Ventilated electric motor

A ventilated, machine-based technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of large air friction loss and high-frequency eddy current loss, noise-generating main motor, and ineffective effect, etc. Large channel space, preventing rotor friction and damage, and smooth ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

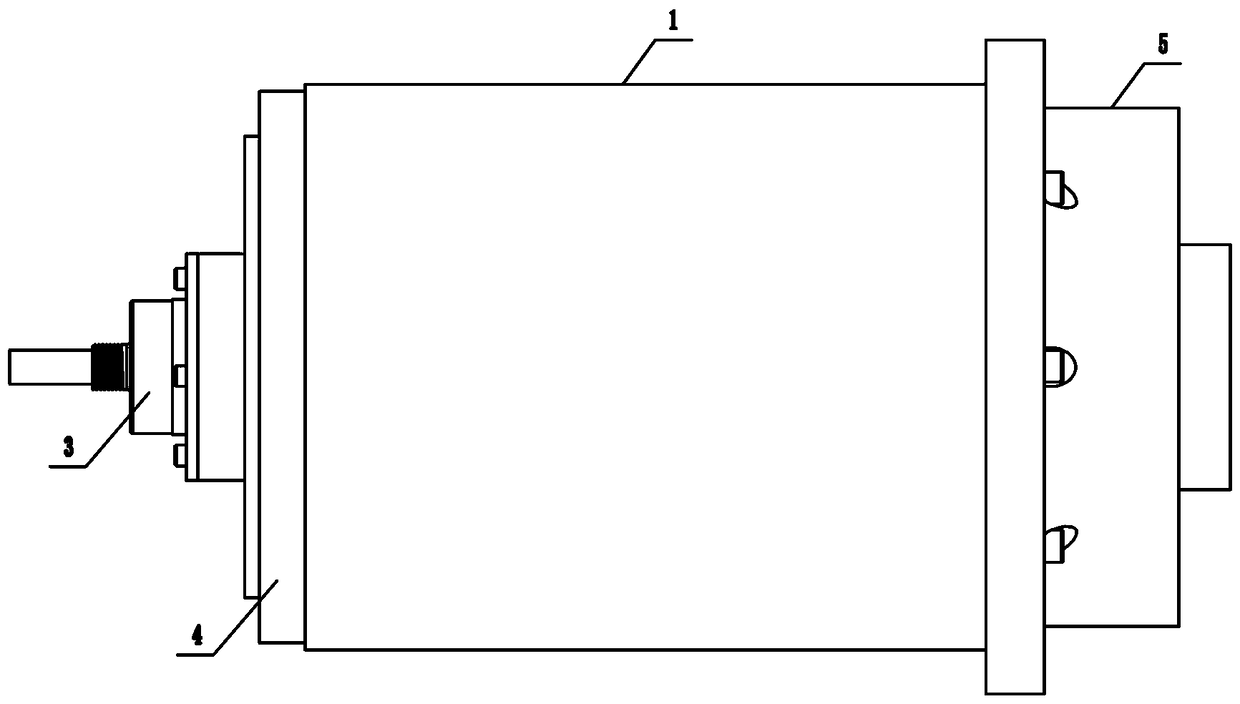

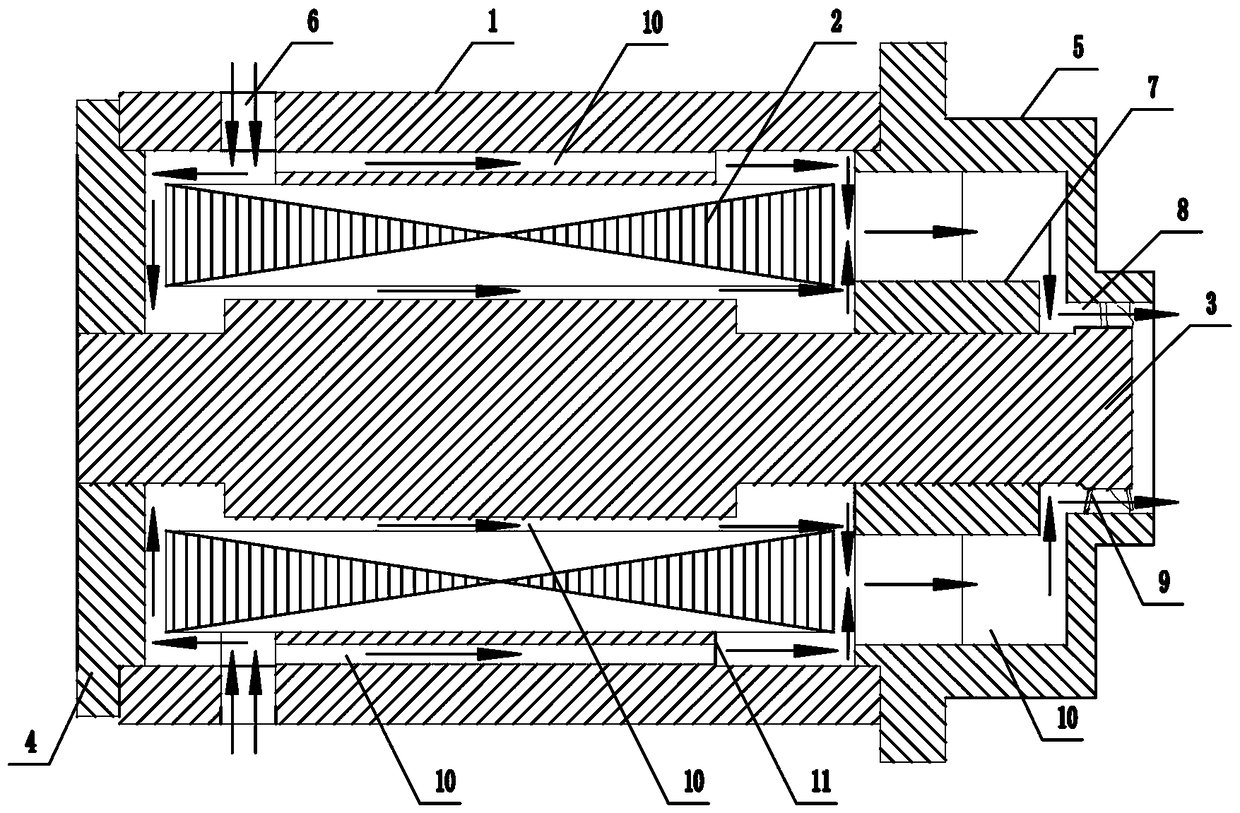

[0036] like figure 1 and figure 2 As shown, the present invention includes a machine base 1, a stator 2, and a rotor 3. The two ends of the machine base 1 are fixedly connected to the front end cover 4 and the rear end cover 5 by bolts respectively, and the position of the machine base 1 near the front end cover 4 is provided with multiple The first air inlet 6 (only two of the upper end and the lower end are shown in the figure), the rear end cover 5 is fixedly connected with the positioning sleeve 7, the center of the rear end cover 5 is provided with an air outlet 8, and the rotor 3 One end passes through the positioning sleeve 7 and fixes the fan 9 coaxially. The fan 9 is located in the air outlet 8. An air duct 10 is arranged between the stator 2 and the machine base 1, the front end cover 4, the rear end cover 5 and the rotor 3. , the inner side of the base 1 is provided with a connecting part 11, the outer wall of the stator 2 is in close contact with the connecting p...

Embodiment 2

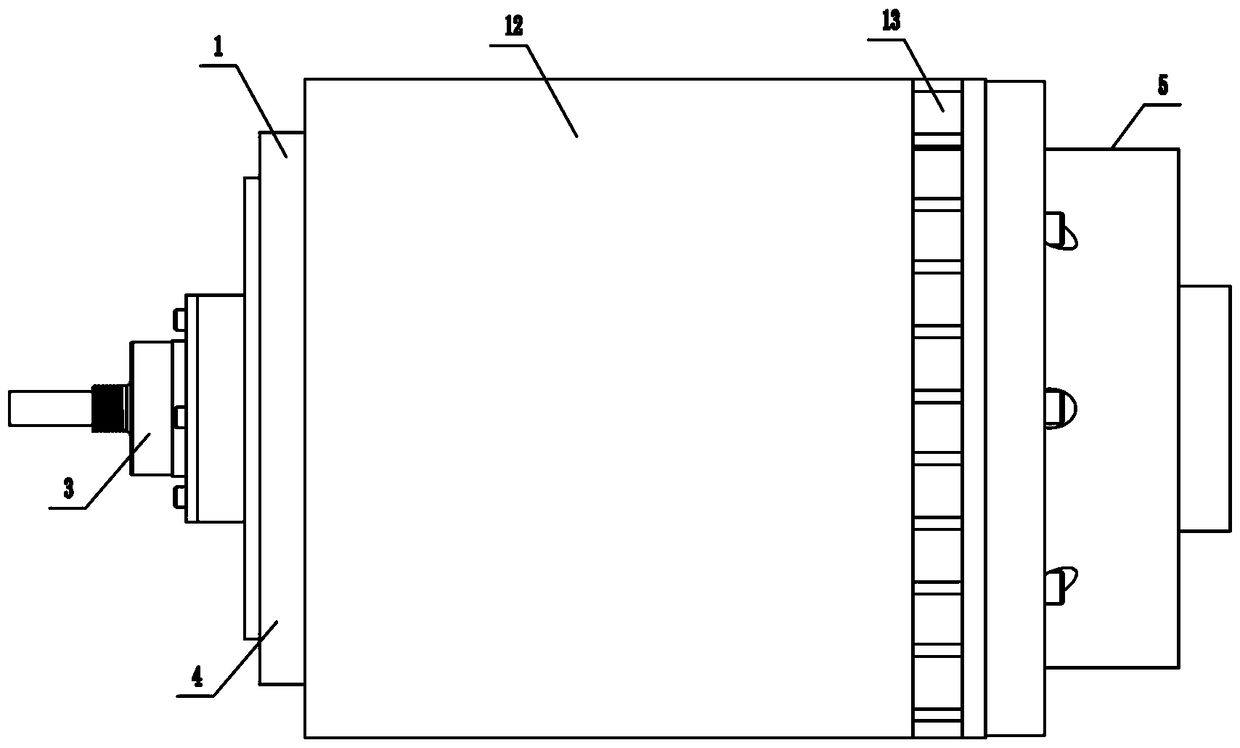

[0038] like image 3 and Figure 4As shown, the present invention includes a machine base 1, a stator 2, and a rotor 3. The two ends of the machine base 1 are fixedly connected to the front end cover 4 and the rear end cover 5 by bolts respectively, and the position of the machine base 1 near the front end cover 4 is provided with multiple The first air inlet 6 (only two of the upper end and the lower end are shown in the figure), the rear end cover 5 is fixedly connected with the positioning sleeve 7, the center of the rear end cover 5 is provided with an air outlet 8, and the rotor 3 One end passes through the positioning sleeve 7 and fixes the fan 9 coaxially. The fan 9 is located in the air outlet 8. An air duct 10 is arranged between the stator 2 and the machine base 1, the front end cover 4, the rear end cover 5 and the rotor 3. , the inner side of the base 1 is provided with a connecting part 11, the outer wall of the stator 2 is in close contact with the connecting pa...

Embodiment 3

[0041] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is: as Figure 5 and Image 6 As shown, a plurality of connecting ribs 15 are arranged between the positioning shaft sleeve 7 and the rear end cover 5, and the connecting ribs 15 are structures with thinner sides and a thicker middle; Under the premise, the structure of the connecting rib is improved, and the connecting rib is designed to be thin on both sides and thick in the middle, such as Figure 4 The shuttle-like structure shown can effectively reduce the wind resistance of the connecting ribs and speed up the air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com