Safety interlocking method of continuous wind tunnel cooling system

A technology of safety interlocking and system safety, which is applied in the field of safety interlocking of continuous wind tunnel cooling systems, and can solve the problems of oxygen deficiency of personnel, freezing and cracking of accumulated water in heat exchangers, and excessive vibration of compressors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

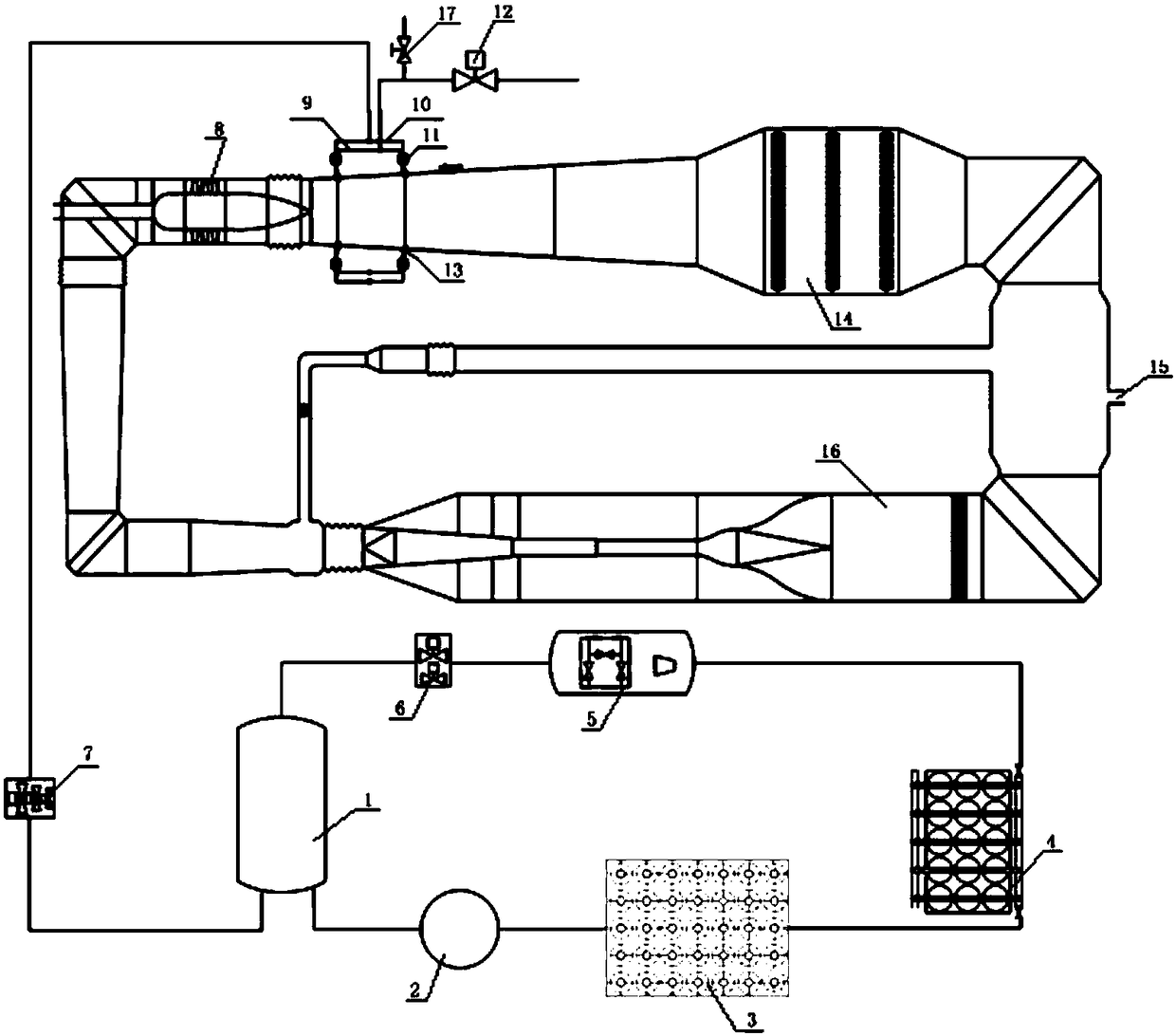

[0101] This embodiment is a safety interlocking method for a continuous wind tunnel cooling system. In order to express clearly, the general structure of the continuous wind tunnel equipped with cooling system is briefly introduced first, and the figure 1 As an example, the liquid nitrogen storage tank 1 in the figure is used for the storage of liquid nitrogen; the liquid nitrogen pump 2 and the vaporizer 3 are used to convert liquid nitrogen into gas nitrogen and store it in the gas cylinder group 4, as a means of pushing liquid nitrogen The driving gas source and the driving gas source of the air control valve; the gas source of the gas cylinder group is adjusted to the required driving gas through the gas distribution table 5; the pushing valve group 6 is placed in the gas distribution table to provide the driving required for squeezing liquid nitrogen gas; the liquid supply valve group 7 is installed in the liquid nitrogen delivery pipeline at the outlet of the liquid nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com