Hollow acrylic composite plate

An acrylic board and acrylic technology, applied in building components, building insulation materials, sound insulation, etc., can solve the problems of laborious handling, transportation and installation, heavy insulating glass weight, and potential safety hazards, and achieve good noise reduction effect and good structural strength , strong security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

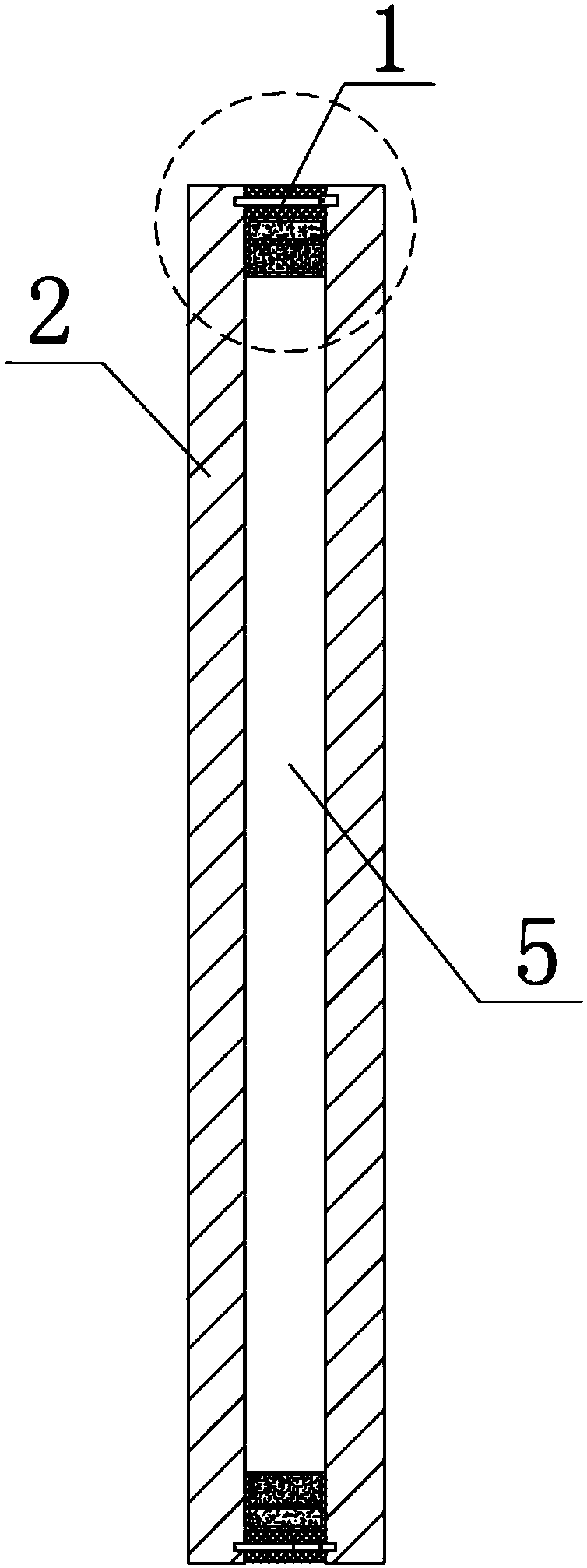

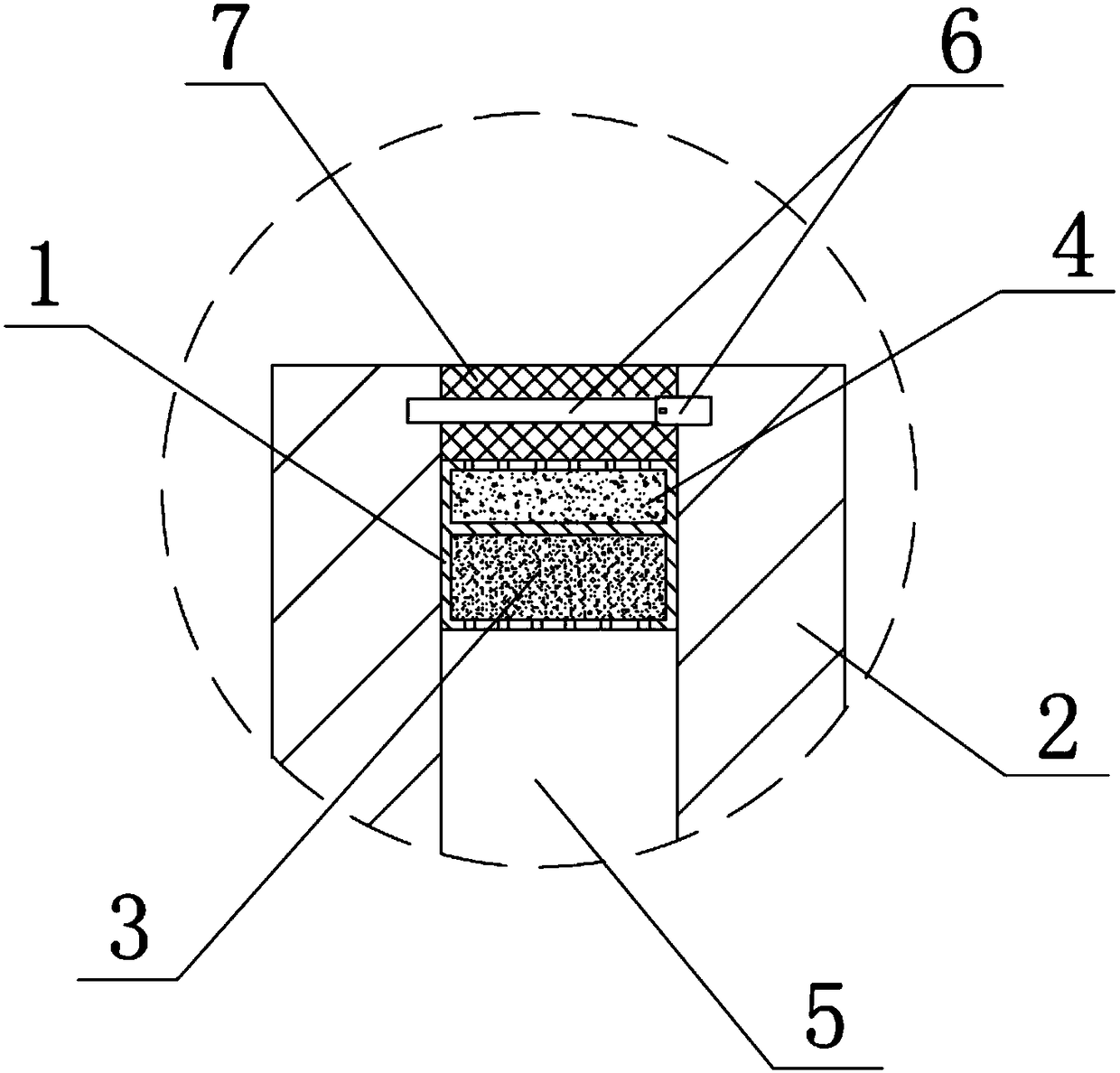

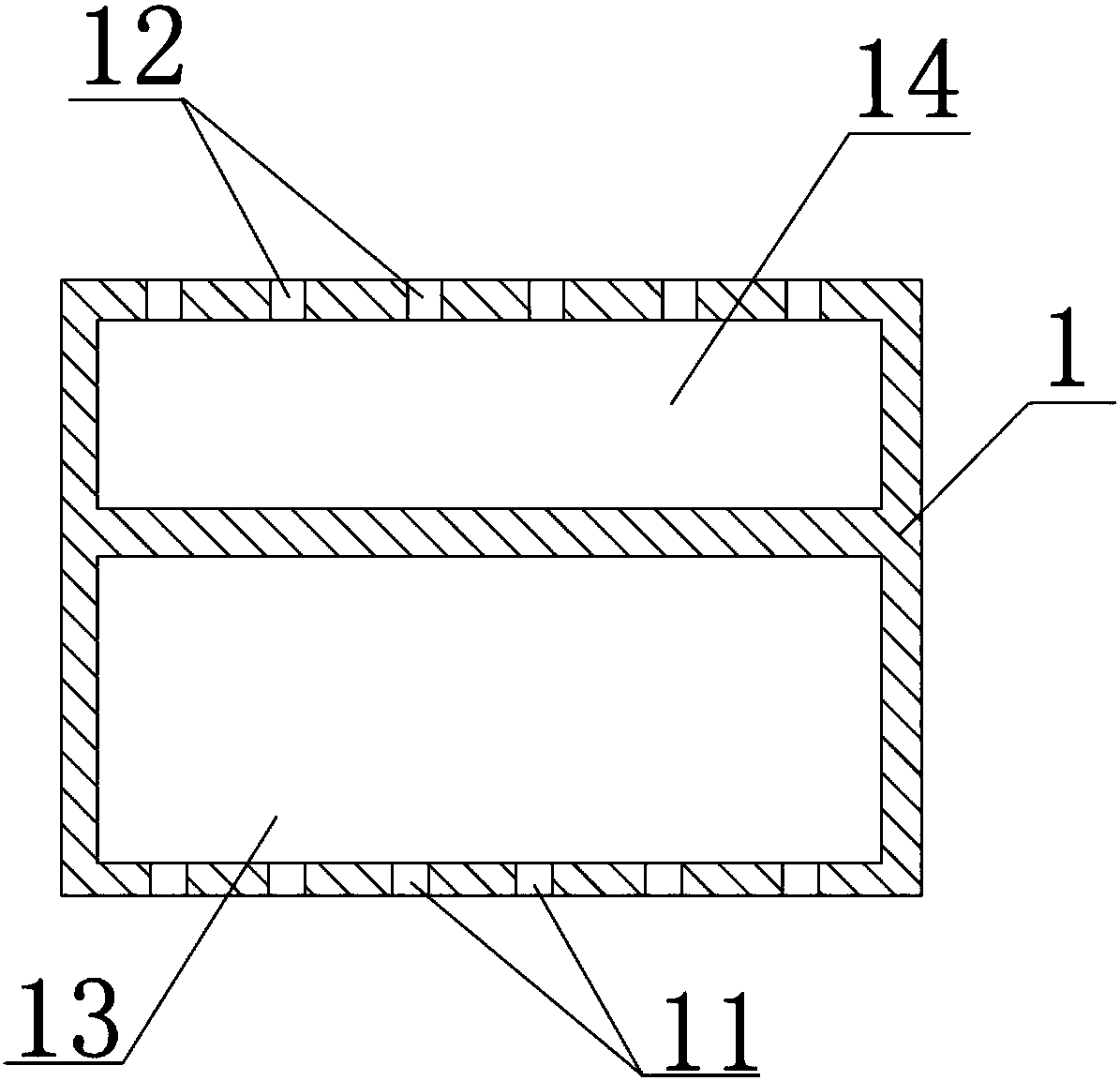

[0019] The invention provides a hollow acrylic composite board, such as figure 1 and figure 2 As shown, it includes a partition frame 1 and two acrylic panels 2. The partition frame 1 is usually made of aluminum, such as image 3 As shown, the partition frame 1 is surrounded by a square tube, the partition frame 1 is provided with a first cavity 13 and a second cavity 14, the second cavity 14 is located on the outside of the first cavity 13, the partition frame 1 The side close to the cavity 5 is provided with a first through hole 11, the outer wall of the second cavity 14 is provided with a second through hole 12, the square tube is filled with a molecular sieve adsorbent 3, and the second cavity 14 is filled with a composite resistive material. water material4. The frame 1 is set between two adjacent acrylic plates 2, and the frame 1 is matched with the acrylic plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com