SMFC manganous-manganic oxide/tourmaline composite cathode and preparation method thereof

A technology of trimanganese tetraoxide and composite cathode, which is applied in electrical components, battery electrodes, biochemical fuel cells, etc., can solve the problems of low power generation efficiency, complex cathode structure, and cost reduction, and achieve the improvement of specific surface area and activity. The production process is simple and the effect of increasing the amount of negative ions released

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

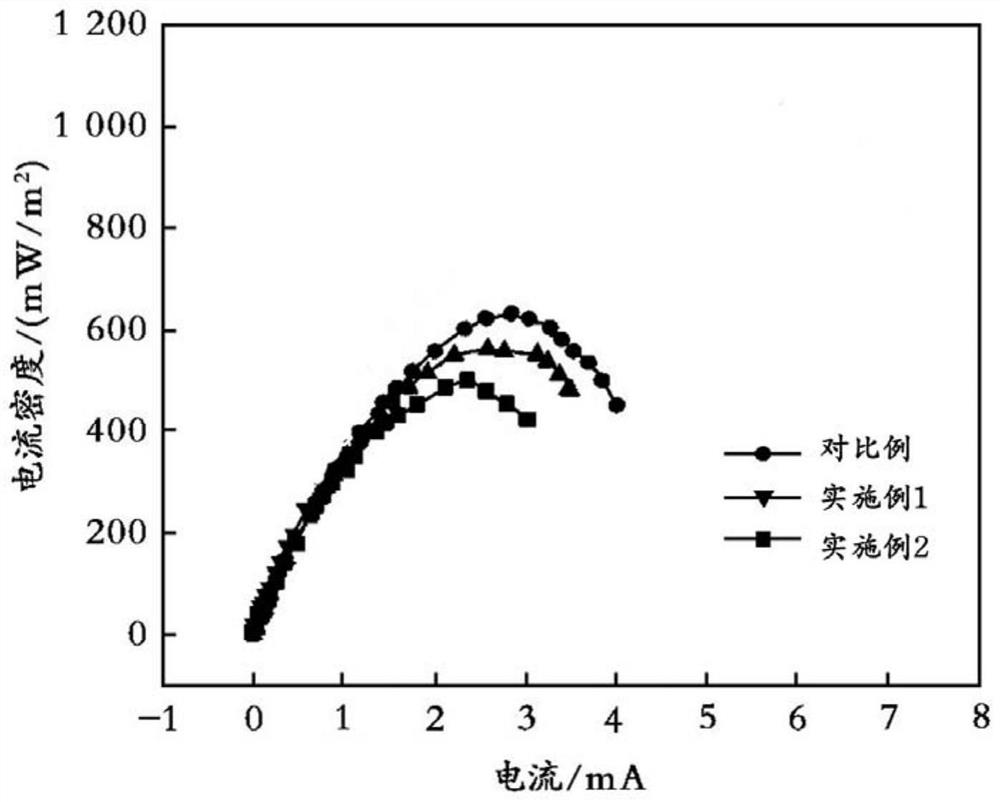

[0029] The invention provides a SMFC trimanganese tetraoxide / tourmaline composite cathode, the SMFC trimanganese tetraoxide / tourmaline composite cathode includes a rolled activated carbon substrate, a composite catalyst material and an adhesive, and the rolled activated carbon substrate It includes a stainless steel net, an air diffusion layer and a catalyst layer, and the composite catalyst material is composed of modified trimanganese tetraoxide and modified tourmaline.

[0030] In a preferred embodiment, the binder is polytetrafluoroethylene suspension, and the mass concentration of the polytetrafluoroethylene suspension is 70%wt.

[0031] A preparation method of SMFC trimanganese tetraoxide / tourmaline composite cathode, comprising the following steps:

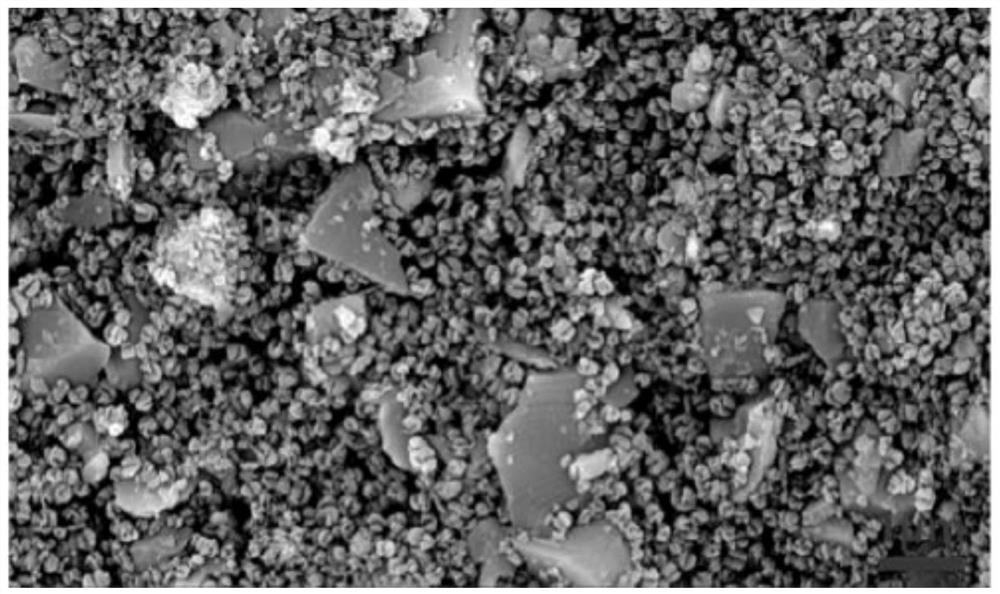

[0032] Step 1: Preparation of rolled activated carbon substrate, cut the selected stainless steel mesh into long strips, roll the air diffusion layer to one side of the stainless steel mesh, and roll the catalyst layer to t...

Embodiment 2

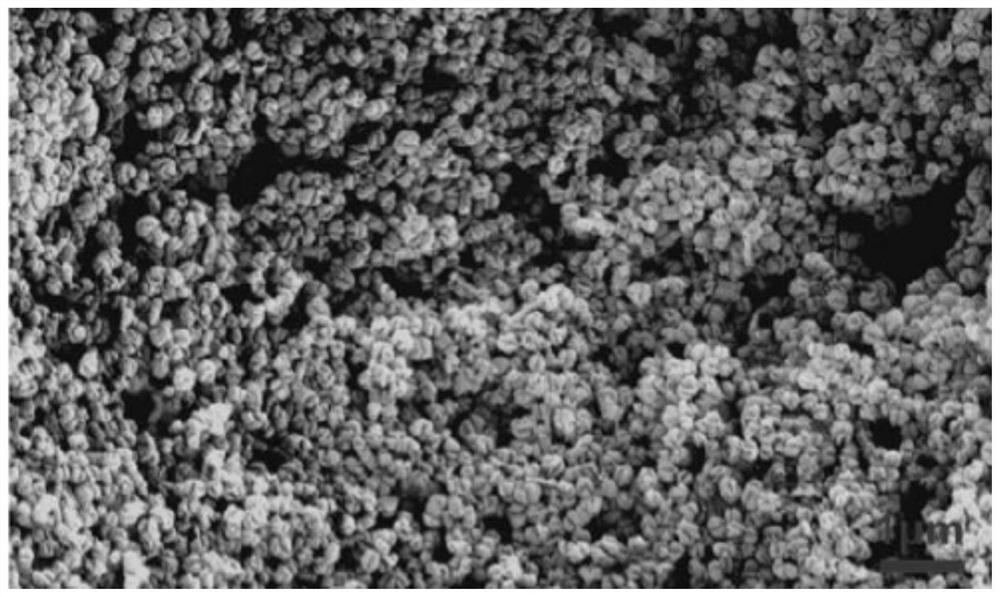

[0043] Different from embodiment 1, the present invention provides a kind of SMFC trimanganese tetraoxide / tourmaline composite cathode, and described composite catalyst material is modified trimanganese tetraoxide, does not comprise tourmaline, and the weight of described composite catalyst material is 0.563g, the physical picture of the SMFC trimanganese tetraoxide / tourmaline composite cathode under SEM is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com