Preparation method of composite aerogel type cigarette filter material

A composite aerogel and filter technology, which is used in e-liquid filters, tobacco, applications, etc., can solve the problems of poor adsorption performance and mechanical properties, and achieve the effects of improving mechanical properties, improving adsorption performance, and enriching pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

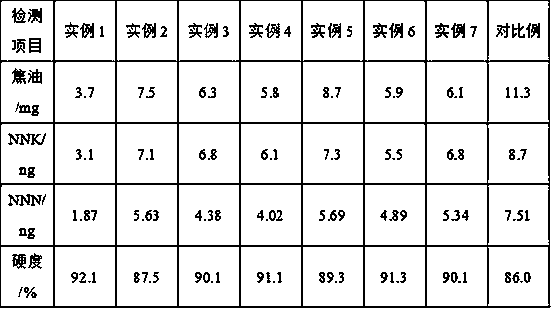

Examples

example 1

[0021] Pour oxalic acid, citric acid and water into a beaker at a mass ratio of 3:1:20, stir and dissolve with a glass rod for 30 minutes to obtain an organic acid solution; ball-mill the sepiolite, pass through a 500-mesh sieve, and sieve the After mixing the sepiolite and organic acid solution at a mass ratio of 1:20, ultrasonically impregnate at an ultrasonic frequency of 55kHz and a temperature of 55°C for 3 hours to obtain an impregnating solution, and transfer the obtained impregnating solution into a rotary evaporator. At a temperature of 75°C and a pressure of 600kPa, concentrate under reduced pressure for 5 hours to obtain No. 1 concentrated solution, and dry the obtained No. 1 concentrated solution at a temperature of 95°C for 4 hours, then transfer to a tube furnace. Under the condition of 400°C, heat preservation and roasting for 60 minutes, cool to room temperature with the furnace, and discharge the material to obtain pretreated sepiolite; then, after mixing the p...

example 2

[0023]Pour oxalic acid, citric acid and water into a beaker at a mass ratio of 3:1:20, stir and dissolve with a glass rod for 30 minutes to obtain an organic acid solution; in parts by weight, take 40 parts of carbomer, 10 parts Glycoprotein, 8 parts of phospholipid, 6 parts of carrageenan, 300 parts of water, first pour carbomer, phospholipid, carrageenan and water into the reaction kettle, and ultrasonically disperse for 4 hours at a temperature of 75 ° C and an ultrasonic frequency of 55 kHz Finally, add glycoprotein into the reaction kettle, then stir and react at a constant temperature for 5 hours at a temperature of 85°C and a rotation speed of 800r / min to obtain a mixed solution; Pour it into the mixer, under the condition of rotating speed 1200r / min, temperature 75℃, stir and mix at constant temperature for 6 hours, inject the material in the mixer into the mold through the syringe, and move the mold into the refrigerator, and keep it at - Pre-cooling at 28°C for 8 hou...

example 3

[0025] Pour oxalic acid, citric acid and water into a beaker at a mass ratio of 3:1:20, stir and dissolve with a glass rod for 30 minutes to obtain an organic acid solution; ball-mill the sepiolite, pass through a 500-mesh sieve, and sieve the After mixing the sepiolite and organic acid solution at a mass ratio of 1:20, ultrasonically impregnate at an ultrasonic frequency of 55kHz and a temperature of 55°C for 3 hours to obtain an impregnating solution, and transfer the obtained impregnating solution into a rotary evaporator. At a temperature of 75°C and a pressure of 600kPa, concentrate under reduced pressure for 5 hours to obtain No. 1 concentrated solution, and dry the obtained No. 1 concentrated solution at a temperature of 95°C for 4 hours, then transfer to a tube furnace. Under the condition of 400°C, heat-preserve and roast for 60 minutes, cool to room temperature with the furnace, and discharge the material to obtain pretreated sepiolite; in parts by weight, take 40 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com