Large-sized wear resistant steel with high uniformity and manufacturing method thereof

A manufacturing method and large-scale technology, applied in the field of alloy steel, can solve the problems of low impact toughness, environmental pollution, forming failure, etc., and achieve the effects of improving stability, simple production process and excellent plate shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

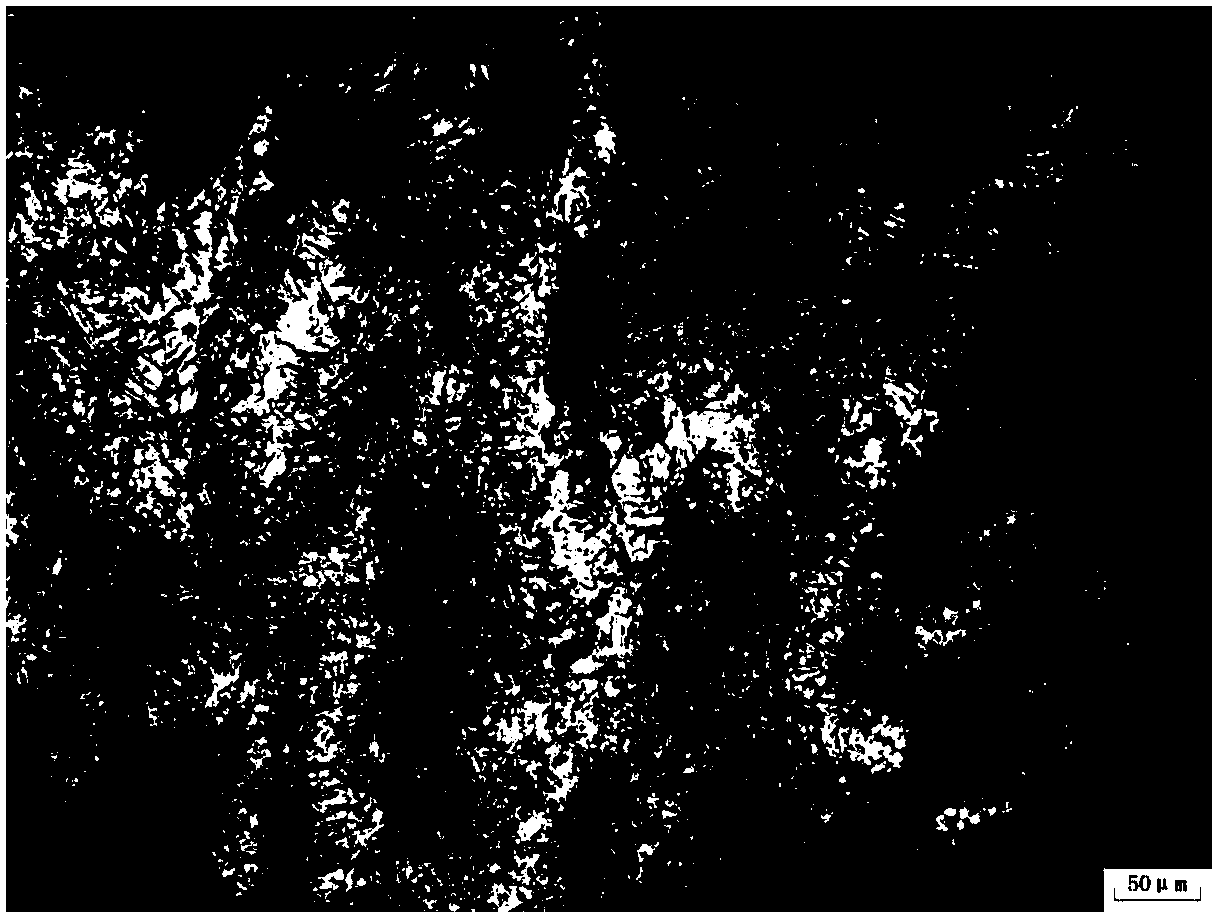

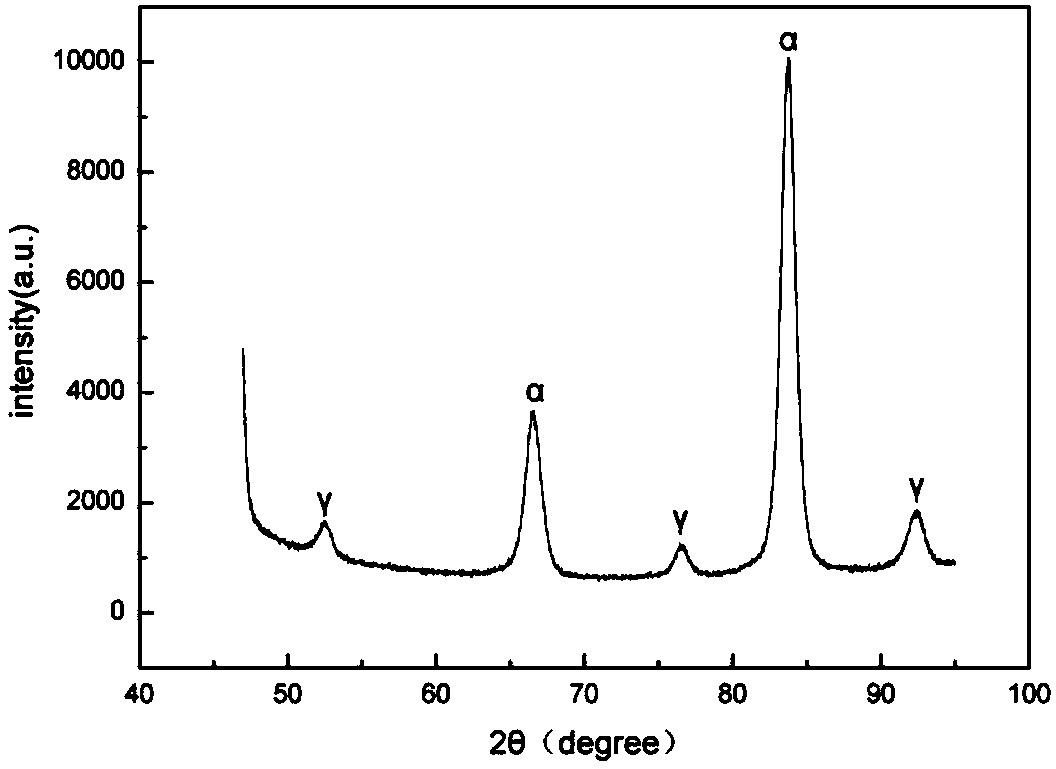

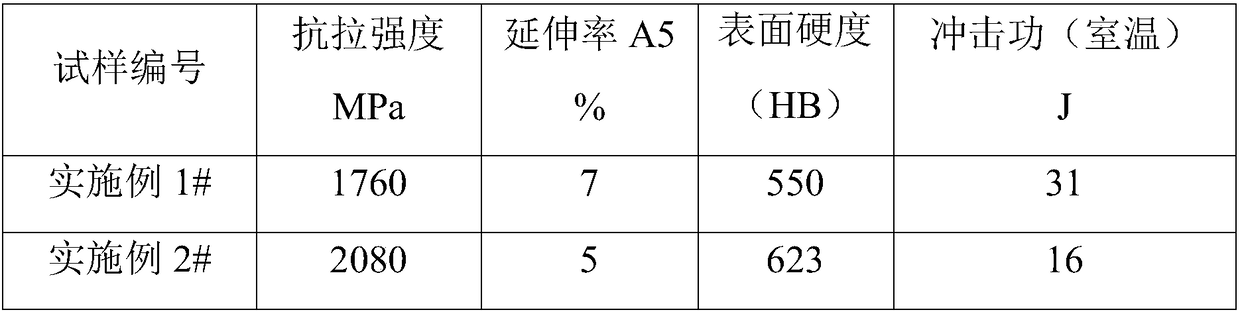

Embodiment 1

[0044] The chemical composition of this embodiment is C: 0.25%, Si: 0.43%, Mn: 4.50%, Cr: 1.22%, Ni: 1.25%, Mo: 0.31%, S: 0.005%, P: 0.005 %, the balance is Fe and unavoidable impurities. The steel plate manufacturing process includes: converter smelting, LF refining, RH refining, slab continuous casting; medium and heavy plate rolling mills are used for rolling, in which the heating temperature is 1200°C, the final rolling temperature is 1000°C, the rolling thickness is 300mm, and air cooling after rolling. The tensile strength of the obtained steel plate is 1760Mpa, the elongation is 7%, the surface hardness is HB550, and the impact energy at room temperature is 31J.

Embodiment 2

[0046] The chemical composition of the present invention is C: 0.32%, Si: 0.48%, Mn: 5.02%, Cr: 1.11%, Ni: 1.31%, S: 0.005%, P: 0.015%, and the balance is Fe and unavoidable impurities. Manufacturing process: converter smelting, LF refining, die casting; rolling is carried out by a plate rolling mill, in which the heating temperature is 1220°C, the final rolling temperature is 1050°C, the rolling thickness is 350mm, and air-cooled after rolling. The tensile strength of the obtained steel plate is 2080Mpa, the elongation is 5%, the surface hardness is HB623, and the impact energy at room temperature is 16J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com