Electric dust remover with filtration type porous anode plates

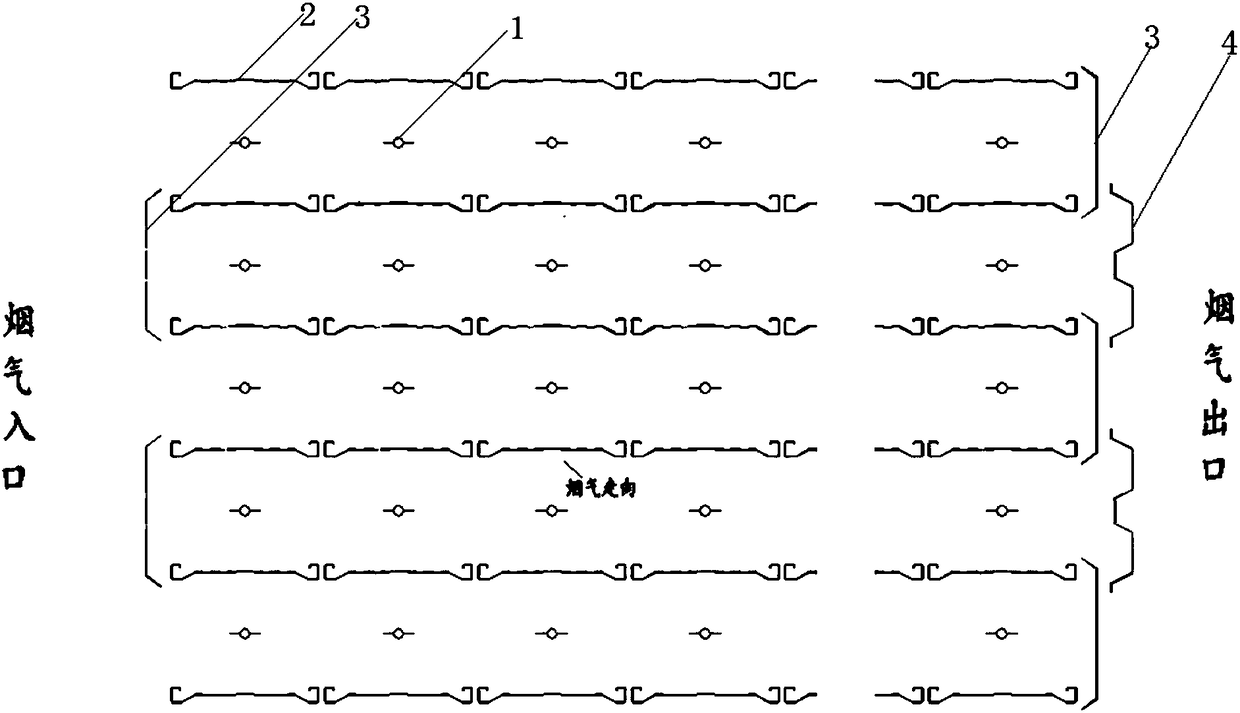

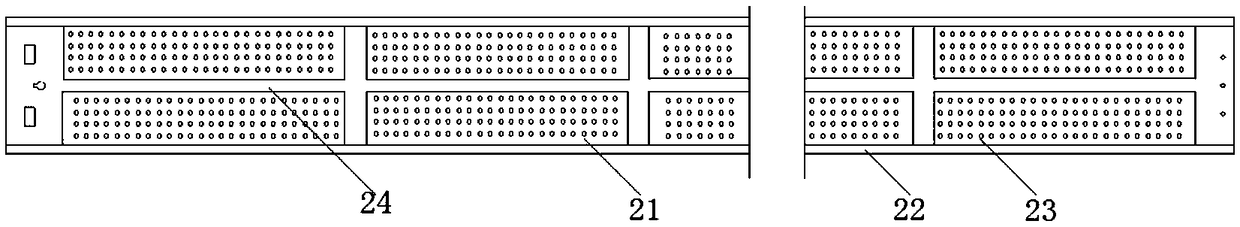

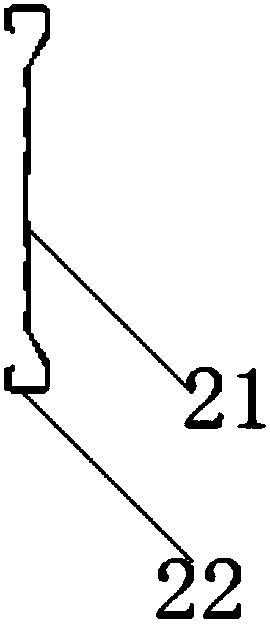

An electrostatic precipitator and porous anode technology, applied in the field of dust removal, can solve the problems of prolonged residence time, increased investment and floor space, and decreased work efficiency, so as to strengthen the ability to intercept and filter dust, improve the ability to intercept and filter dust, and improve the internal Good airflow balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Use an electrostatic precipitator to perform electrostatic precipitation treatment on the dusty flue gas, in which the flow velocity of the dusty flue gas is 1m 3 / s, the electrostatic precipitator is the electric precipitator provided by the present invention, the electric precipitator is provided with a flow-blocking dust collection plate and a porous dust collection plate, and a through hole is opened on the anode therein, and no The electrostatic precipitator is not equipped with a dust net; the content of PM2.5 in the dusty flue gas discharged from the electrostatic precipitator, that is, after being treated by the electrostatic precipitator, is 3.1mg / m 3 .

Embodiment 2

[0133] Utilize electrostatic precipitator to carry out electrostatic precipitating process to the dust-laden flue gas, wherein, the dust-laden flue gas to be treated is the same as the dust-laden flue gas of embodiment one, and its flow velocity is 1m 3 / s, the electrostatic precipitator is the electric precipitator provided by the present invention, the electric precipitator is provided with a flow-blocking dust collecting plate and a porous dust collecting plate, a through hole is opened on the anode therein, and a through hole is set in the through hole Raised, dust-attached net is also set in the electrostatic precipitator; the content of PM2.5 in the dusty flue gas treated by the electrostatic precipitator is 1.8mg / m 3 .

[0134] Through the above experimental examples and comparative examples, it can be known that the dust removal ability can be effectively improved and the content of PM2.5 in the tail gas can be reduced by opening a through hole on the anode plate and s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap