Preparation method of self-adhesive polymer/disperse dye composite particles and its application in hot-melt dyeing of polyester

A technology of disperse dyes and composite particles, which is applied in dyeing methods, textiles and papermaking, etc. It can solve the problems of low transfer efficiency, difficulty in processing polyester hot-melt dyeing, and weak force, and achieve increased interaction strength and good dyeing effect , the effect of enhancing the interaction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 2.3g of Disperse Red 307 filter cake, 1.2g of sodium lignosulfonate, 0.2g of polyoxyethylene polyoxypropylene pentaerythritol ether and 50g of water, mix and add to a horizontal sand mill (SWS series, Shanghai Shihe Electromechanical Co., Ltd. Equipment Co., Ltd.) for grinding. 0.8 mm zirconia beads were used for grinding, the pump speed was 500 rpm, and the grinding was performed for 10 hours to obtain an aqueous dispersion of disperse dye particles.

[0051] The Z-average particle diameter of the disperse dye particles measured by a Nano-ZS90 Zetasizer dynamic light scattering nanoparticle size analyzer is 225nm.

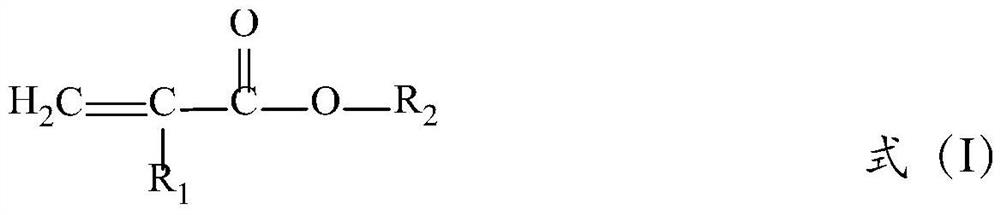

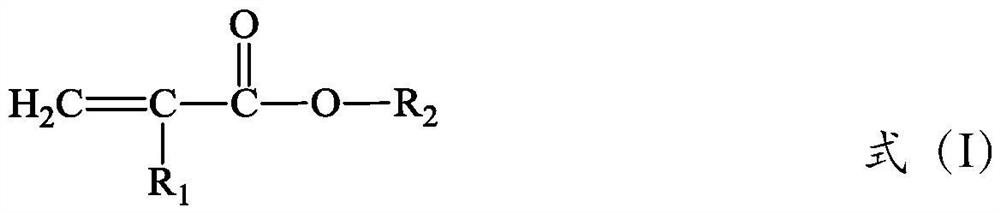

[0052] Dissolve 0.2g of Tween-20 and 1.2g of sodium lignosulfonate in 50g of water to obtain an aqueous phase solution; weigh 7.9g of isooctyl acrylate, 3.7g of styrene, and 0.9g of methacrylic acid-2-hydroxyethyl ester, 0.9 g of glycidyl acrylate, 0.9 g of n-hexadecane and 0.17 g of azobisisobutyronitrile to obtain an oil phase solution. After mixi...

Embodiment 2

[0058] Weigh 4.4g of Disperse Yellow 211 filter cake, 3.0g of hydroxypropyl cellulose, 0.2g of polyoxyethylene polyoxypropanolamine ether and 60g of water, mix and add to a horizontal sand mill (SWS series, Shanghai Siehe Electromechanical Equipment Co., Ltd.) for grinding. 0.8 mm zirconia beads were used for grinding, the pump speed was 400 rpm, and the grinding was performed for 12 hours to obtain an aqueous dispersion of disperse dye particles.

[0059] The Z-average particle diameter of the disperse dye particles measured by a Nano-ZS90 Zetasizer dynamic light scattering nanoparticle size analyzer is 370nm.

[0060] Dissolve 0.6g MOA-9 and 3.0g hydroxypropyl cellulose in 60g water to obtain an aqueous phase solution; weigh 6.9g isooctyl acrylate, 6g methyl methacrylate, 4.1g vinyl acetate, 2.5g formazan 2-hydroxyethyl acrylate, 0.5 g of glycidyl methacrylate, 0.7 g of n-hexadecane and 0.33 g of azobisisoheptanonitrile were mixed to obtain an oil phase solution. After mix...

Embodiment 3

[0066] Weigh 5.9g of Disperse Blue 337 filter cake, 4.5g of polyacrylic acid, 0.2g of polyoxypropylene glyceryl ether and 55g of water, mix them and add them to a horizontal sand mill (SWS series, Shanghai Shihe Electromechanical Equipment Co., Ltd.) grind. 1.3 mm zirconia beads were used for grinding, the pump speed was 600 rpm, and the grinding was performed for 15 hours to obtain an aqueous dispersion of disperse dye particles.

[0067] The Z-average particle diameter of the disperse dye particles measured by a Nano-ZS90 Zetasizer dynamic light scattering nanoparticle size analyzer is 385nm.

[0068] Dissolve 1.3g of dodecyl dimethyl sulfopropyl betaine and 4.5g of polyacrylic acid in 55g of water to obtain an aqueous phase solution; weigh 8.7g of methyl methacrylate, 4.3g of methyl acrylate, 12.1g of Butyl acrylate, 3.7 g of 2-hydroxyethyl methacrylate, 1.6 g of glycidyl acrylate and 1.3 g of n-hexadecane were mixed to obtain an oil phase solution. After mixing the aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com