Lithium titanate material, preparation and application thereof

A technology of lithium titanate and said lithium titanate, applied in the field of electrochemical energy storage, can solve problems such as battery performance decline, and achieve the effect of inhibiting flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

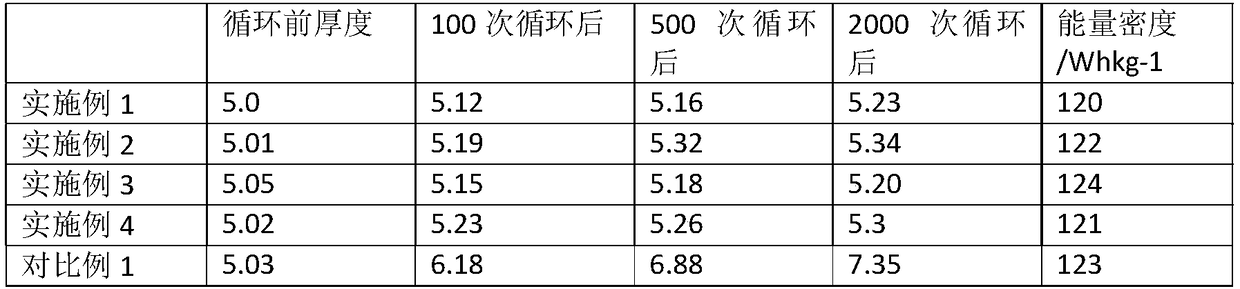

Examples

Embodiment 1

[0018] Put 10g of lithium titanate powder with a particle size of 10 microns and 5g of fluorinated graphene into 100ml of absolute ethanol, ultrasonically disperse for 10 hours, centrifuge, remove the supernatant, and vacuum-dry the precipitate at 100 degrees to obtain fluorine-containing Lithium titanate material of graphene.

Embodiment 2

[0020] Put 10g of lithium titanate powder with a particle size of 20 microns and 4g of fluorinated graphite into 100ml of acetone, ultrasonically disperse for 12 hours, centrifuge, remove the supernatant, and vacuum-dry the precipitate at 80 degrees to obtain fluorinated graphene lithium titanate material.

Embodiment 3

[0022] Put 10g of lithium titanate powder with a particle size of 50 microns and 5g of fluorinated graphene into 100ml of absolute ethanol, ultrasonically disperse for 10 hours, centrifuge, remove the supernatant, and vacuum-dry the precipitate at 100 degrees to obtain fluorine-containing Lithium titanate material of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com