Grinding system for cereals

A technology of whole grains and flour milling, applied in grain processing, cocoa, food science and other directions, can solve the problems of uncontrollable fire source, easy to cause combustion and explosion, simple structure, etc., to achieve a closed and safe working environment, no dust pollution, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

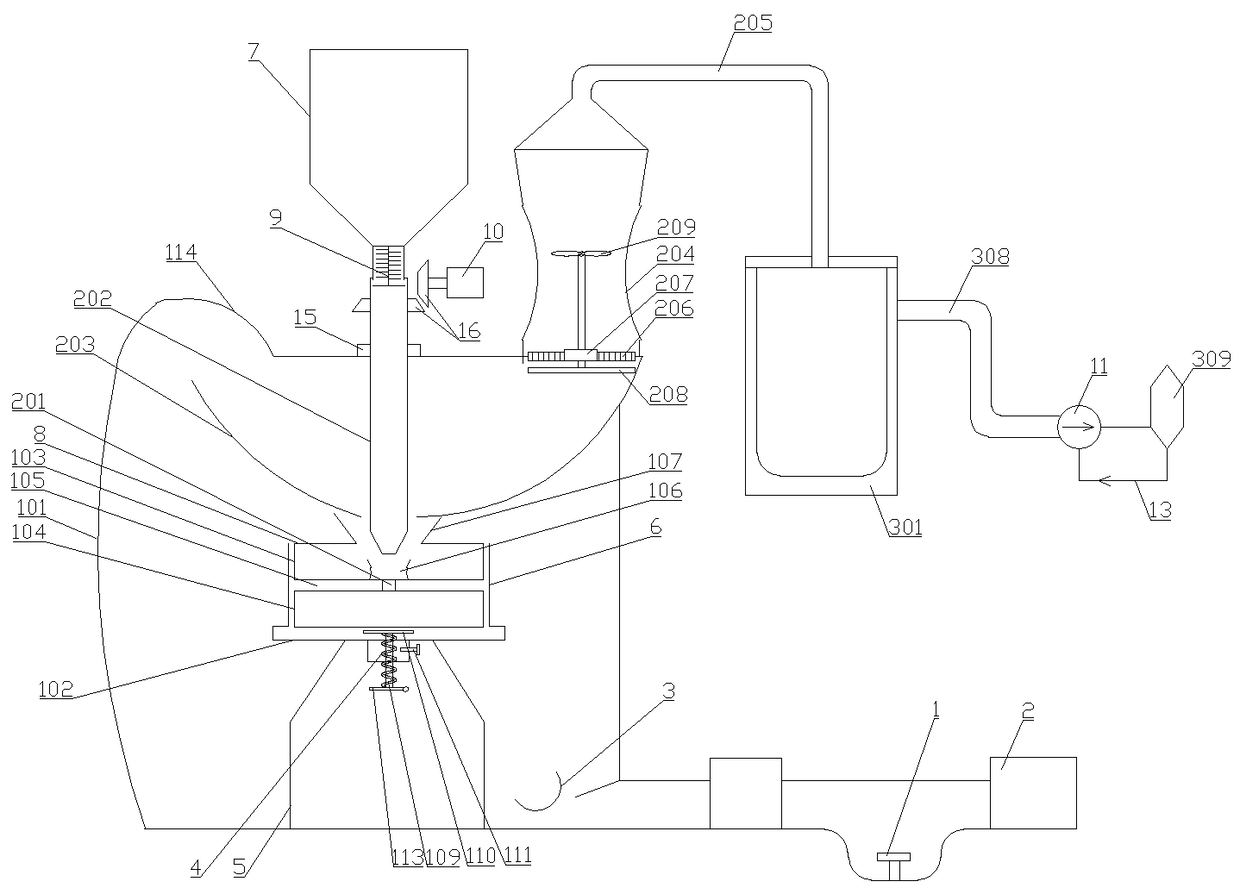

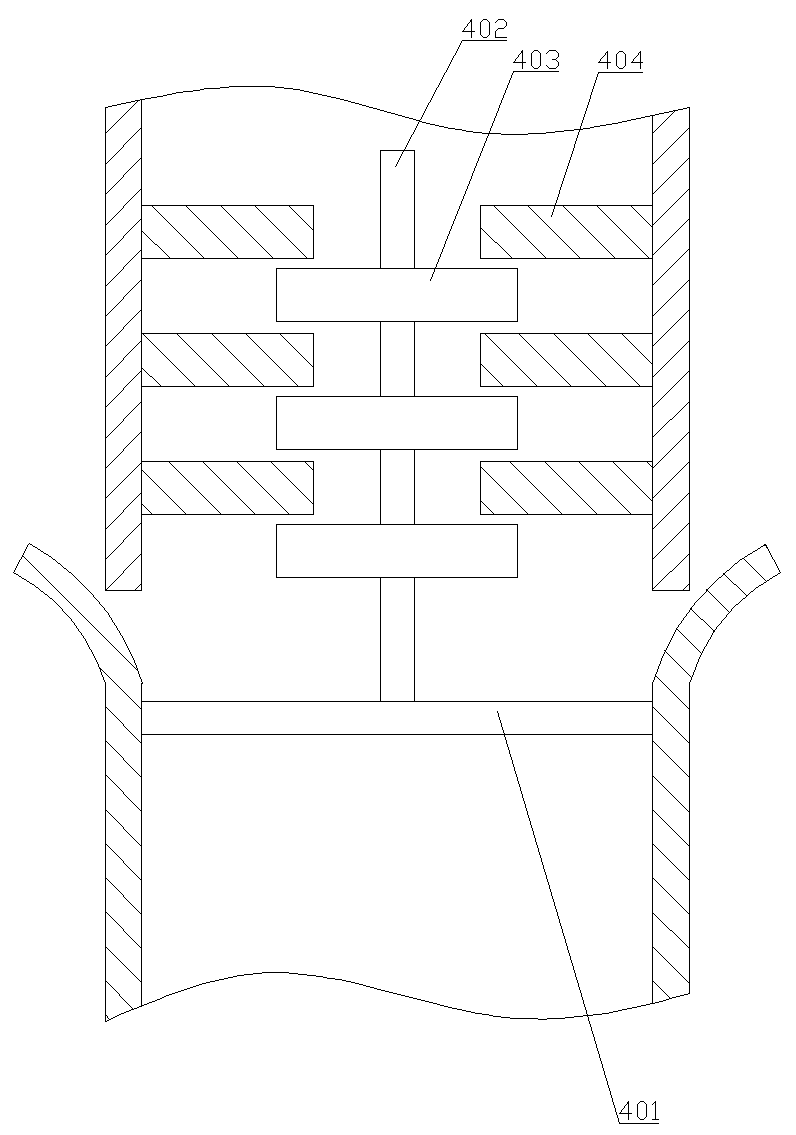

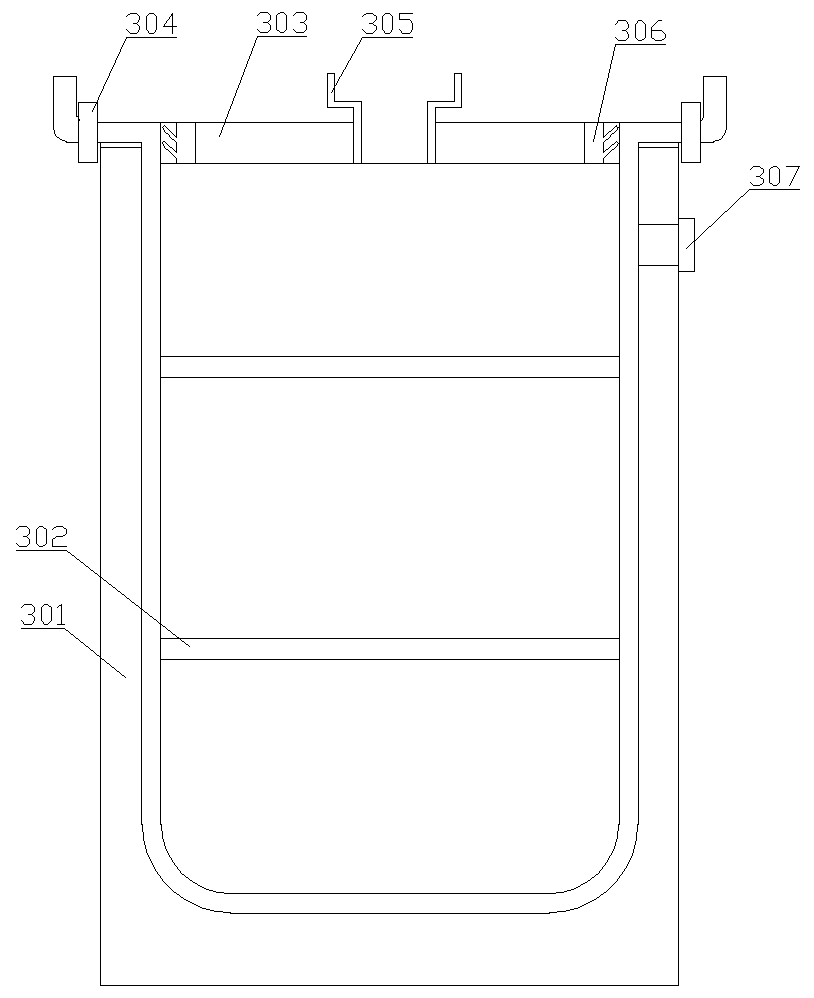

[0036] as attached Figure 1-7As shown, a system for milling whole grains includes a feeding mechanism, a milling mechanism connected to the feeding mechanism, a discharging mechanism connected to the milling mechanism, a flour collector connected to the discharging mechanism and a connecting The vacuum pump 11 on the flour collector; the powder milling mechanism includes a housing 101, a support 5 fixedly connected to the inside of the housing 101, a millstone 8 arranged on the support 5, and a feeding inlet and Powder outlet; the bottom corner of the side of the housing 101 is provided with a steam jet extractor 3 and a humidifier 1 connected to the steam jet extractor 3 . The housing 101 includes a left half of a wide cavity and a right half of a narrow cavity that are butted together, and a baffle plate 114 is arranged on the upper part of the left half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com