Fastener hot-dip galvanizing production technology

A production process and technology of fasteners, applied in the field of hot-dip galvanizing production process of fasteners, can solve the problems of high galvanizing zinc consumption, high production cost, large energy consumption, etc., to reduce investment costs, improve adhesion, The effect of improving uniformity

Active Publication Date: 2018-06-12

徐州瑞马智能技术有限公司

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, with the rapid development of high-voltage power transmission, transportation, and communication, there are increasingly higher requirements for fastener protection. At the same time, the demand for hot-dip galvanized parts is also increasing. In the existing hot-dip galvanizing process, not only galvanized The zinc consumption is high, and the energy consumption is also large, resulting in the current situation of high production costs

In addition, the current hot-dip galvanizing process has slow galvanizing efficiency and unsatisfactory galvanizing effect, which can no longer meet the needs of production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

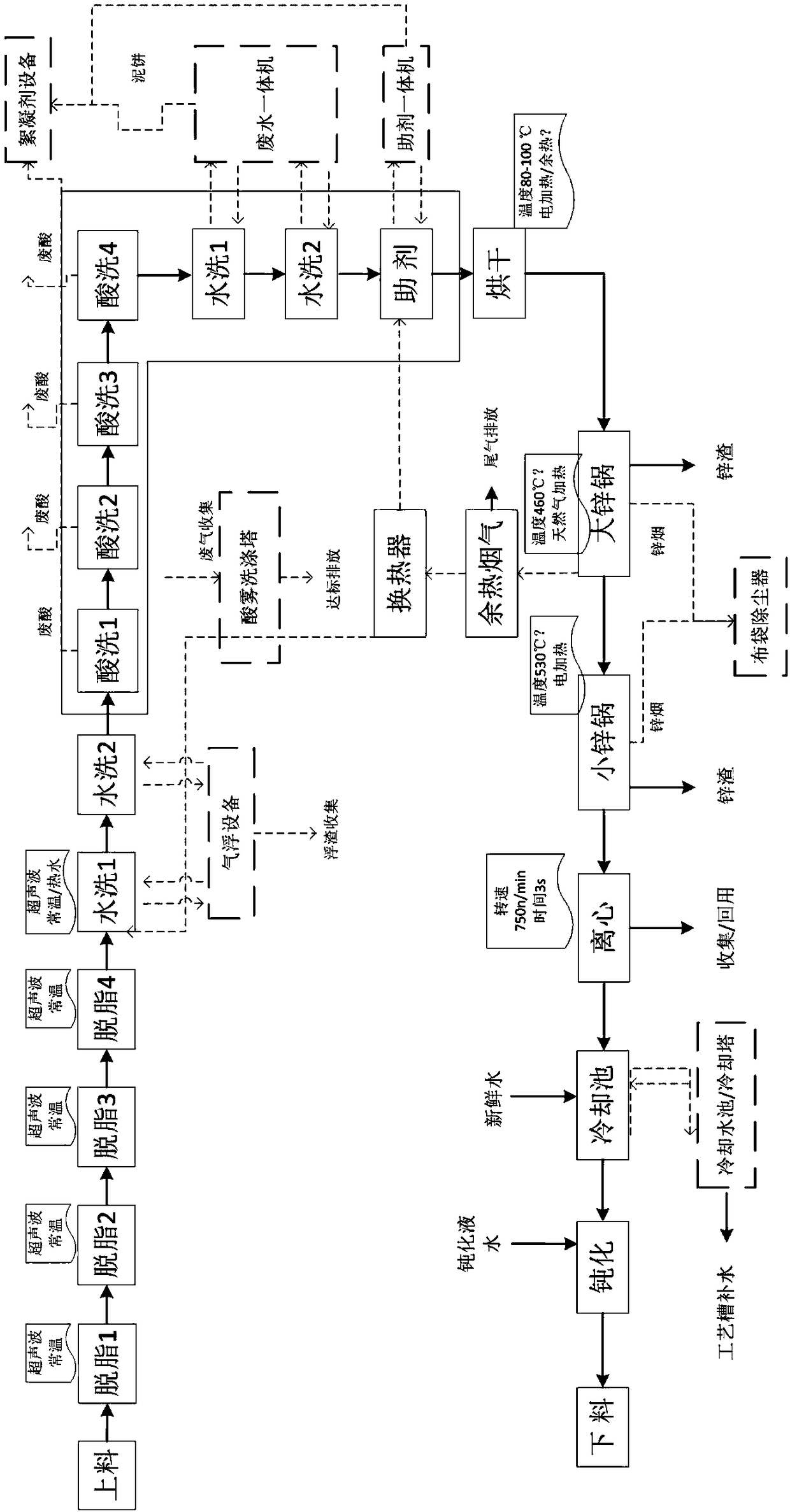

[0028] like figure 1 As shown, a production process of hot-dip galvanizing for fasteners includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A fastener hot-dip galvanizing production technology comprises the steps of chemical degreasing: applying degreasing agents and ultrasonic wave to a fastener jointly in a degreasing tank which is provided with an ultrasonic generator, wherein the degreasing temperature is 20-40 DEG C, and the degreasing time is 1 min; washing for first time; washing for second time; acid pickling; washing for third time; dipping in assistant plating solvents; drying and preheating: drying and preheating the fastener, and the drying temperature is 80-100 DEG C; galvanizing for first time: immersing the fastenerin a large galvanizing pot, and the galvanizing temperature is 440-460 DEG C; drying of a channel: preheating a transfer channel between the large galvanizing pot and a small galvanizing pot by fluegas waste heat of the large galvanizing pot; galvanizing for second time: immersing the fastener in the small galvanizing pot, and the galvanizing temperature is 500-540 DEG C; centrifugation; cooling; and passivation. Compared with a simple design galvanizing method, the technology has the advantages that the galvanizing capacity is improved obviously, and the investment cost and the operation cost are reduced obviously; the production efficiency is high, and the galvanizing effect is good; and the zinc consumption and energy consumption of the technology are both lower.

Description

technical field [0001] The invention relates to the technical field of fastener processing, in particular to a production process of hot-dip galvanizing for fasteners. Background technique [0002] In the prior art, in order to improve corrosion resistance and brightness, fasteners are generally treated by hot-dip galvanizing process, and the fasteners are immersed in molten zinc liquid to obtain a metal coating. In recent years, with the rapid development of high-voltage power transmission, transportation, and communication, there are increasingly higher requirements for fastener protection. At the same time, the demand for hot-dip galvanized parts is also increasing. In the existing hot-dip galvanizing process, not only galvanized Zinc consumption is high, and energy consumption is also large, thus resulting in the current situation of high production costs. In addition, the current hot-dip galvanizing process has slow galvanizing efficiency and unsatisfactory galvanizing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C2/06

CPCC23C2/06

Inventor 戴海峰王彪陈雷蔡朋李孝芳

Owner 徐州瑞马智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com