Bamboo joint type fiber laser hydrophone packaging structure and assembling method thereof

A packaging structure and fiber laser technology, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of flat low-frequency response and sensitivity drop, affecting the low-frequency response characteristics of fiber laser hydrophones, etc., to overcome Susceptible to electromagnetic environment and long-term transmission attenuation, high sensitivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

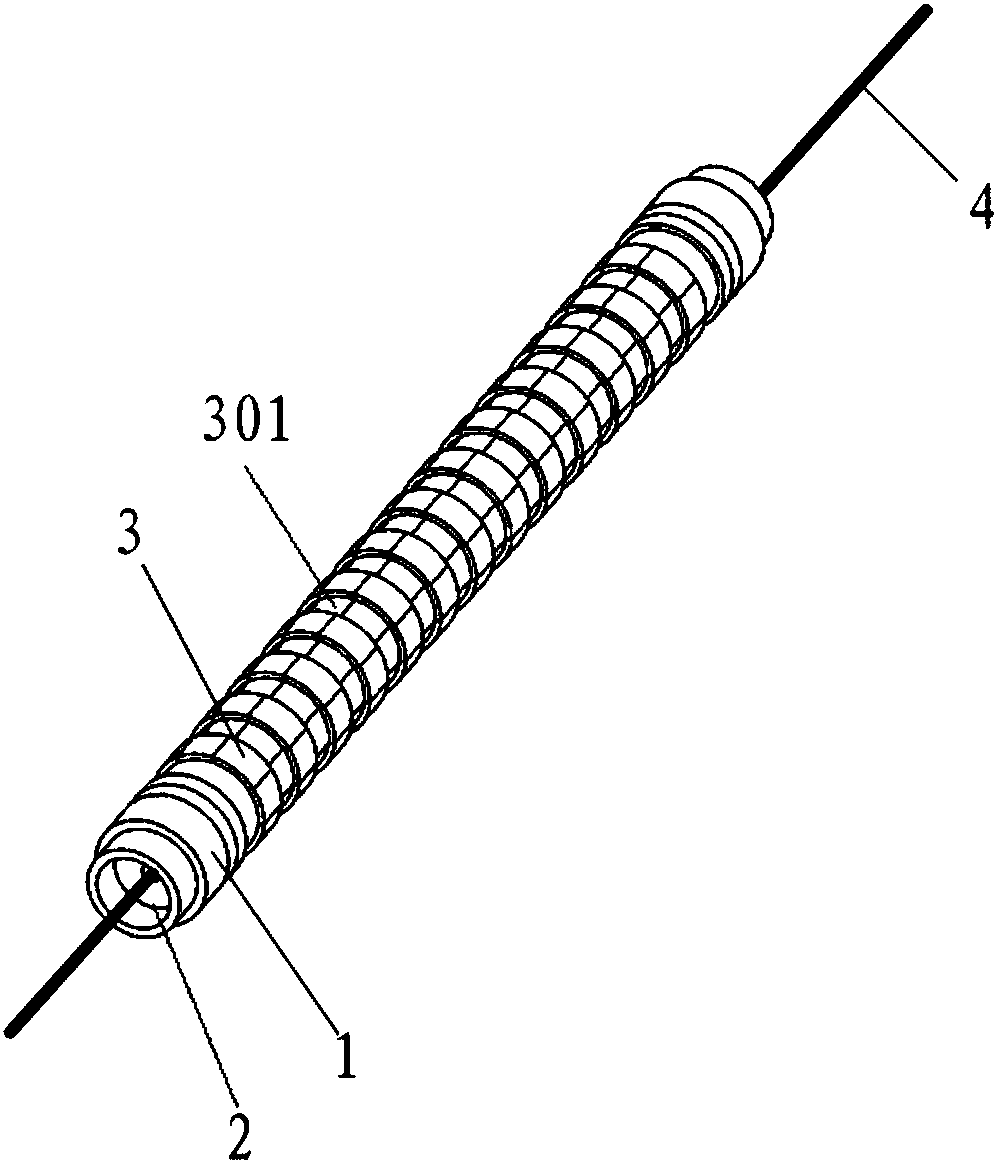

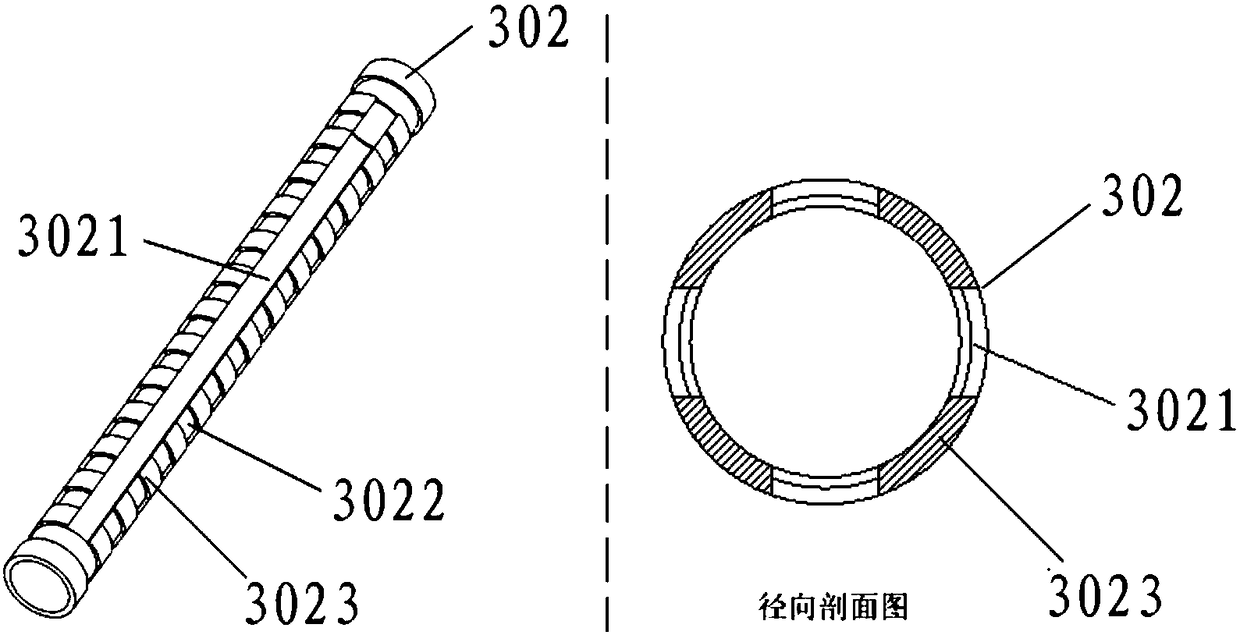

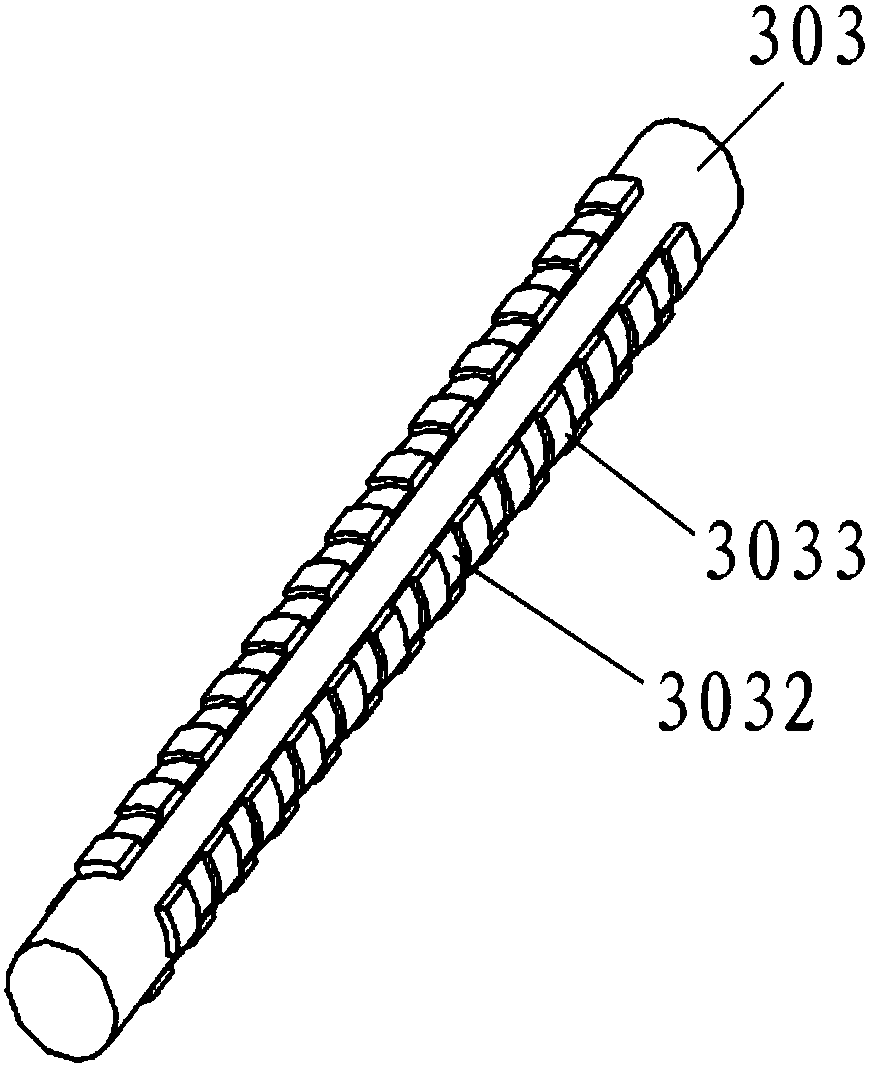

[0049] refer to figure 1 , which shows a schematic diagram of a package structure of a bamboo fiber laser hydrophone in an embodiment of the present invention. In this embodiment, the packaging structure of the bamboo fiber laser hydrophone includes: a pair of end caps 1 , a pair of elastic diaphragms 2 , a bamboo-shaped elastic tube 3 and an active optical fiber 4 .

[0050] In this embodiment, a plurality of circular grooves 301 are provided on the outer surface of the bamboo-shaped elastic cylinder, which is in a tooth-like structure with depressions and protrusions; wherein, the inside of the bamboo-shaped elastic cylinder is filled with silicone oil. A pair of elastic diaphragms are respectively glued to the two ends o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com