Using ferrous gluconate as a single raw material to prepare ferric oxide/graphene oxide-like magnetic nanocomposites

A technology of ferrous gluconate and ferric tetroxide, applied in the field of nanomaterials, can solve the problems of complex preparation process, difficult to strictly control conditions, difficult to obtain purity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

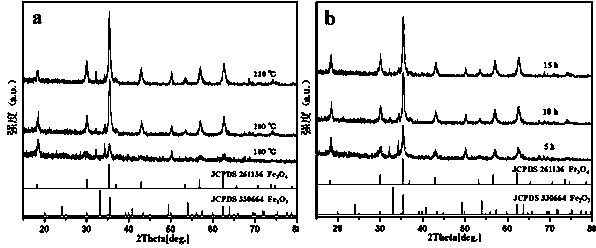

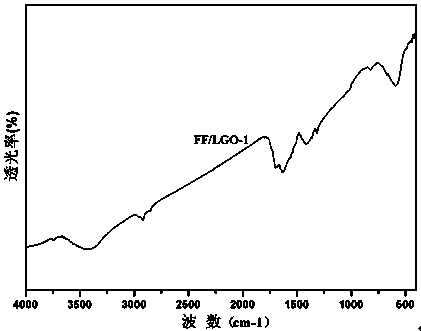

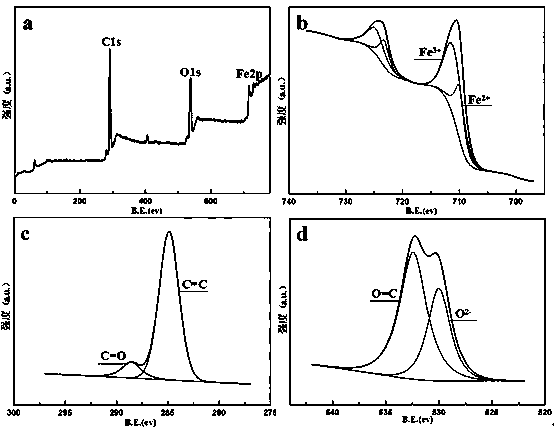

[0045] 1.9291 g Fe(OOC(CHOH) 4 CH 2 OH) 2 ·2H 2 O (with Fe 2+ Expressed as 0.0833 mol / L) added to 48.00 mL H 2 After stirring and dissolving in O, transfer to a polytetrafluoroethylene reactor and react at 200 ℃ for 10 h. After the reaction, the solid product was washed with absolute ethanol and secondary water, then placed in an oven and dried at 90-100 ℃ for 9-11h to obtain composite FF / LGO-1.

[0046] A certain amount of this material was soaked in a 6 mol / L HCl solution for 24 hours, and the Fe in the composite material was calculated according to the mass change before and after soaking. 3 O 4 The actual compounding amount is 41.2%. The magnetization of the composite material is 68.8 emu / g.

Embodiment 2

[0048] Fe(OOC(CHOH) 4 CH 2 OH) 2 ·2H 2 The added amount of O is 2.8933 g (with Fe 2+ The molar concentration of is expressed as 0.1250 mol / L), and other conditions are the same as in Example 1, the obtained composite material FF / LGO-2. Fe in the composite 3 O 4 The actual compounding amount is 41.0%; its magnetization is 58.2 emu / g.

Embodiment 3

[0050] Fe(OOC(CHOH) 4 CH 2 OH) 2 ·2H 2 The added amount of O is 3.8575 g (with Fe 2+ The molar concentration of is expressed as 0.1667 mol / L), and other conditions are the same as in Example 1, the obtained composite material FF / LGO-3.

[0051] Fe in the composite 3 O 4 The actual compounding amount is 40.6%; its magnetization is 50.3 emu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com