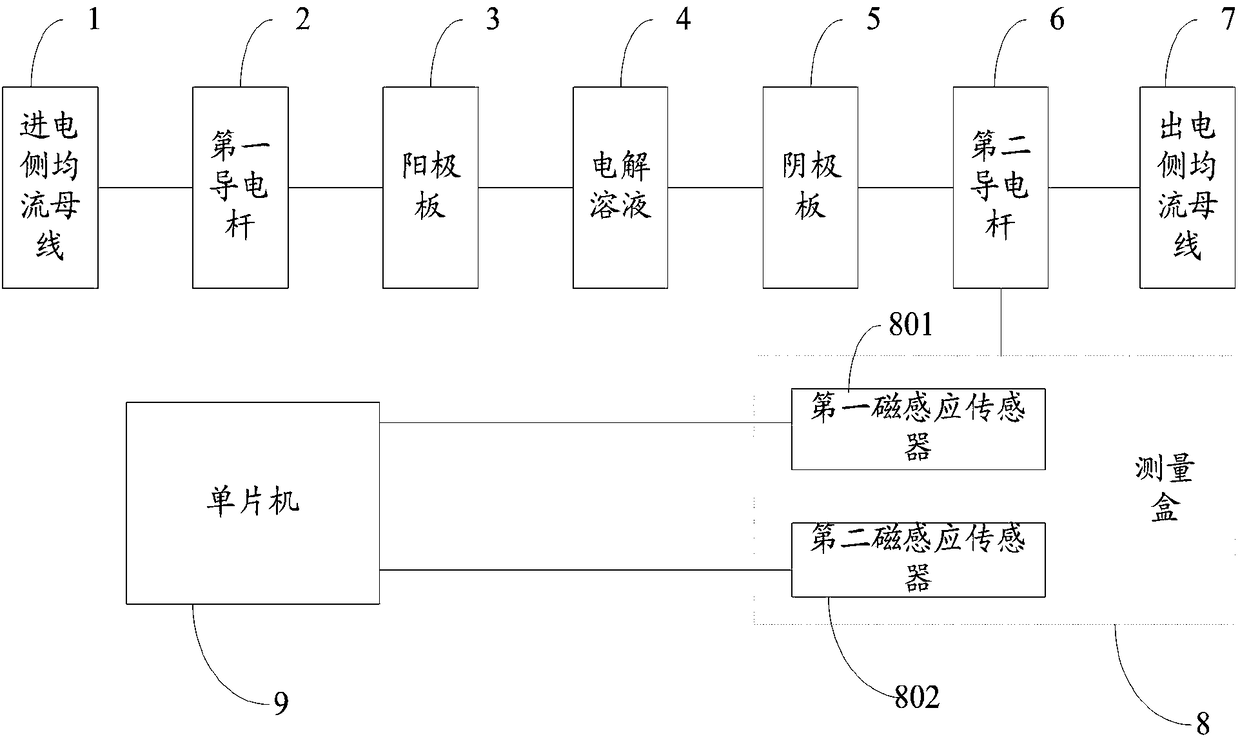

Device and method for determining currents of electrolytic cell cathode plate

A technology for determining devices and electrolyzers, applied to measuring devices, measuring only current, measuring current/voltage, etc., can solve the problem of large current error of the cathode plate and achieve the effect of reducing measurement error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

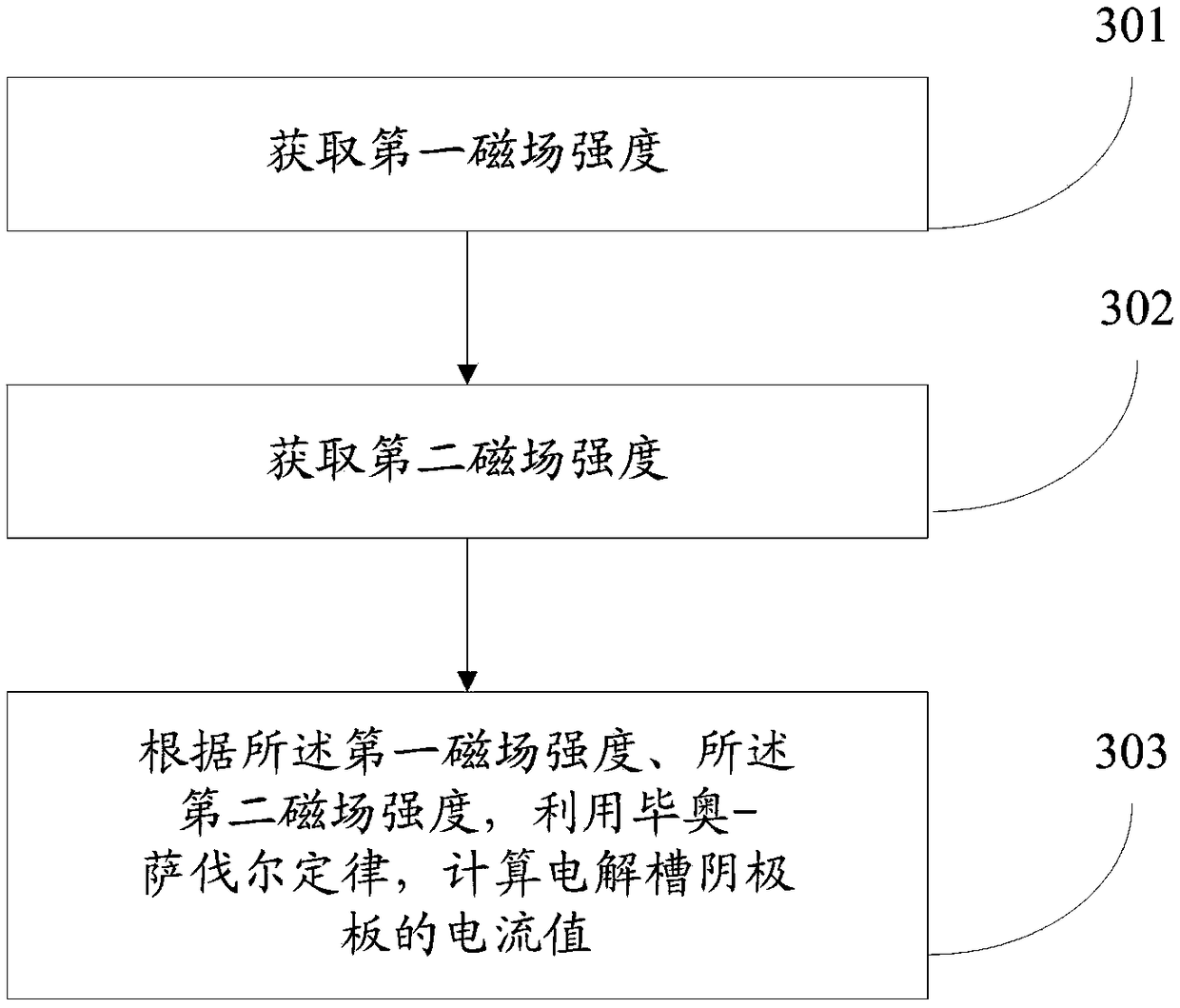

Method used

Image

Examples

specific Embodiment approach 1

[0046] Specific implementation mode one: measurement of cathode current in copper electrolytic refining

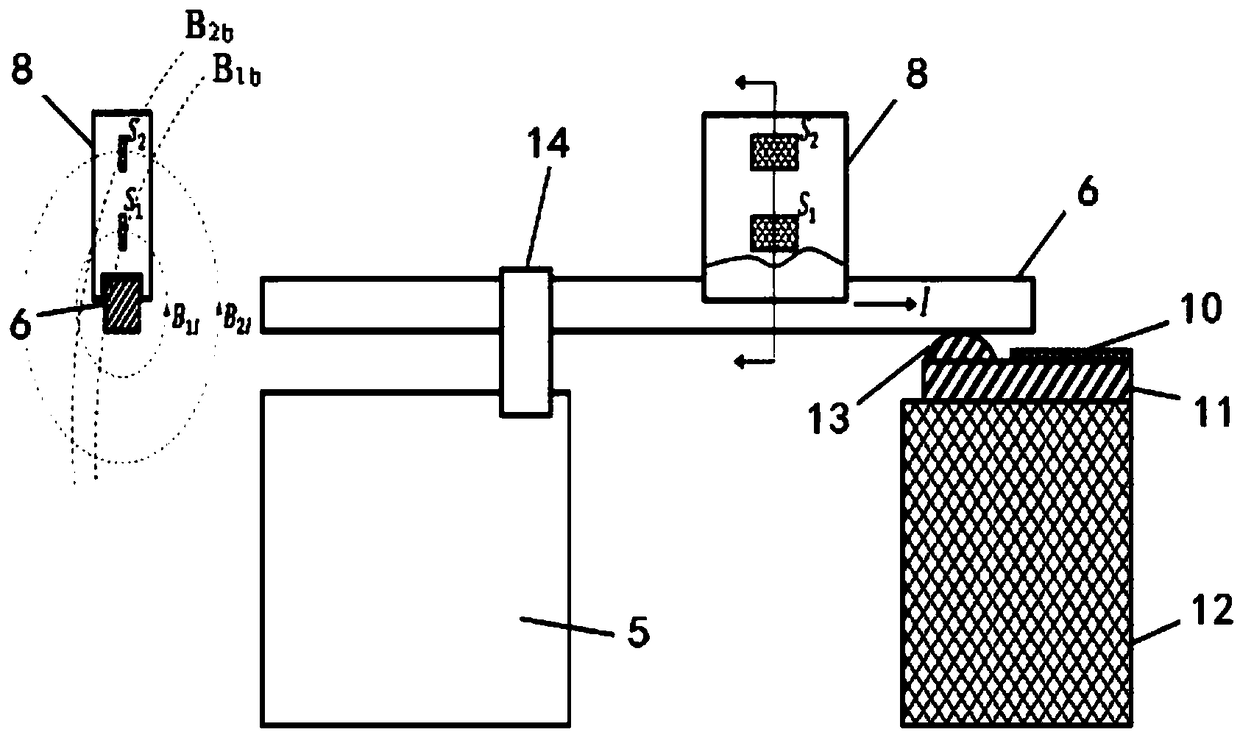

[0047] Such as figure 2 As shown, the measurement box 8 is a measurement box 8 with two Hall elements built in. A concave groove with a surplus width of 30 mm is processed at the bottom of the measurement box 8, and the Hall elements S1 and S2 for measuring the magnetic field are respectively fixed at a height of 10 mm and 30 mm from the bottom surface of the groove, and the working surfaces of the Hall elements S1 and S2 are parallel to the second The center line of the conductive rod 6 ensures that the magnetic field lines of the magnetic field generated by the current of the second conductive rod 6 pass through the working surfaces of the Hall elements S1 and S2 vertically. Use a controllable current power supply to determine the calibration constant k on a conductive rod with the same conductive structure layout. Clamp the measuring box 8 in the middle of the second...

specific Embodiment approach 2

[0049] Specific implementation mode two: measurement of nickel electrolysis cathode current

[0050] Such as figure 2 As shown, the measurement box 8 is a measurement box 8 with two Hall elements built in. A circular concave groove with a diameter of 20 mm is machined at the bottom of the measurement box 8, and the Hall elements S1 and S2 for measuring the magnetic field are respectively fixed at a height of 10 mm and 30 mm from the bottom surface of the groove, and the working surfaces of the Hall elements S1 and S2 are parallel to The center line of the second conductive rod 6 ensures that the magnetic field lines of the magnetic field generated by the current of the second conductive rod 6 pass through the working surfaces of the Hall elements S1 and S2 vertically. Use a controllable current power supply to determine the calibration constant k on a conductive rod with the same conductive structure layout. Clamp the measuring box 8 in the middle of the second conductive r...

specific Embodiment approach 3

[0051] Specific implementation mode three: measurement of zinc electrolysis cathode current

[0052] Such as figure 2 As shown, the measurement box 8 is a measurement box 8 with two Hall elements built in. A rectangular concave groove with a diameter of 20 mm is machined at the bottom of the measuring box 8, and the Hall elements S1 and S2 for measuring the magnetic field are respectively fixed at a height of 10 mm and 30 mm from the bottom surface of the groove, and the working surfaces of the Hall elements S1 and S2 are parallel to the first The center line of the two conductive rods 6 ensures that the magnetic field lines generated by the current of the second conductive rod 6 pass through the working surfaces of the Hall elements S1 and S2 vertically. Use a controllable current power supply to determine the calibration constant k on a conductive rod with the same conductive structure layout. Clamp the measuring box 8 in the middle of the second conductive rod 6, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com