Automatic feed processing and granulating device

A feed processing and material technology, which is applied in the field of automatic feed processing and granulation devices, can solve the problems of poor feed crushing effect, material waste, uneven material forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

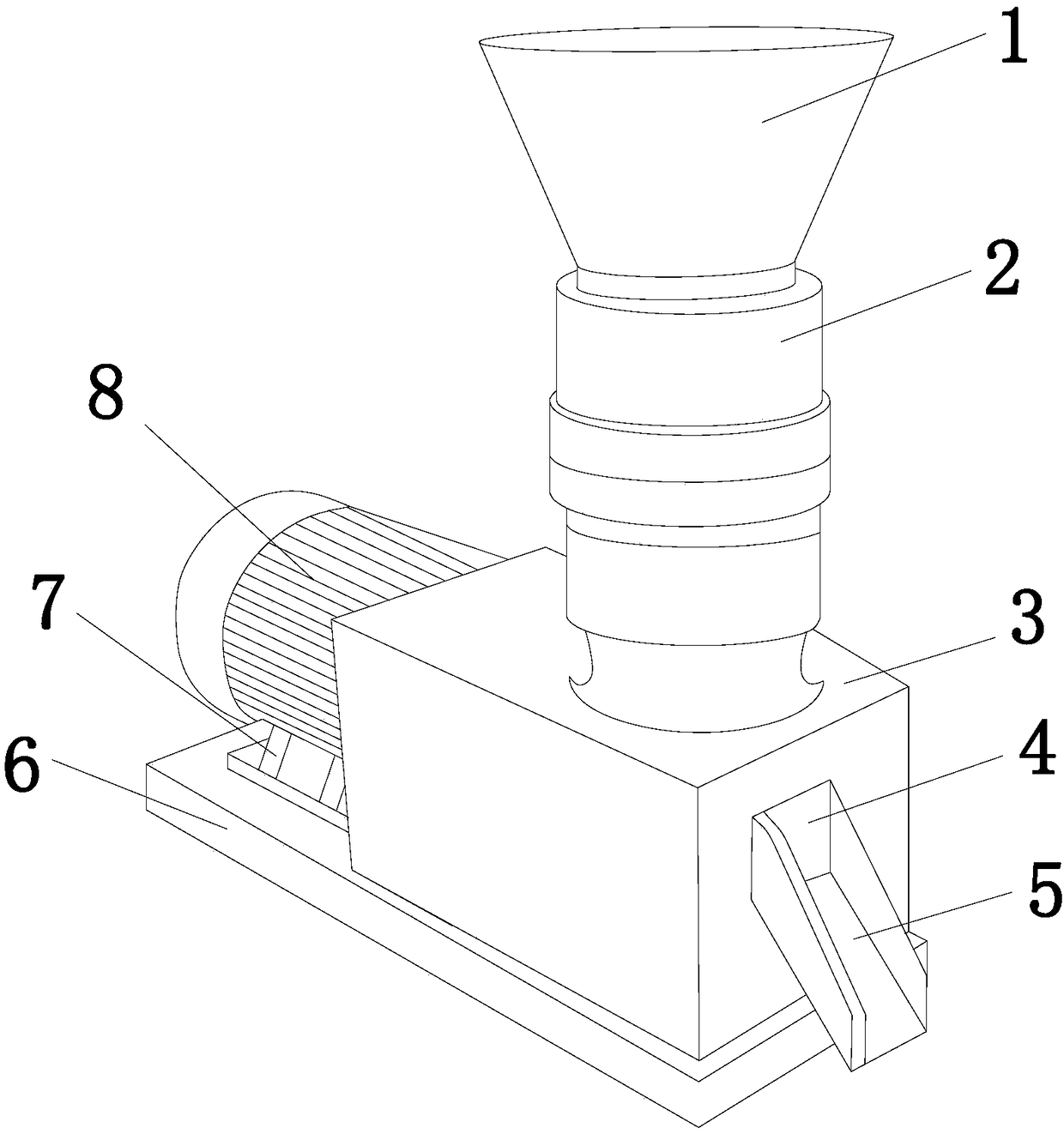

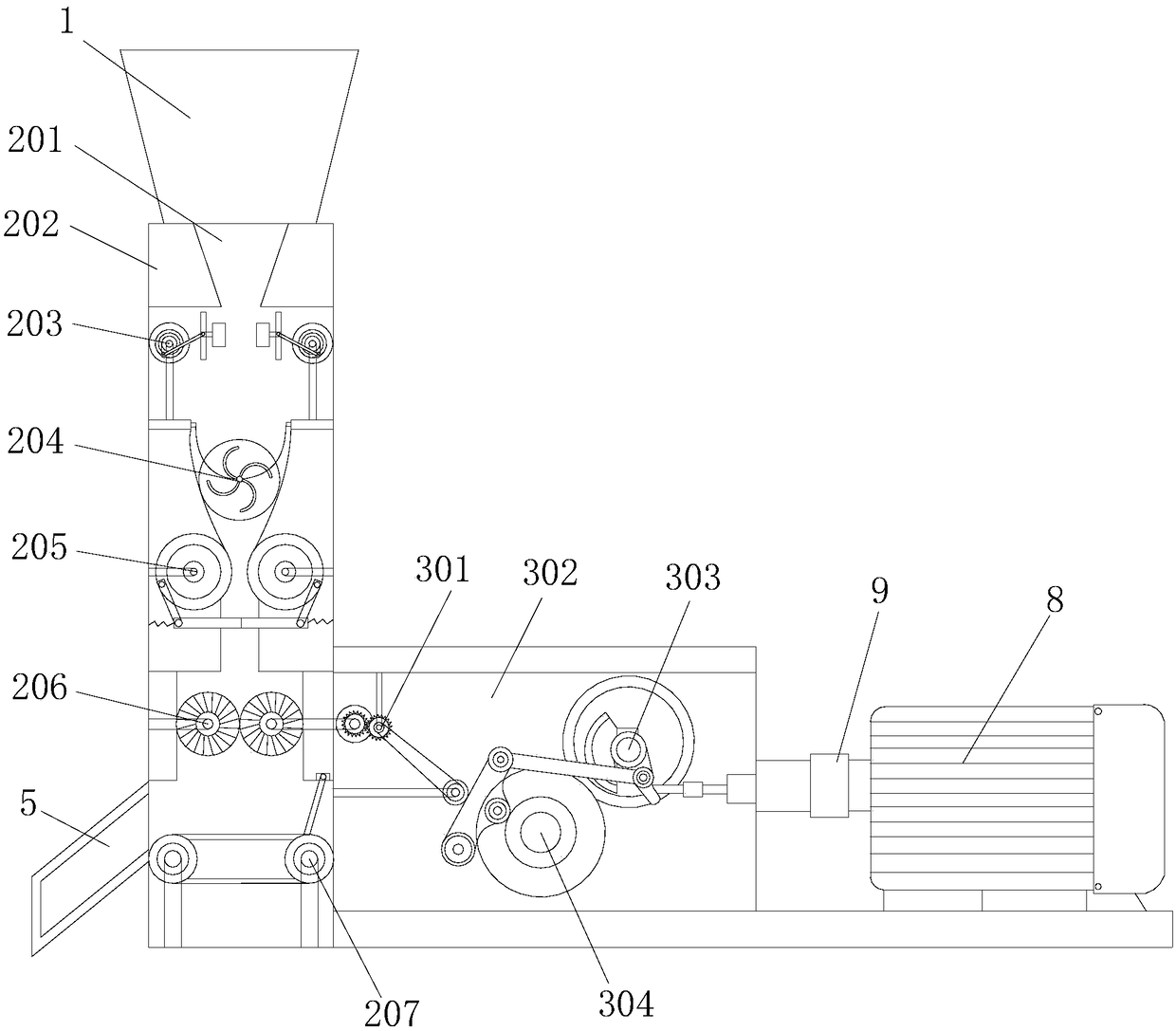

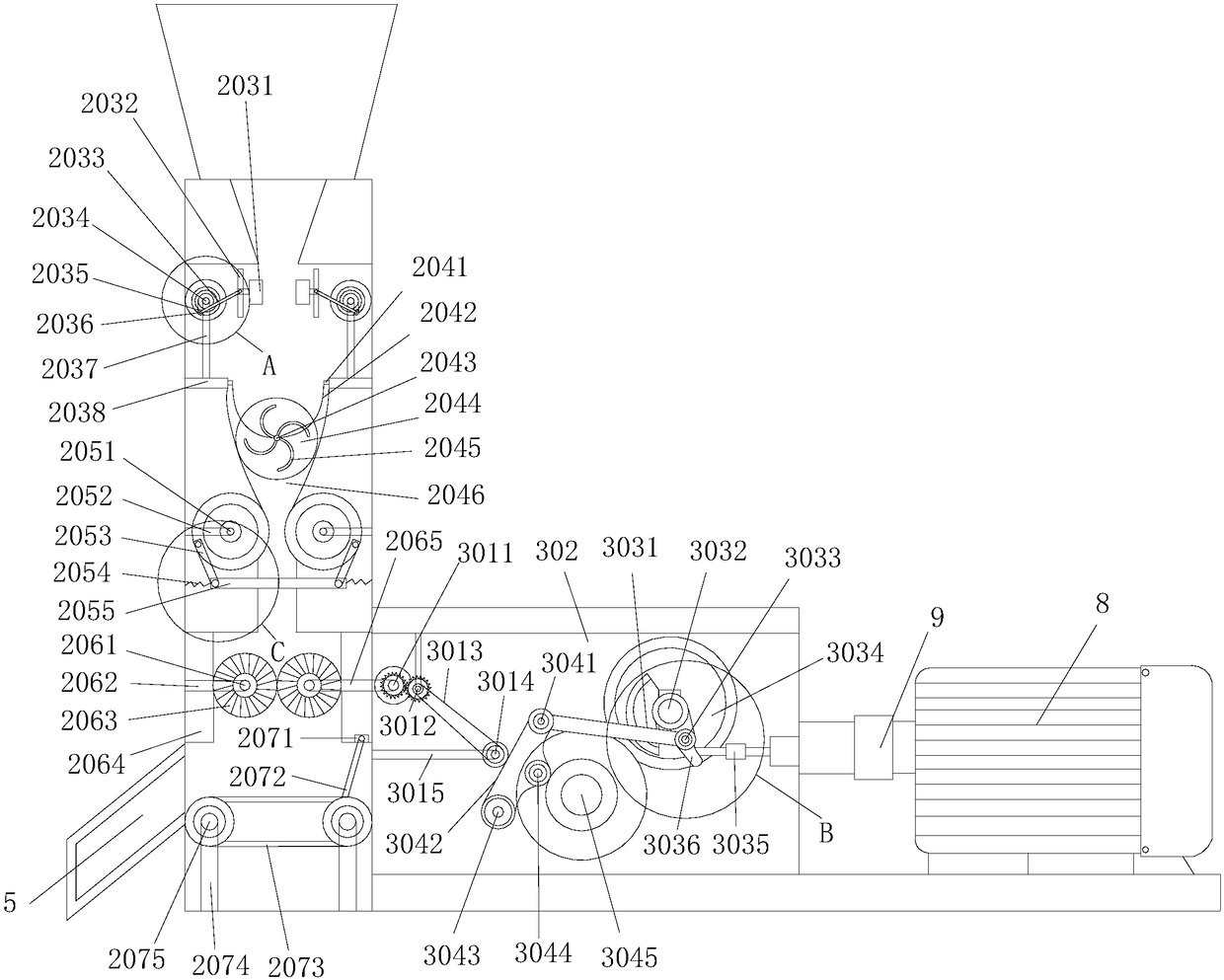

[0031] see Figure 1-Figure 7 , the present invention provides an automatic feed processing granulation device, the structure of which includes a feed inlet 1, a feed processing mechanism 2, a control box 3, a feed outlet 4, a discharge auxiliary plate 5, a base 6, a motor support seat 7, a motor 8. Coupling 9, the feed inlet 1 is a funnel-shaped structure and the bottom end is welded on the feed processing mechanism 2, and the feed processing mechanism 2 is a cylindrical structure. The bottom end and the control box 3 are welded into an integrated structure , the left end of the control box 3 is provided with a discharge port 4 and welded with the auxiliary discharge plate 5, the control box 3 and the motor support base 7 are installed on the base 6, and the bottom of the motor 8 passes through the motor support base 7 Fixed on the base 6, the feed processing mechanism 2 is composed of a material delivery port 201, a feed processing chamber 202, a rolling mechanism 203, a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com