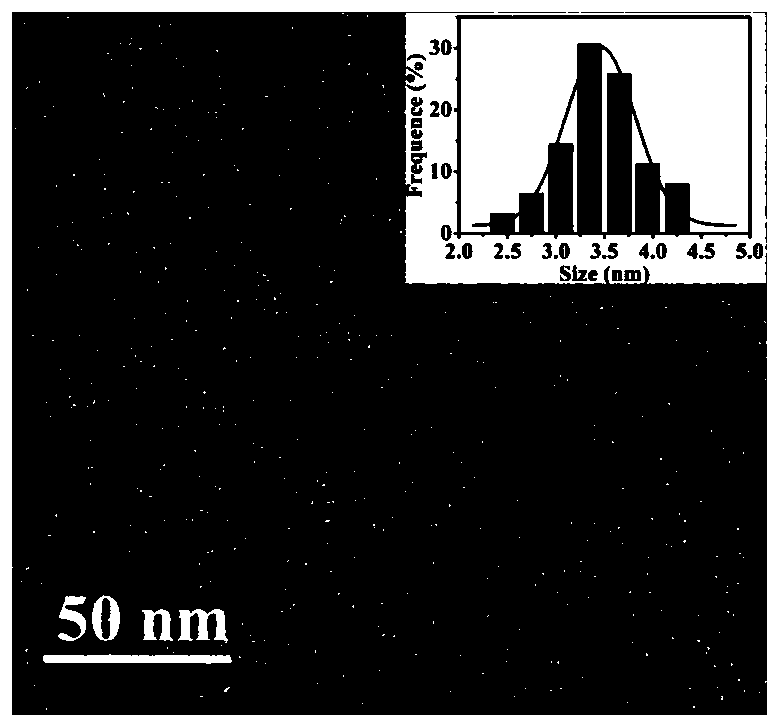

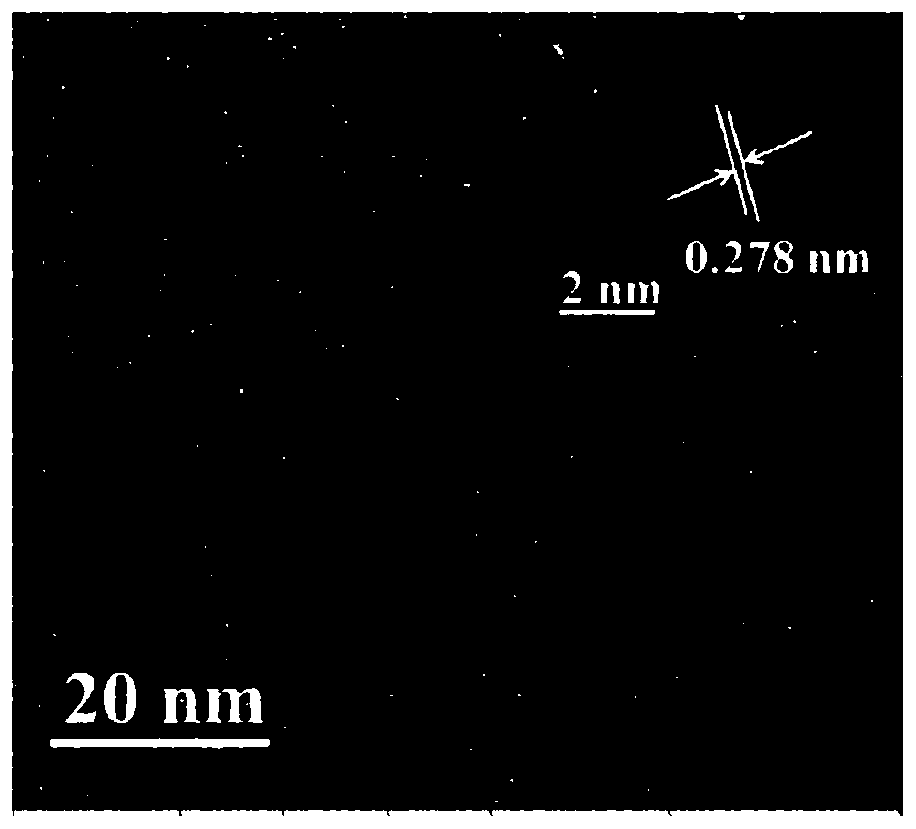

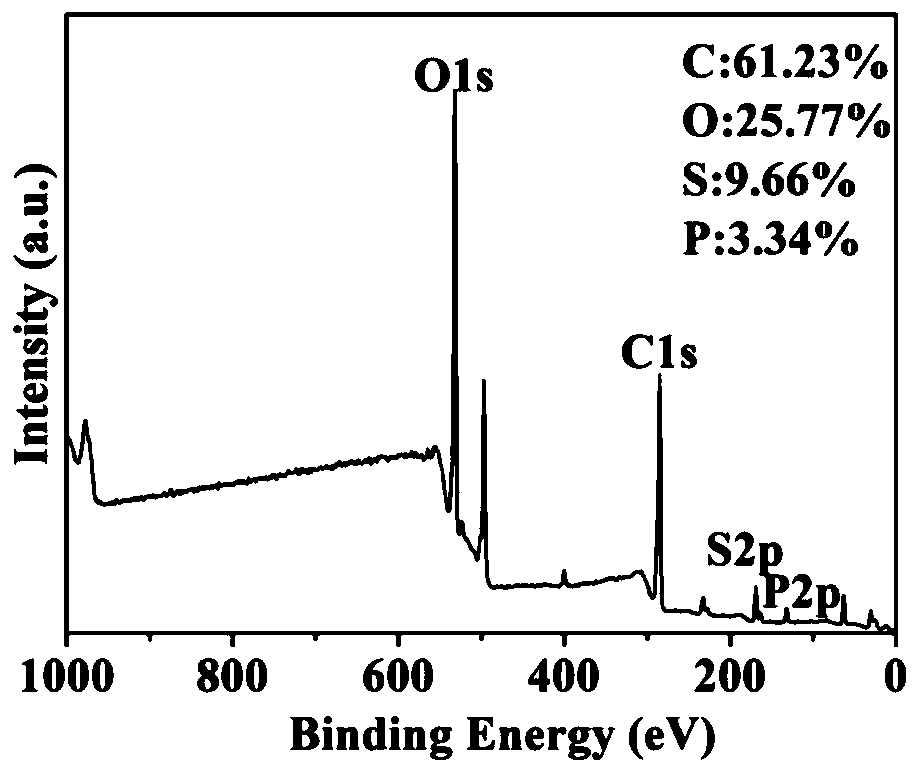

A preparation method for synthesizing sulfur-phosphorus co-doped graphene quantum dots

A graphene quantum dot and co-doping technology, which is applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc. problem, to achieve the effect of simple and controllable synthesis process and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the first step, add 0.576g of citric acid monohydrate, 0.682g of sodium phytate and 0.142g of anhydrous sodium sulfate into a 50mL container respectively, then add 20mL of deionized water, stir and dissolve to form a clear solution.

[0038] In the second step, the clear solution obtained in the first step was transferred to a 30mL polytetrafluoroethylene-lined stainless steel autoclave, and the oven temperature was set at 160°C, 170°C, 180°C, 190°C, and 200°C for hydrothermal treatment for 7 hours. , and then naturally cooled to room temperature to obtain a dark yellow solution.

[0039] In the third step, the cooled dark yellow solution was transferred from the reaction kettle to a 50 mL centrifuge tube, and centrifuged at 9000 rpm for 20 min to remove larger suspended particles.

[0040] In the fourth step, in a 25mL container, pour the centrifuged supernatant into a vacuum filtration device for suction filtration (the filter membrane adopts a 0.45 μm cellulose ac...

Embodiment 2

[0043] The first step, as embodiment 1.

[0044] In the second step, the clarified solution obtained in the first step was transferred to a 30mL polytetrafluoroethylene-lined stainless steel autoclave, and the oven temperature was set at 180°C, and the hydrothermal treatment was carried out for 4h, 5h, 6h, 7h, 8h, and 9h respectively. Then it was naturally cooled to room temperature to obtain a dark yellow solution.

[0045] The 3rd step, as embodiment 1.

[0046] The 4th step, as embodiment 1.

[0047] The 5th step, as embodiment 1.

Embodiment 3

[0049] In the first step, add citric acid monohydrate 0.192g, 0.192g, 0.384g, 0.576g, 0.768g, 0.960g, 1.152g, sodium phytate 1.364g, 0.682g, 0.682g, 0.682g, 0.682g to a 50mL container g, 0.682g and 0.142g of anhydrous sodium sulfate, then add 20mL of deionized water, stir and dissolve to form a clear solution. At this time, the molar ratios of citric acid and sodium phytate are 1:2, 1:1, 2:1, 3:1, 4:1, 5:1, and 6:1, respectively.

[0050] In the second step, the clear solution obtained in the first step was transferred to a 30mL polytetrafluoroethylene-lined stainless steel autoclave, and the oven temperature was set at 180°C for hydrothermal treatment for 7h, and then naturally cooled to room temperature to obtain a dark yellow solution.

[0051] The 3rd step, as embodiment 1.

[0052] The 4th step, as embodiment 1.

[0053] The 5th step, as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com