Hydraulic automatic gearbox gear-shifting control method

A technology of automatic transmission and control method, applied in the direction of transmission control, elements with teeth, belt/chain/gear, etc., can solve the problem of single shifting mode of hydraulic automatic transmission, and achieve the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, contents and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the examples.

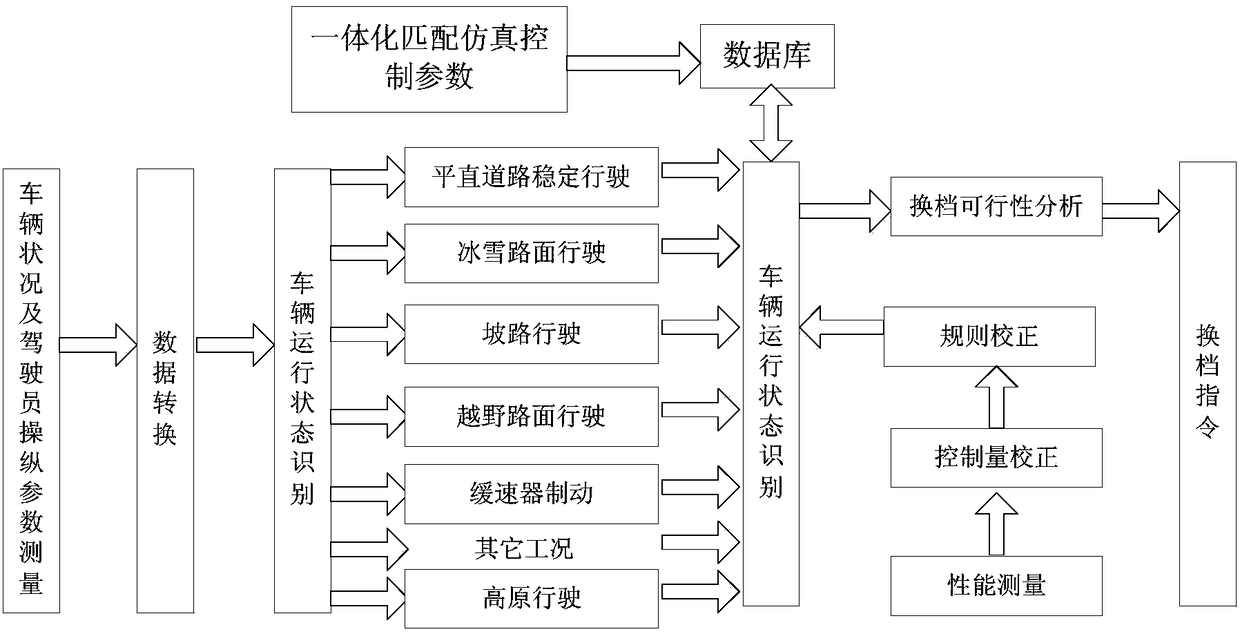

[0013] The invention provides a gear shift control method of a hydraulic automatic transmission, which specifically includes the following steps:

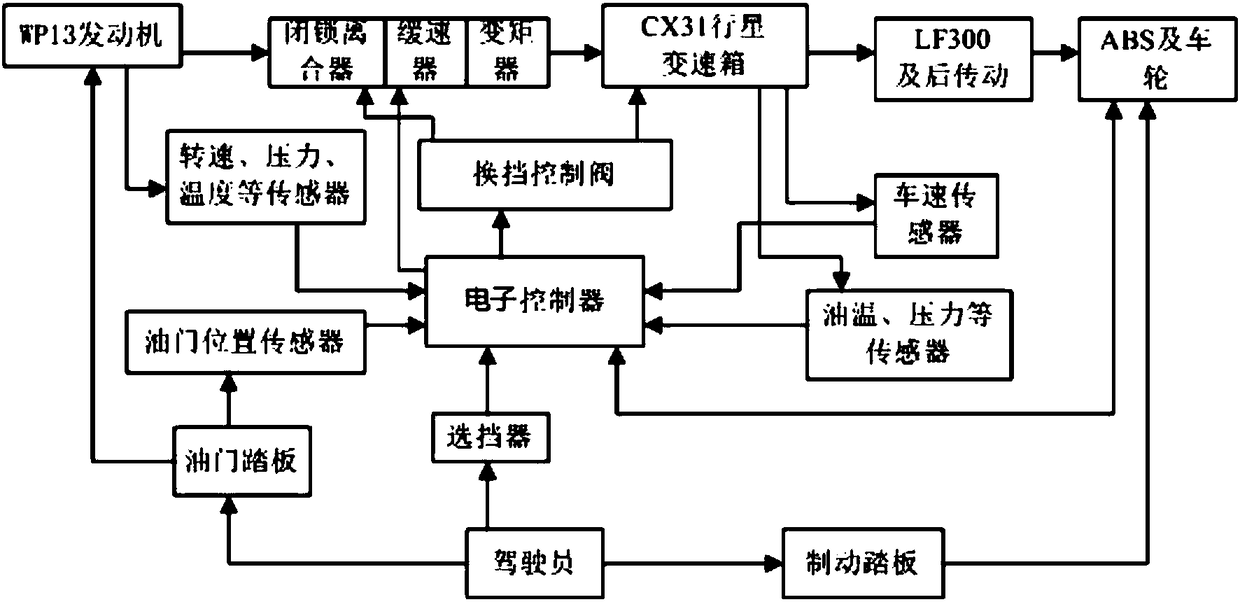

[0014] S1. Under different road conditions, the vehicle status and driver's manipulation parameters are collected through sensors, and the two shift control parameters of vehicle speed and accelerator pedal position (accelerator opening) are used as the main control parameters, including engine oil temperature, water temperature, and system pressure. , brake pedal signal, steering signal, transfer case gear, environmental parameters, road surface conditions, load and other control parameters; the sensors include accelerator position sensor, speed, pressure, temperature sensor, oil temperature, pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com