Energy-saving type corrodible waste disposal apparatus

A waste treatment equipment and energy-saving technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as excessive use of valve space, inconvenient opening and closing of sealed valves, manual scraping, etc. Achieve the effect of improving processing efficiency, realizing automatic operation, and saving valve switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited thereto.

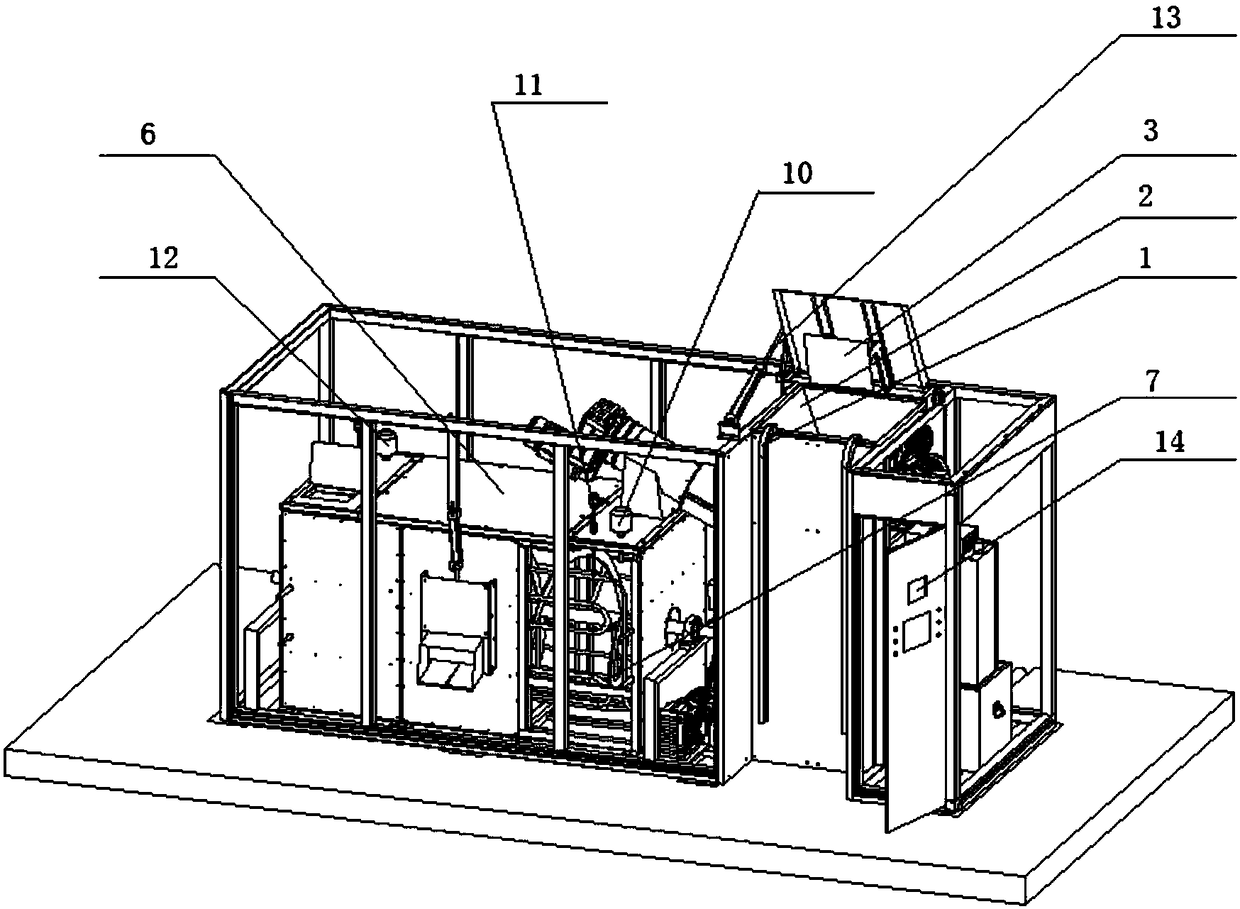

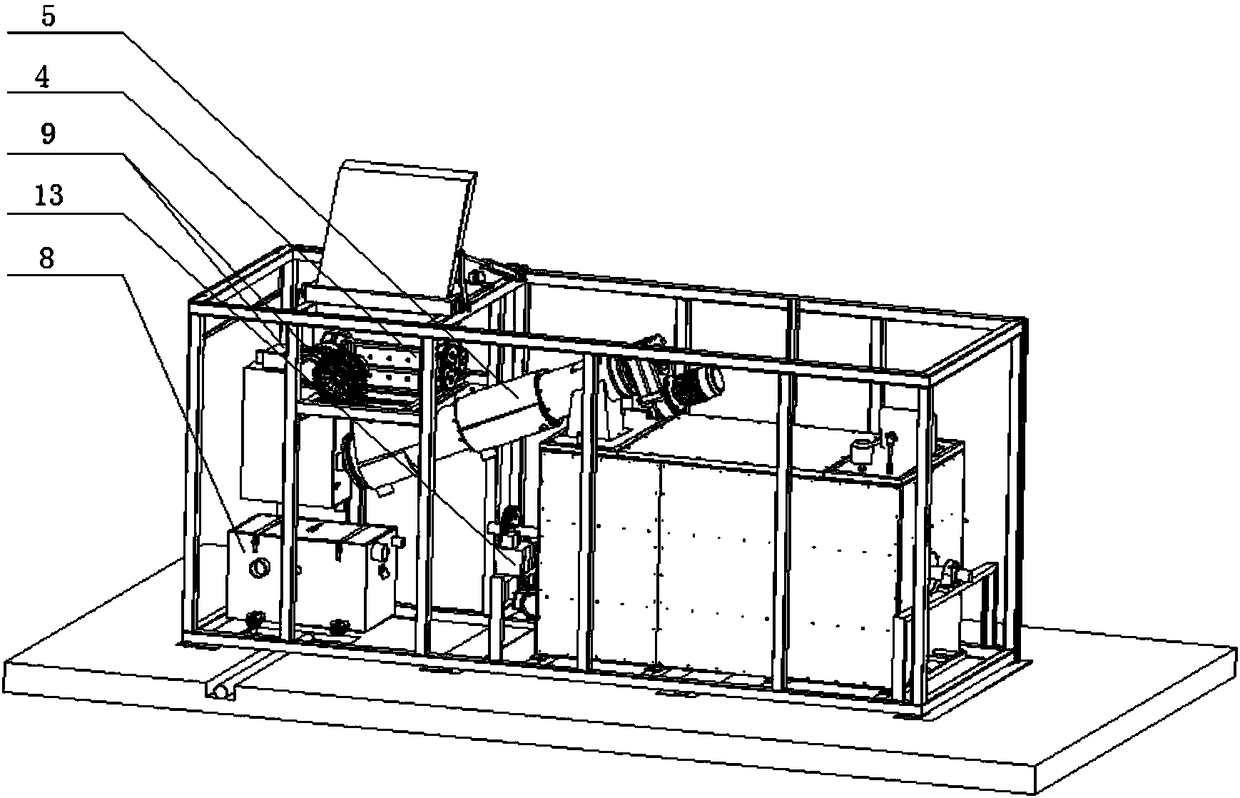

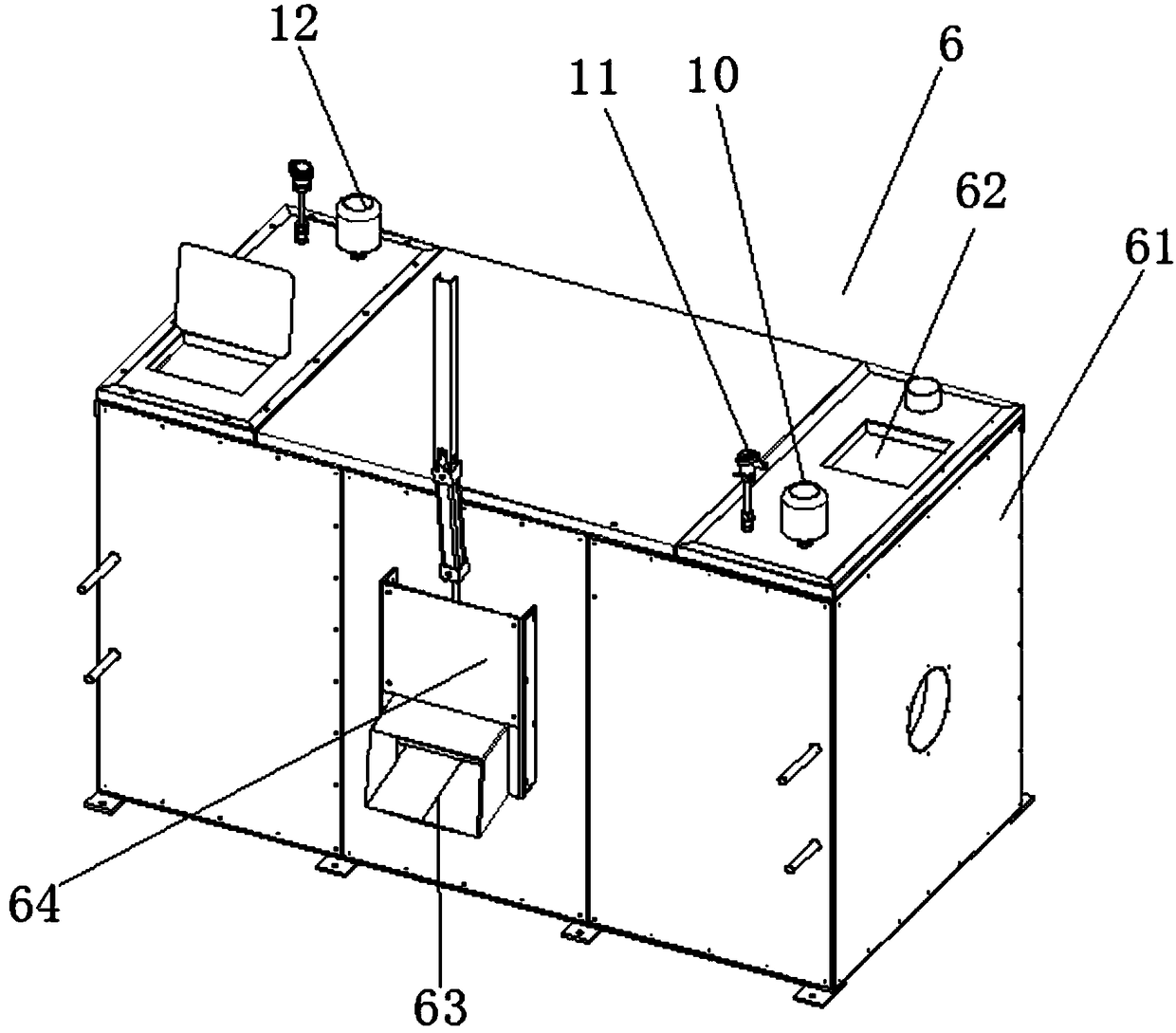

[0044] refer to Figure 1-2 , an energy-saving corrodible garbage treatment equipment, which includes an electric hoist 1, a feed hopper 2, a pressing device 3, a shredder 4, a squeezing machine 5, a fermentation tank 6, a stirring heating device 7, and an oil-water separation device 8 and exhaust gas treatment device 9, the electric hoist 1 is arranged on one side of the feed hopper 2, the pressing device 3 is located above the feed hopper 2, and the shredder is located below the feed hopper 2; the squeezer 5 is provided with Feed inlet, discharge port, liquid outlet and gas outlet, the feed inlet of extruder 5 communicates with the discharge port of shredder 4, and the discharge port of extruder 5 is positioned at the feed inlet top of fermentation box 6 , the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com