (BO 3 ) 4 : 0.27Cr, 0.02Yb, its preparation steps are as follows:

[0043] 1. Weigh the raw material Lu 2 o 3 0.0049mol, Al 2 o 3 0.01365mol,H 3 BO 3 0.064mol, Cr 2 o 3 0.00135mol, Yb 2 o 3 0.0001mol;

[0044] 2. The weighed raw material and 5% AlF by weight of the raw material 3 After fully mixing as a flux, sinter in air at 1300°C for 10 hours to obtain a calcined product;

[0045] 3. Fully grind the calcined product into powder and pass through a 200-mesh sieve, wash with deionized water for 3 times, and dry at 120°C to obtain the near-infrared fluorescent powder Lu of the present invention. 0.98 al 2.73 (BO 3 ) 4 : 0.27Cr, 0.02Yb.

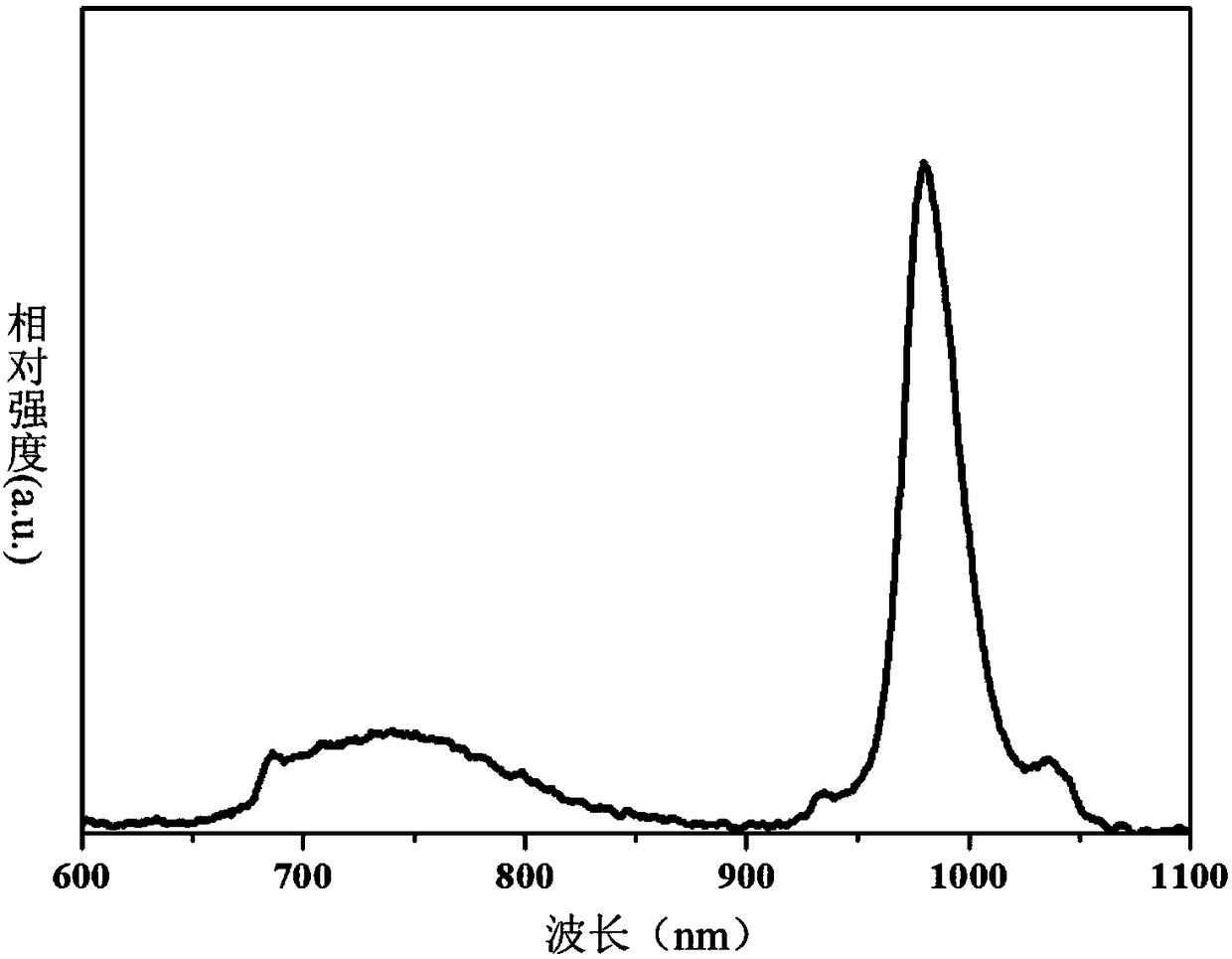

[0046] The excitation spectrum and emission spectrum of the fluorescent powder prepared in this embodiment are as attached Figure 4 , 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com