Quartz vibrating beam accelerometer with self-checking function and manufacturing method and self-checking method thereof

An accelerometer and vibrating beam technology, which is applied in the field of chip bonding and quartz vibrating beam accelerometers, can solve the problems of high contact surface smoothness and flatness, high temperature control requirements, and low long-term stability. The effect of reducing requirements, low process compatibility requirements, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

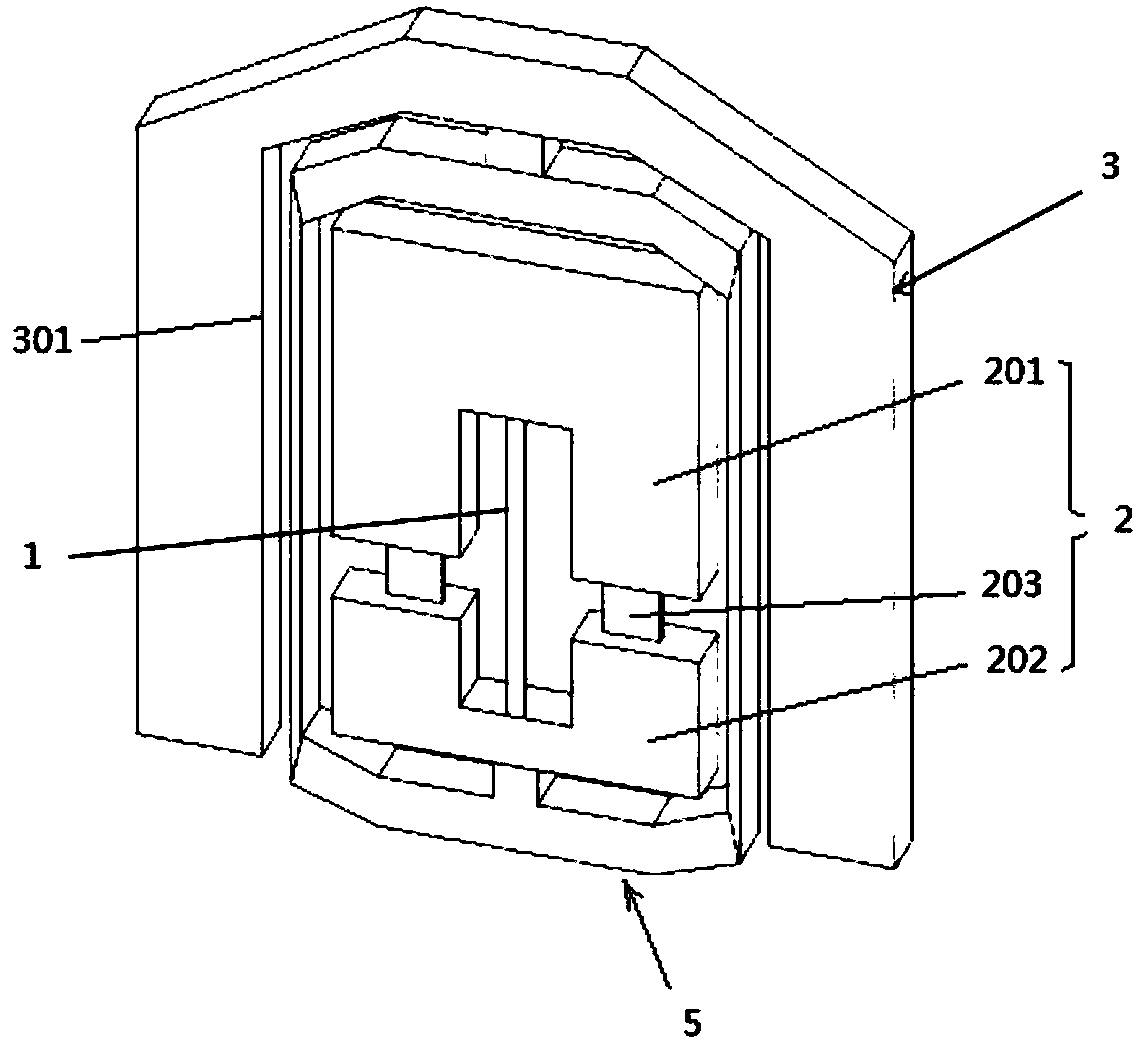

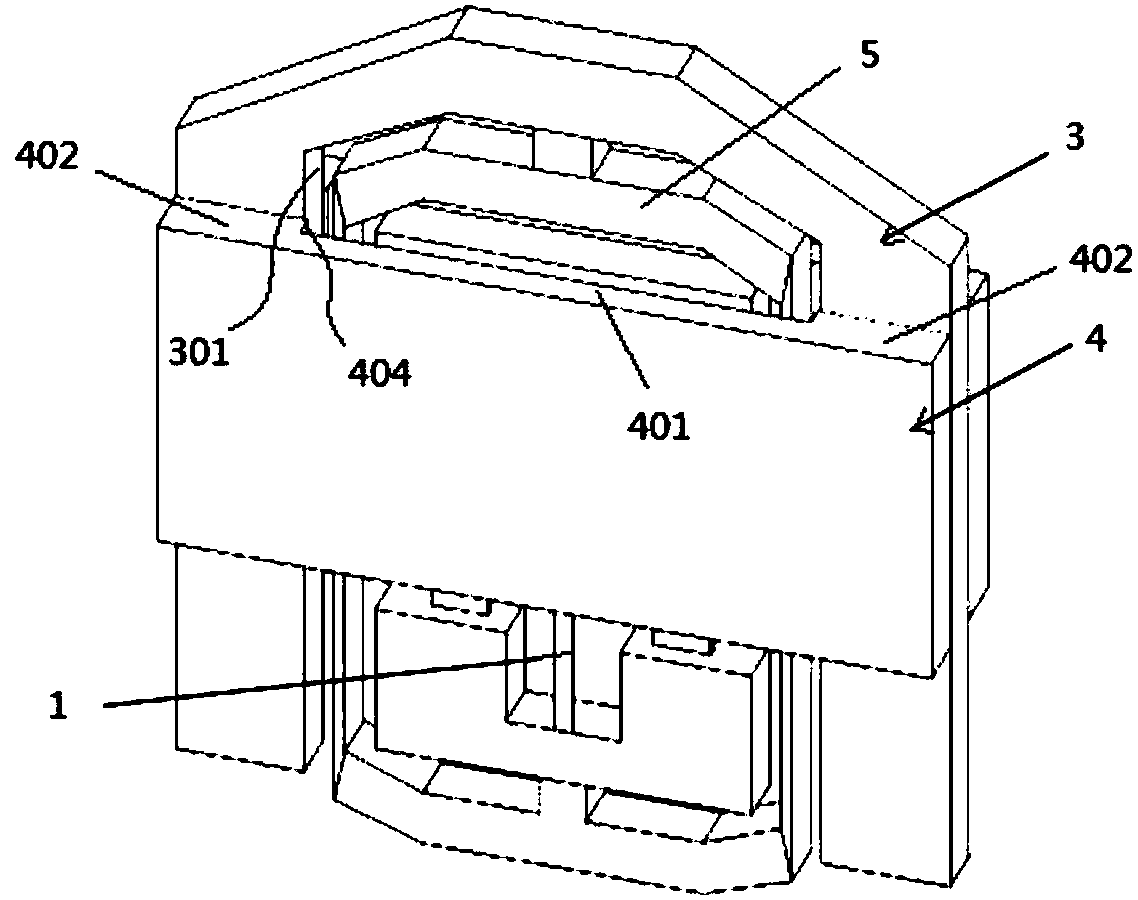

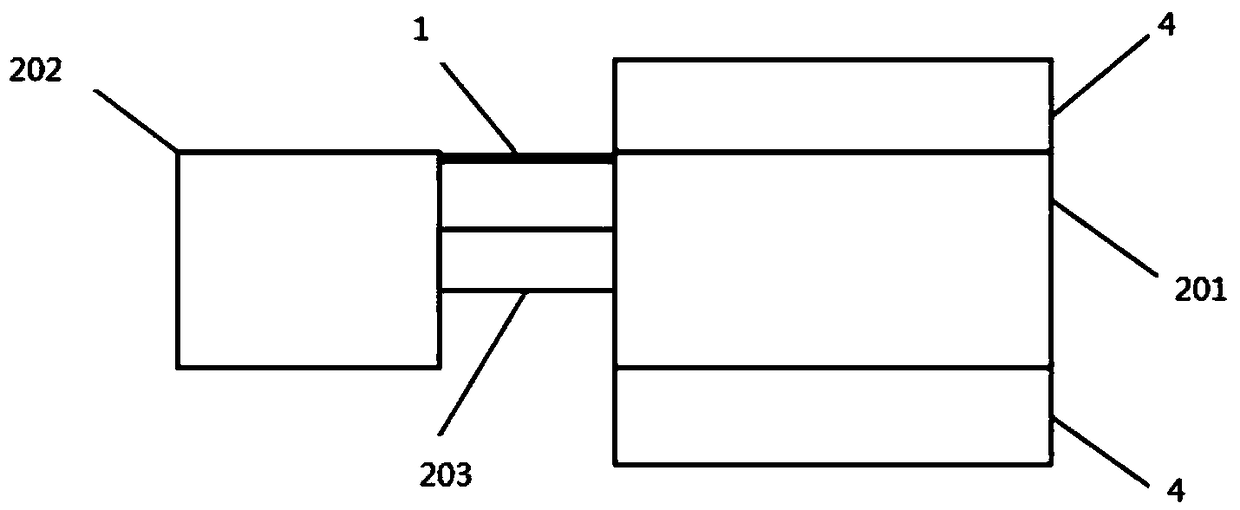

[0024] Such as figure 2 As shown, the quartz beam accelerometer of the present invention includes a quartz beam accelerometer module and a self-check module. The quartz vibrating beam accelerometer module includes a quartz vibrating beam 1 and a quality-flexible structure 2, both of which can be integrated or split, wherein the quality-flexible structure 2 includes a movably connected mass 201 and a base 202, preferably Yes, the mass block 201 and the base 202 are connected by a flexible hinge 203 . In the present invention, the quartz vibrating beam 1 and the mass flexible structure 2 can be but not limited to be arranged in the isolation frame 5 , specifically the base 202 is connected to the isolation frame 5 , and the isolation frame 5 is connected to the installation frame 3 . The self-inspection module is passed above and / or below the mass block 201 (in this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com