Polyether block amide thermal shrinkable sleeve pipe, and preparation method thereof

A technology of polyether block amide and heat-shrinkable sleeves, which is applied in the field of polyether block amide heat-shrinkable sleeves, can solve the problems of poor material flexibility, easy hydrolysis of polyester groups, and high price, so as to achieve a variety of applications , Excellent anti-static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned polyether block amide heat-shrinkable sleeve comprises the following steps:

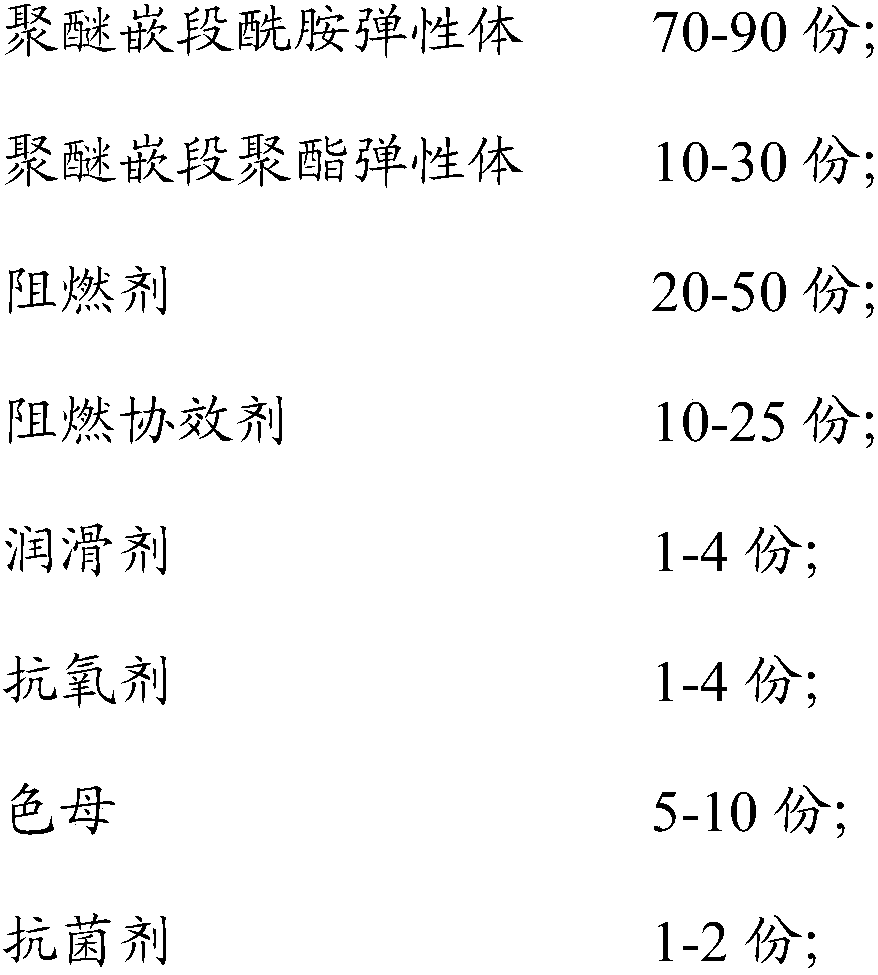

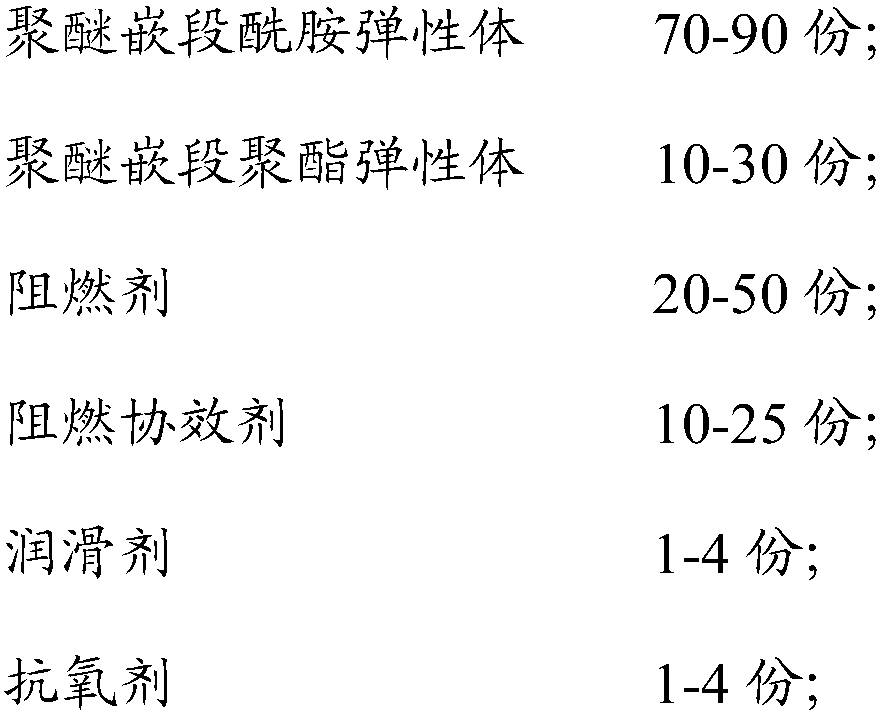

[0035] Step 1: Take the following components in parts by weight: 70-90 parts of polyether block amide elastomer, 10-30 parts of polyether block polyester elastomer, 20-50 parts of flame retardant, flame retardant 10-25 parts of effect agent, 1-4 parts of lubricant, 1-4 parts of antioxidant, 5-10 parts of color masterbatch, 1-2 parts of antibacterial agent;

[0036] Step 2: Put the components of step 1 into a high-speed mixer, and mix and stir for 2-5 minutes at a speed of 500-800r / min;

[0037] Step 3: Mix and granulate the mixture obtained in Step 2 through a twin-screw extruder at 180-220°C to produce a masterbatch;

[0038] Step 4: Dry the masterbatch obtained in Step 3 at 50-80°C for 4-8 hours with a dryer;

[0039] Step 5: Put the dried masterbatch into the single-screw extruder, and under the condition of 170-210°C, transfer and compress th...

preparation Embodiment 1

[0043] Calculated by weight, take the following material parts:

[0044] 90 parts of polyether block amide elastomer (specifically take 45Kg of the Pebax series 5533 and 2533 grades of ARKERMA);

[0045] 10 parts of polyether block polyester elastomer (specifically take 10Kg of DUPONT company Hytrel series 4056 grade material);

[0046] 30 parts of flame retardant (specifically get 30Kg of decabromodiphenylethane);

[0047] 15 parts of flame retardant synergist (specifically 5Kg of antimony trioxide and 10Kg of zinc borate);

[0048] 2 parts of lubricant (specifically take EBS as 1Kg and zinc stearate as 1Kg);

[0049] 4 parts of antioxidant (concretely take antioxidant 1098 as 2Kg, antioxidant 168 as 2Kg);

[0050] 5 parts of color masterbatch (specifically take PA12 as the base material masterbatch 5Kg)

[0051] 2 parts of antibacterial agent (specifically take 2-(4-thiazolyl)benzimidazole (TBZ) 1Kg, 8-hydroxyquinoline copper 1Kg)

preparation Embodiment 2

[0053] Calculated by weight, take the following material parts:

[0054] 80 parts of polyether block amide elastomer (specifically take 40Kg of the Pebax series 5533 and 2533 grades of ARKERMA);

[0055]20 parts of polyether block polyester elastomer (specifically take DUPONT company Hytrel series 4056 grade material 20Kg);

[0056] 50 parts of flame retardant (specifically get 50Kg of decabromodiphenylethane);

[0057] 25 parts of flame retardant synergist (specifically 15Kg of antimony trioxide and 10Kg of zinc borate);

[0058] 1 part of lubricant (specifically take EBS as 1Kg);

[0059] 1 part of antioxidant (specifically take antioxidant 1098 as 0.5Kg, antioxidant 168 as 0.5Kg);

[0060] 8 parts of color masterbatch (specifically take PA12 as the base masterbatch 8Kg)

[0061] 1 part of antibacterial agent (specifically take 2-(4-thiazolyl) benzimidazole (TBZ) 1Kg)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com