Quick-install fabricated external wall panel

An external wall panel, prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficulty in ensuring project quality, inconvenient disassembly or maintenance, danger of high-altitude operation, etc., and achieves reduction of manual installation time, stable installation effect, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

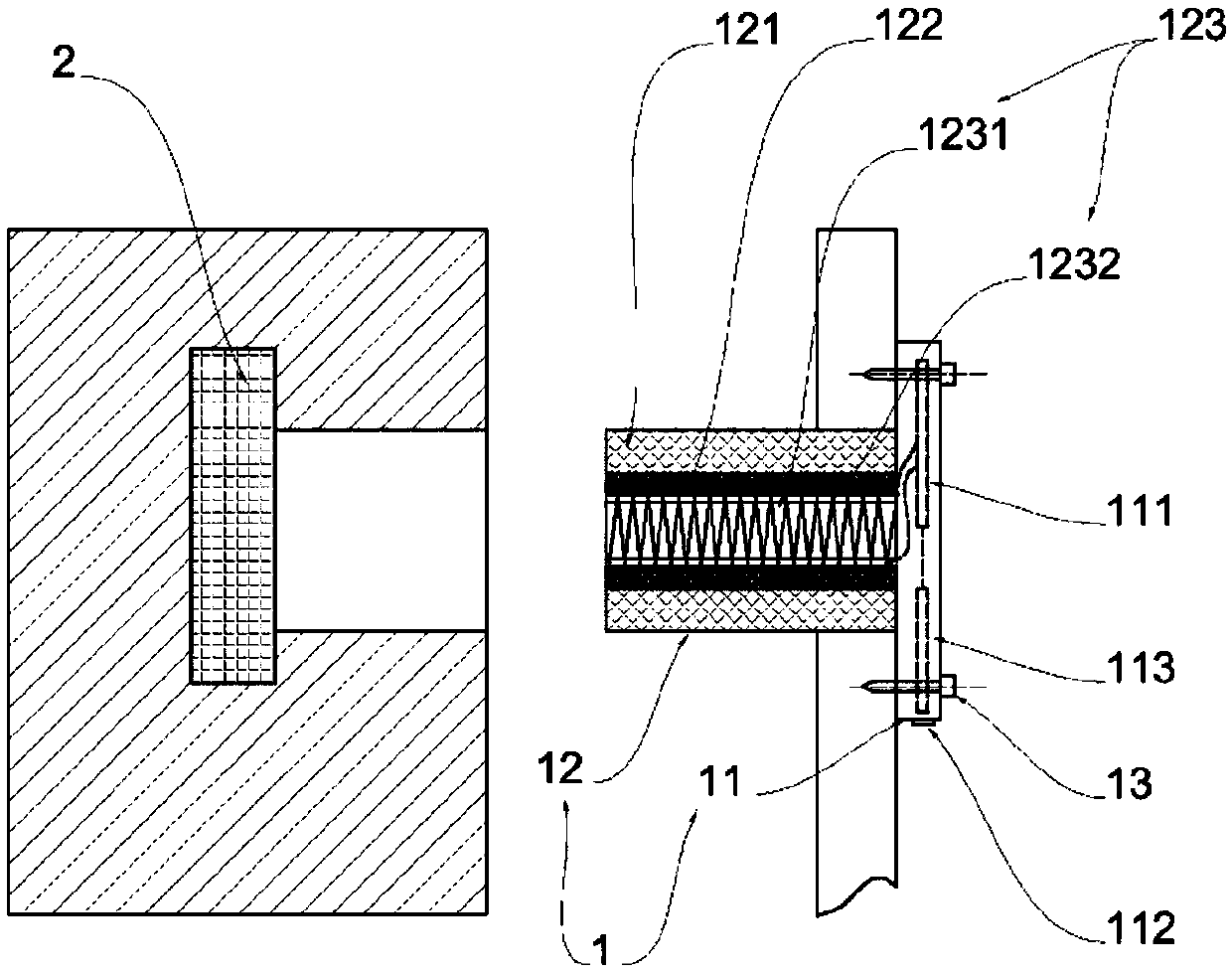

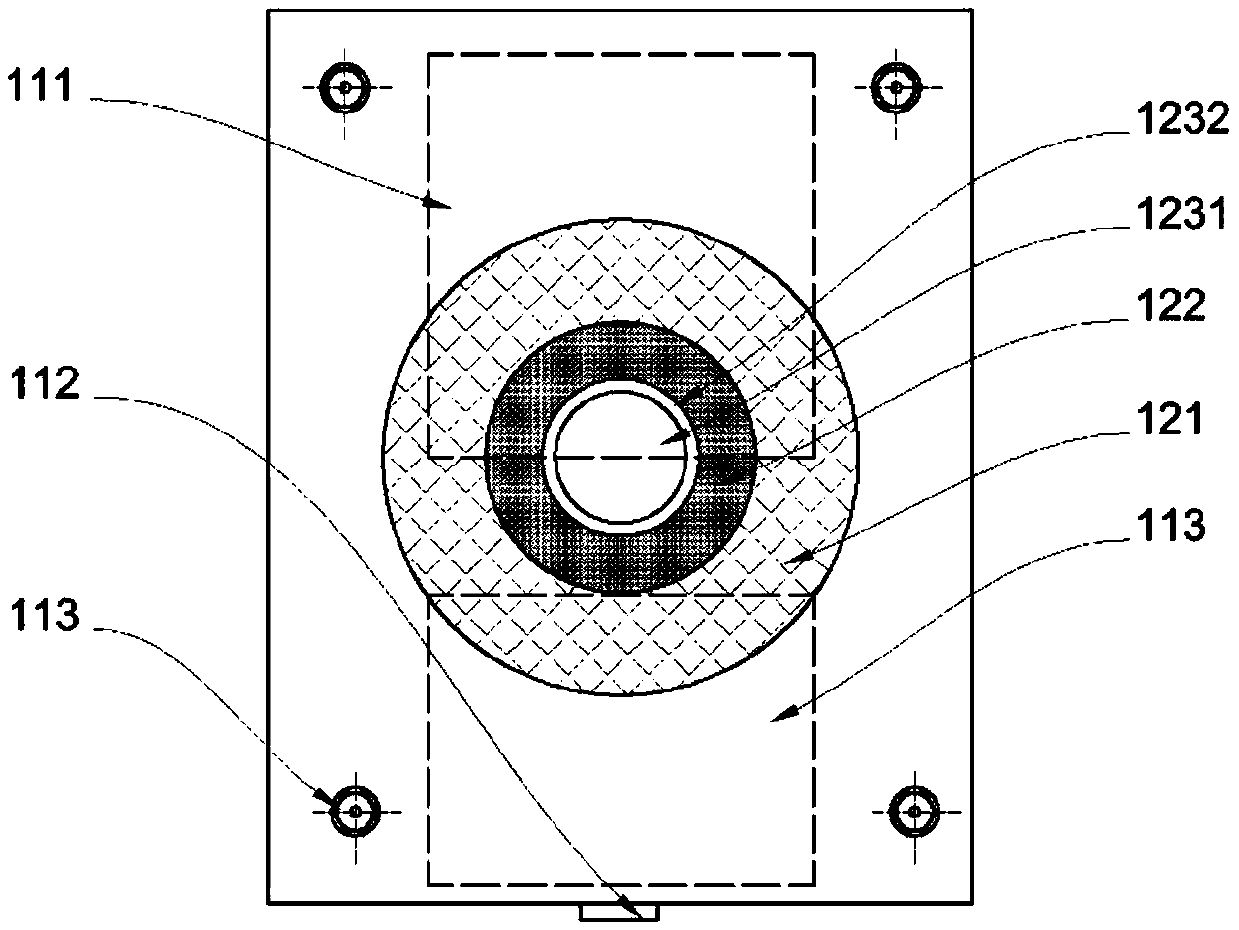

[0028] like figure 1 , figure 2 Shown: a fast-installed assembled exterior wall panel, characterized in that the exterior wall panel is provided with several connecting parts 1 (the number and position of the connecting parts 1 should be flexibly set according to the specific shape of the exterior wall panel , generally should be set at the geometric center or edge, and set symmetrically, subject to the stability of the connection. For example, a circular plate can be set evenly at the center of the circle and at the periphery; a square plate can be set at the corner or the center of the edge.), The connecting part 1 is a "T"-shaped structure composed of a horizontal end 11 and a vertical end 12 (the "horizontal" and "vertical" mentioned in the text of the present invention refer to the positive "T" shape, in the accompanying drawings What is shown is the form when the "T" type is sideways); the vertical end 12 is cylindrical, and from the outside to the inside is a permanen...

Embodiment 2

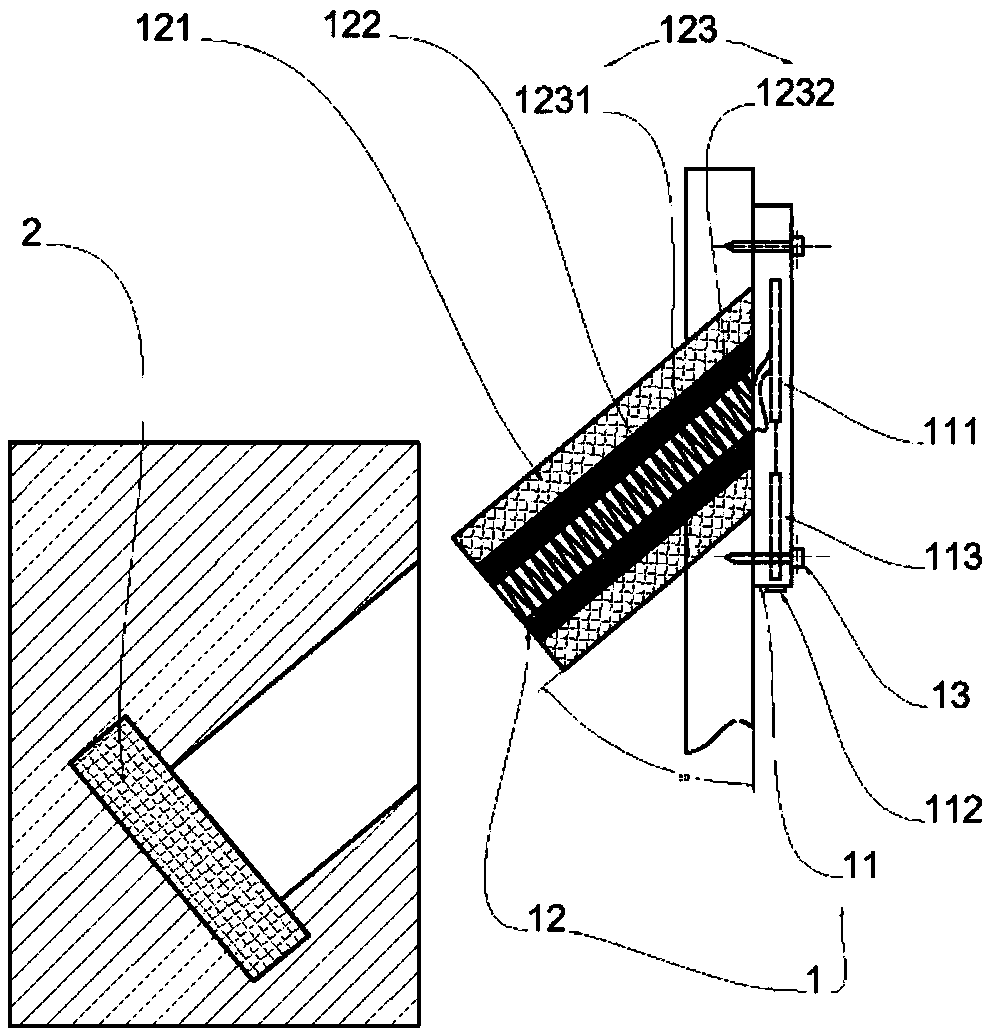

[0039] like image 3 As shown, this embodiment is optimized as follows on the basis of Embodiment 1: the angle between the vertical end 12 and the horizontal end 11 is 50°. Through the angle setting of the horizontal end 11 and the vertical end 12, the external wall panel is hung on the wall base by its own gravity under the action of the connecting part 1, even in the case of a large fire that causes the magnetism of the permanent magnetic layer 121 to weaken, it can still be guaranteed. The stability of the exterior wall panels further improves the safety of the exterior wall panels (if the angle is too large, the hanging effect is not good, and if the angle is too small, it is difficult to install and implement. Under normal circumstances, the angle should be selected at 40°~85°, preferably 42°~ 55°); in the process of dismantling the exterior wall panels, it can avoid the possible falling off of the exterior wall panels due to unstable hoisting after degaussing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com