Method for machining centrifugal cylinder sleeve and integrated tool

A processing method and technology of a centrifugal cylinder, which are applied in the direction of tools, manufacturing tools, and metal processing equipment for lathes, can solve the problems of long empty moving paths, low processing efficiency, and long processing time, and increase the output. , high work efficiency, the effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

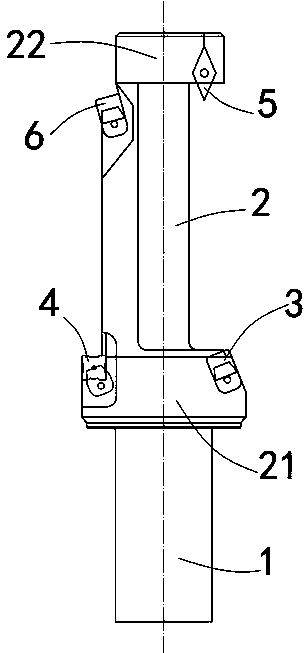

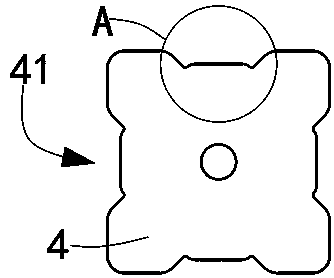

[0021] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0022] The invention provides a method for processing a centrifugal cylinder liner, which is processed by an integrated tool, comprising the following steps:

[0023] Step 1, machining the inner hole of the centrifugal cylinder liner;

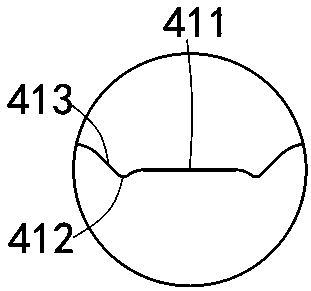

[0024] Step 2, move the tool, process the chamfer and R angle of the centrifugal cylinder liner, and process the centrifugal 45° chamfer, 22° chamfer, R angle of R0.3, and R angle of R0.8;

[0025] Step 3, move the tool to process the 60° outer chamfer of the centrifugal cylinder liner.

[0026] The method for processing the centrifugal cylinder liner provided by the present invention requires the use of integrated tools, and integrates multiple tools used in the traditional processing method into the same tool holder, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com