Hot straightening machine intelligent model system and control method thereof

A model system and heat straightening technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of unsatisfactory use effect of the model control system of the hot straightening machine, so as to facilitate tracking and management, and stabilize product quality , easy to manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

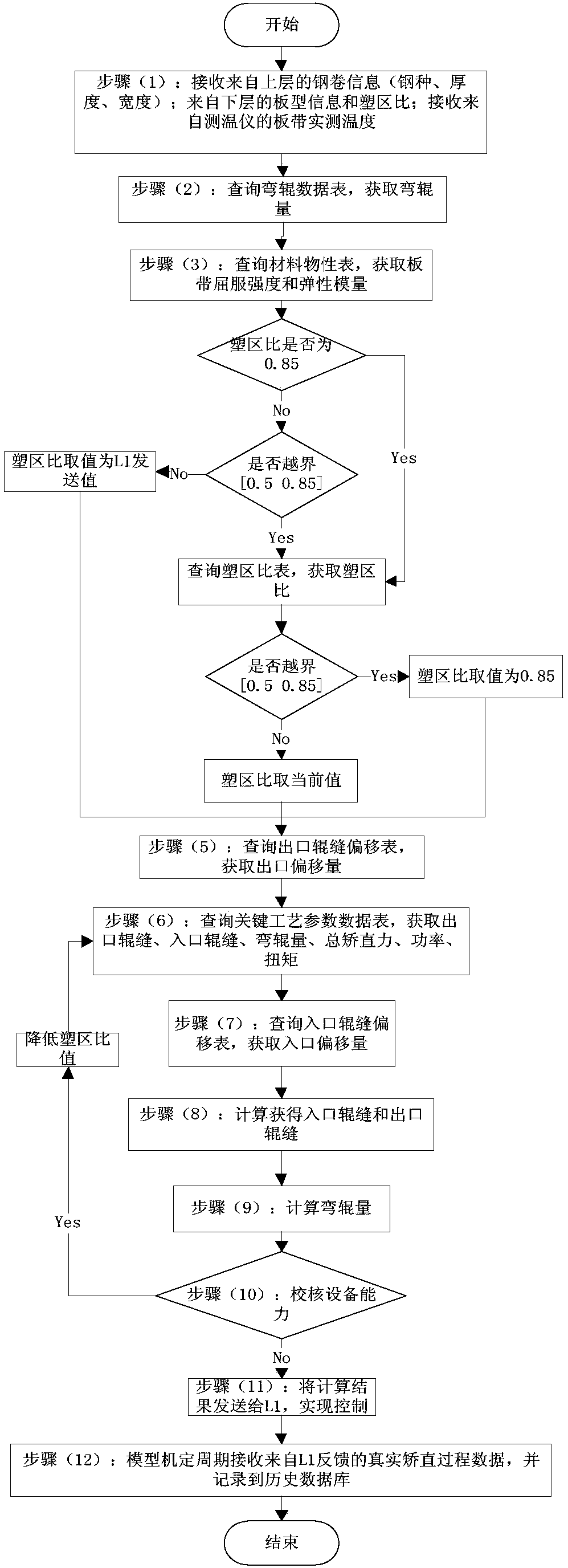

[0028] In order to make the content and advantages of the technical solution of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

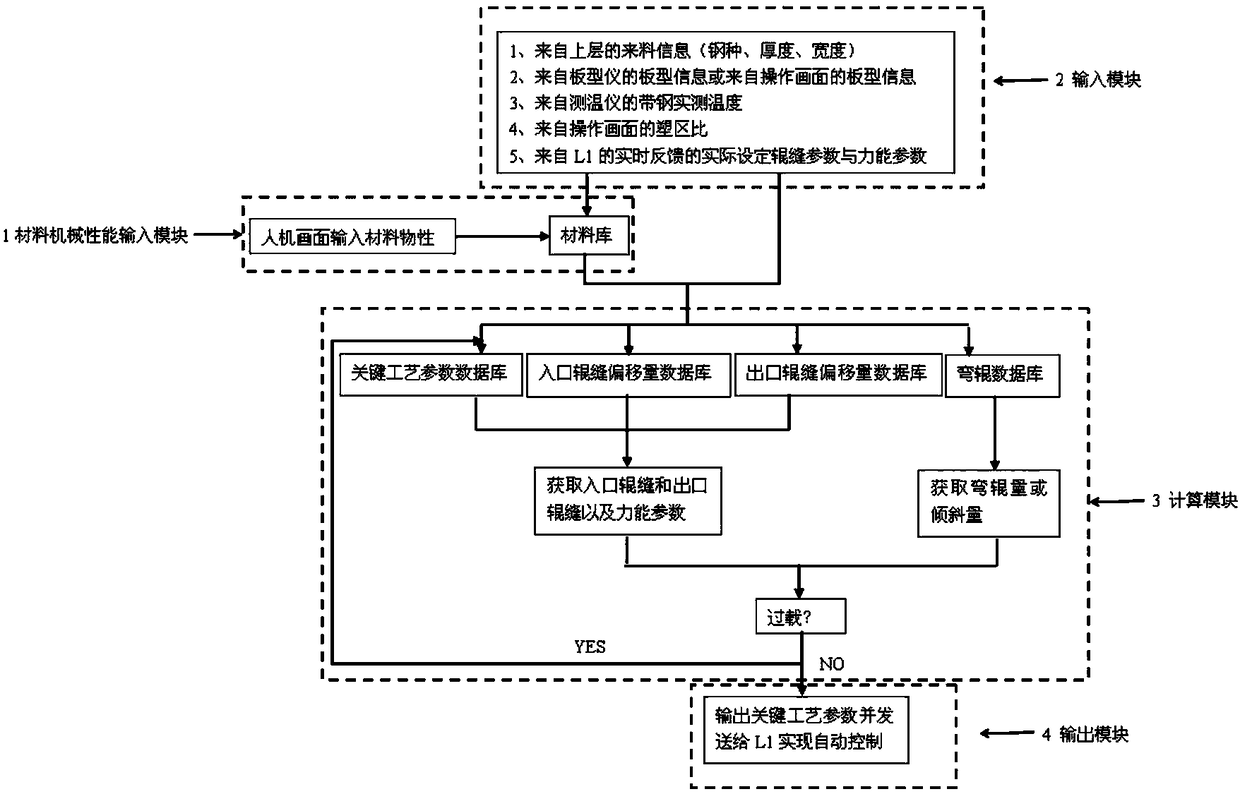

[0029] combine figure 1 A structural block diagram of an intelligent model system for a thermal straightening machine. The model system includes the following modules: 1. a material mechanical property input module, 2. a model system input module, 3. a model system calculation module, and 4. a model system output module.

[0030] 1. Material mechanical property input module. The material mechanical property input module inputs the corresponding yield strength and elastic modulus of various steel types at different temperatures to the material library through the material mechanical property man-machine input interface, and the material library calculates through the signal line and the model system The modules are connected. Material yield strength and elastic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com