Robot assembly automatic hole searching method based on force feedback

A technology of force feedback and robotics, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inability to adapt to the shaft hole gap, low efficiency and non-universal, difficult to meet, etc., to avoid low efficiency and non-universal problems, increase Hole-seeking efficiency and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

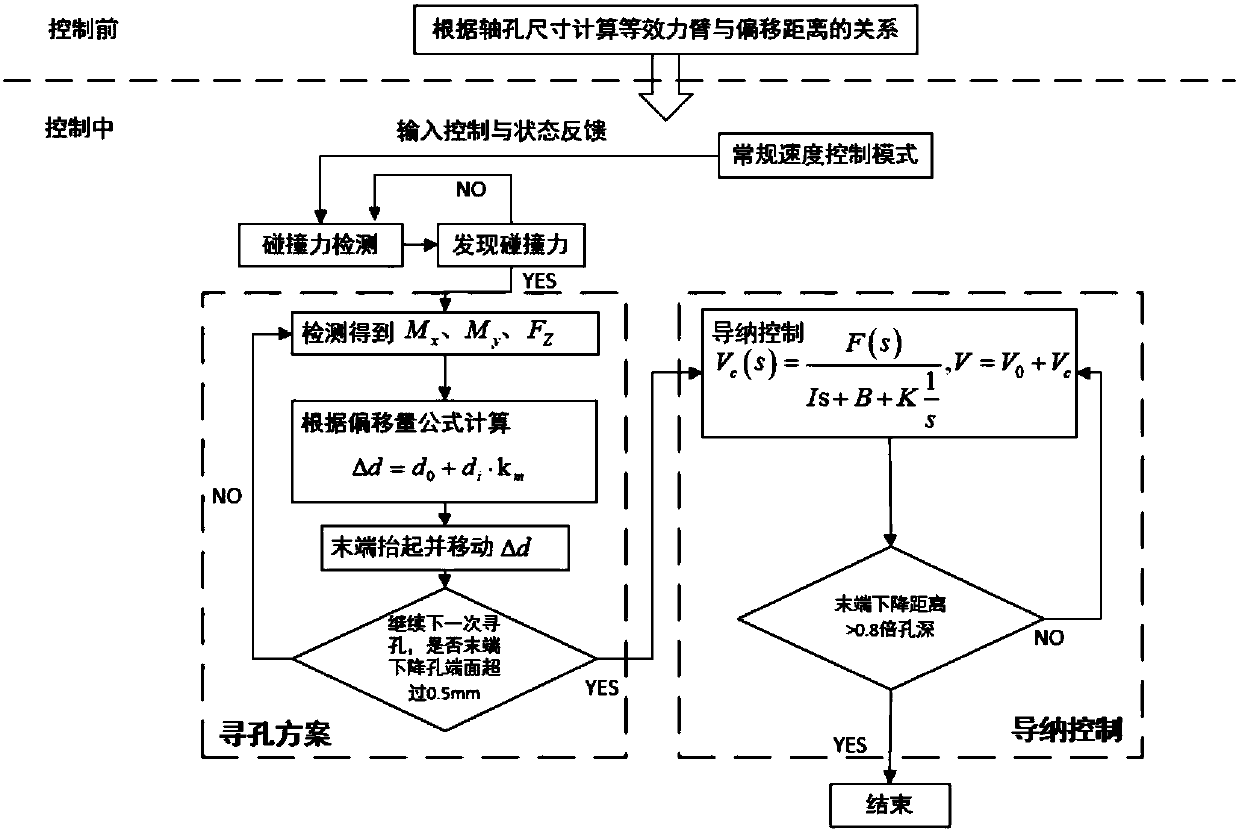

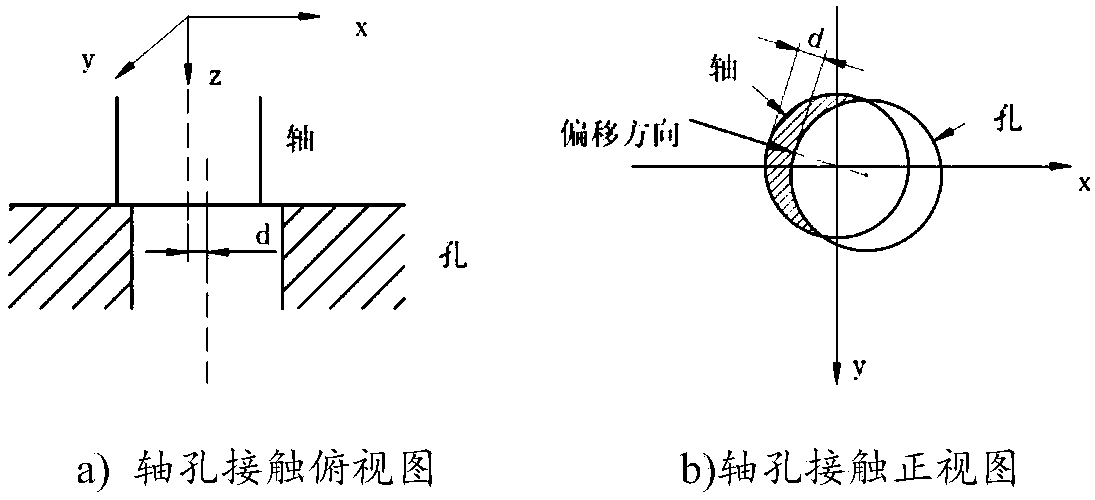

[0031] The invention aims to provide a variable-step-length hole-seeking method based on an equivalent force arm, which is applied to an industrial assembly process, solves the hole centering problem, and accelerates the hole-seeking process. Among them, an automatic hole-finding scheme with variable step length in the process of shaft-hole contact is adopted, combined with offline and online comprehensive calculation methods, and the six-dimensional force sensor information is used to face the inaccurate target position in actual operation. When there is an unknown error in the position of the target point, the axis can be adjusted accordingly according to the direction of the force and the direction of offset, so as to achieve the effect of automatic hole-seeking with variable step length, which has the advantage of speeding up the hole-seeking process, and is suitable for industrial assembly. The hole-seeking process under the imprecise target provides a new practical soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com