PP composite material with negative ion release function, preparation method and application thereof

A composite material and negative ion technology, applied in the field of automotive interior materials, can solve the problems of complex preparation process, easy migration, poor environmental protection performance, etc., and achieve the effects of improving sterilization and bacteriostatic effect, increasing the amount of negative ions released, and reducing the content of VOC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

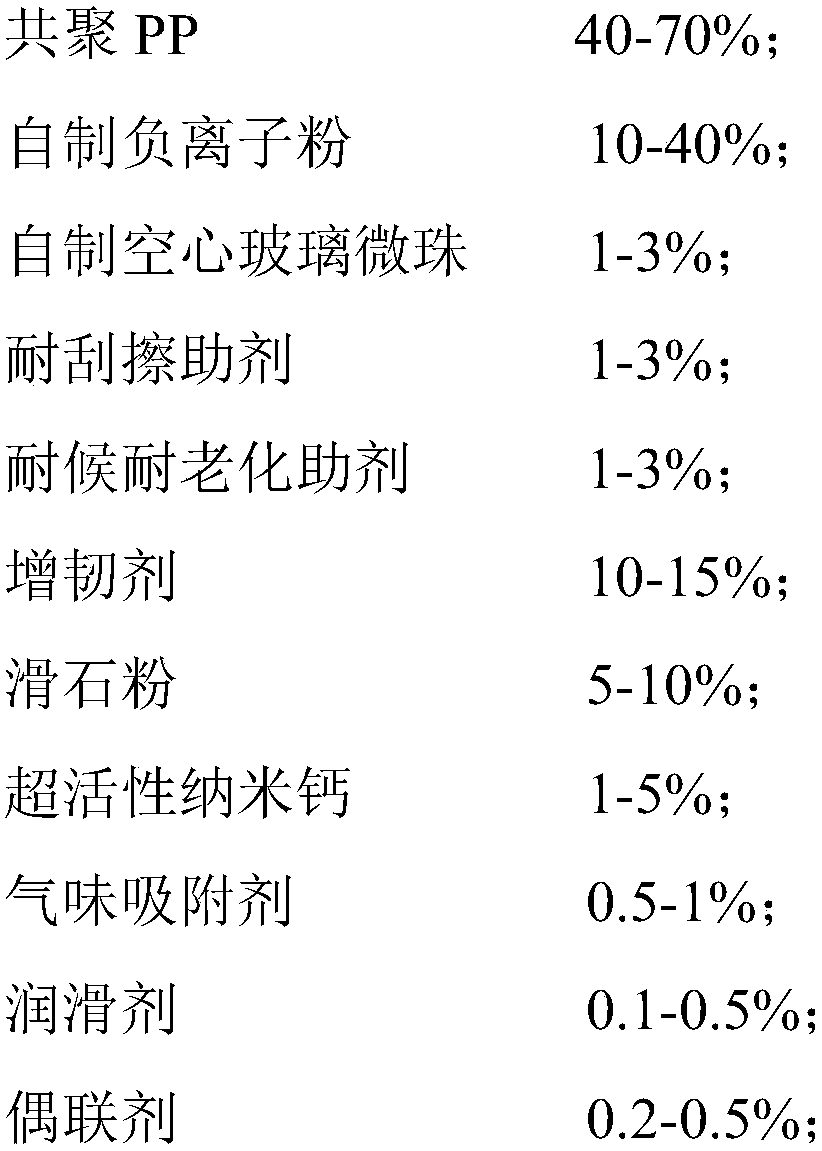

[0042] A kind of PP composite material with the function of releasing negative ions, the composition is as follows by weight percentage:

[0043]

[0044] (1) Add the copolymerized PP, coupling agent, and toughening agent in proportion to the high-speed mixer and mix for 3-5min at a speed of 50-80r / min;

[0045] (2) Mix self-made negative ion powder, talcum powder, and odor absorbing agent at a speed of 80-100r / min for 2-4min so that each component can be fully mixed evenly;

[0046] (3) Add the remaining weather-resistant and anti-aging additives, lubricants, super-active nano-calcium, scratch-resistant additives, and self-made hollow glass microspheres into the mixer and mix for 1-2 minutes;

[0047] (4) Extrude the mixed raw materials in a twin-screw extruder with a length-to-diameter ratio of 40:1. The processing temperature of the extruder is set to ten temperature zones, and the temperature of each temperature zone is 180°C, 190°C, 200°C, 210°C, 210°C, 210°C, 210°C, ...

Embodiment 2

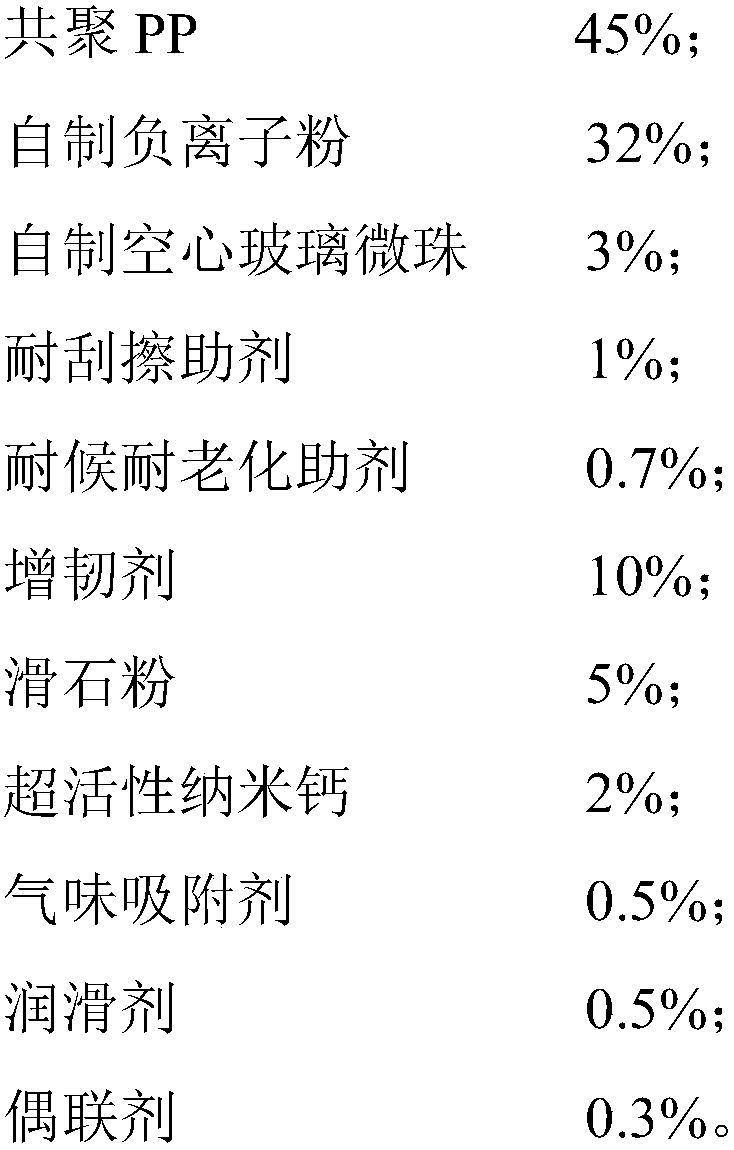

[0049] A kind of PP composite material with the function of releasing negative ions, the composition is as follows by weight percentage:

[0050]

[0051] The preparation method of the PP composite material with the function of releasing negative ions is the same as that of Example 1.

Embodiment 3

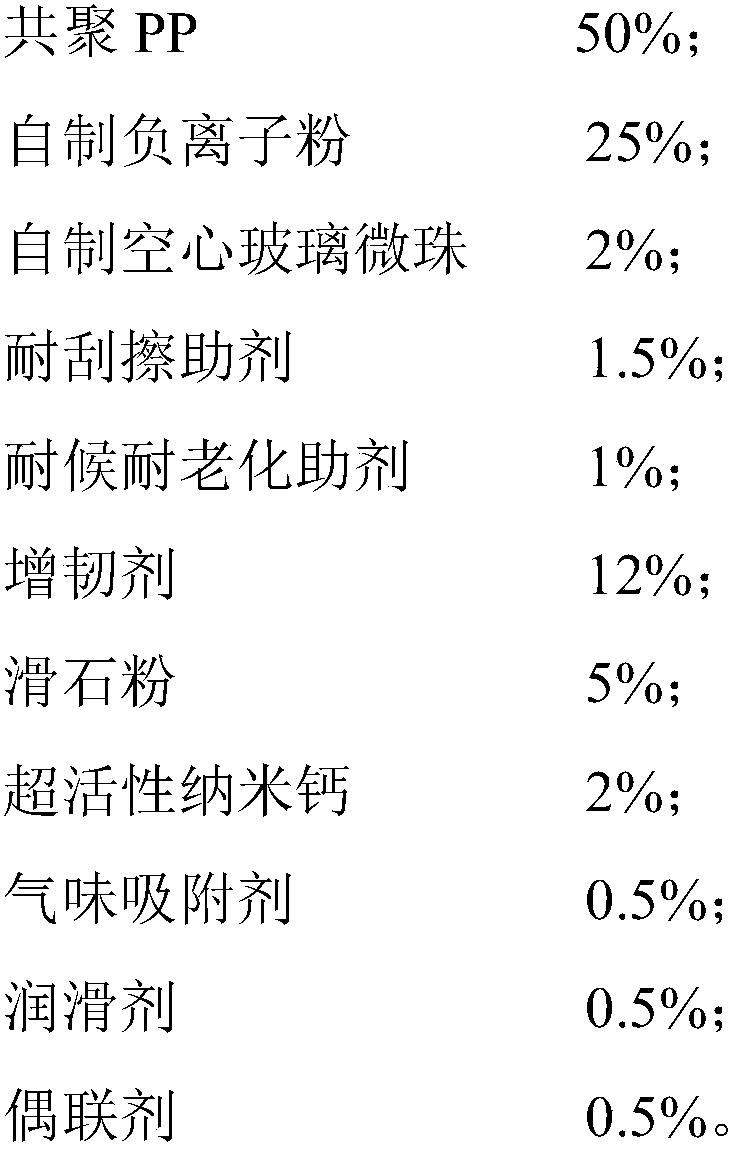

[0053] A kind of PP composite material with the function of releasing negative ions, the composition is as follows by weight percentage:

[0054]

[0055]

[0056] The preparation method of the PP composite material with the function of releasing negative ions is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com