A kind of anti-condensation ice-containing sand mist sealing layer material and preparation method thereof

A fog-sealing material and anti-icing technology, applied in coatings, asphalt coatings, etc., can solve the problem of incompatibility between anti-icing agents and sand-containing fog-sealing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The embodiment of the invention also discloses a preparation method of an anti-icing sealing layer material containing sand mist. Specifically, the preparation method includes the following steps:

[0053] The raw materials are evenly mixed to obtain the anti-icing and sand mist sealing layer material.

[0054] Wherein, the anti-icing and sand-mist sealing layer material is the anti-icing and sand-mist sealing layer material of the above-mentioned embodiment. Therefore, the raw materials of the anti-icing and sand mist sealing layer material include the following components in parts by weight: 20-40 parts of anti-icing agent, 100 parts of emulsified asphalt, 15-30 parts of thickening mixed solution and 40 parts of aggregate ~60 servings. Wherein, the anti-icing agent is composed of ice-melting salt and a hydrophobic agent, and the hydrophobic agent is coated with the ice-melting salt.

[0055] The preparation method of each raw material of the anti-icing and sand-mis...

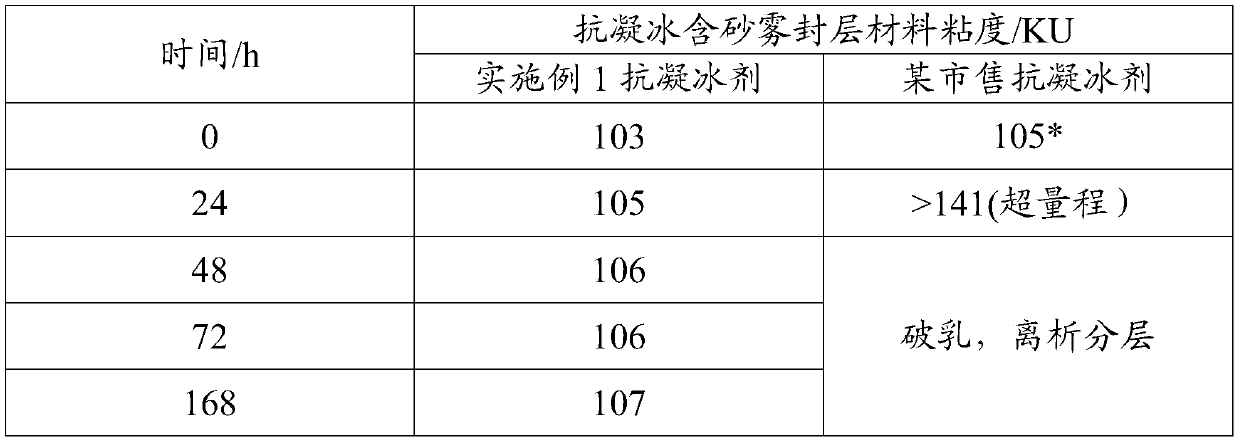

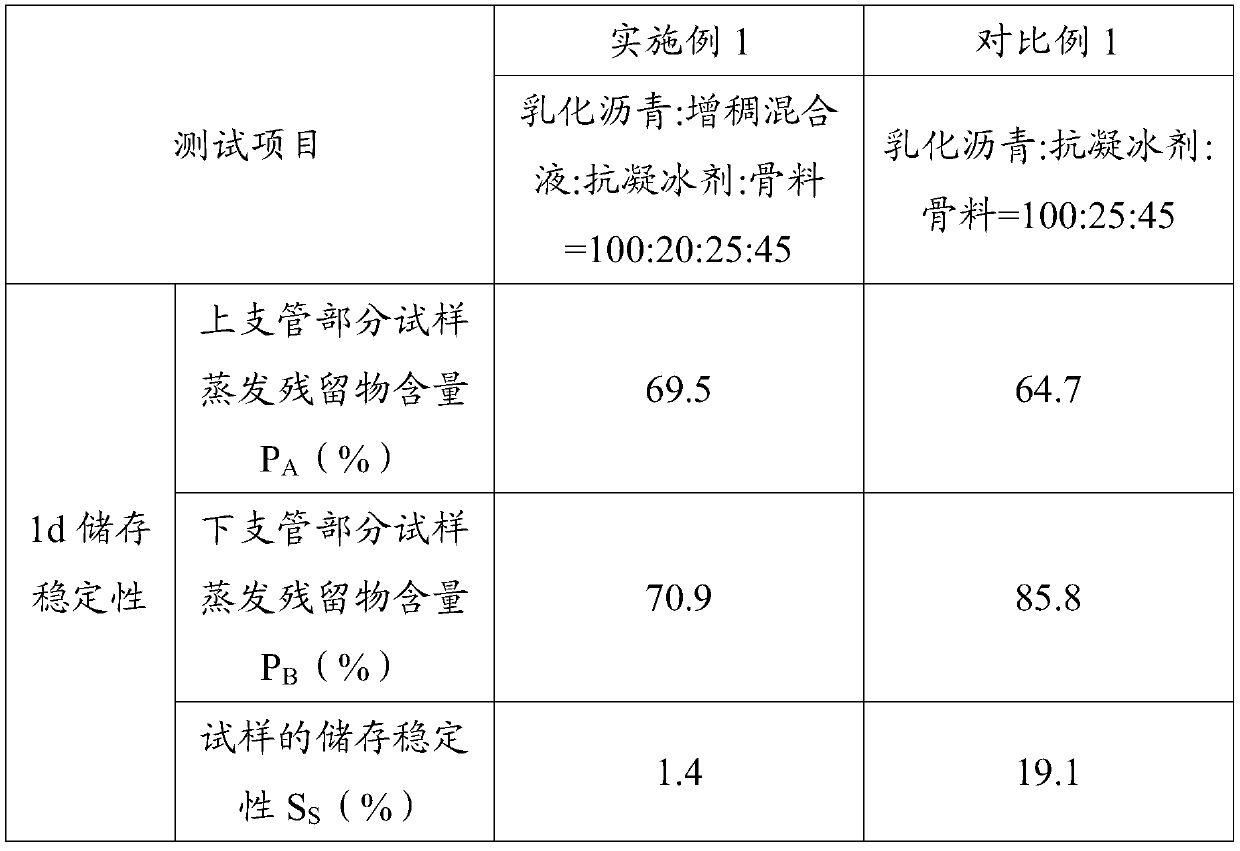

Embodiment 1

[0062] Embodiment 1 specifically prepares the anti-condensation ice-containing sand mist sealing layer material through the following process:

[0063] (1) Weigh 110g of sodium chloride and disperse it in 200g of water, stir well to obtain an ice-melting saline solution. Add 160 g of dried diatomaceous earth into the ice-melting saline solution, and stir and disperse with a disperser at 600 r / min and 55° C. for 12 hours to obtain the first mixture. Then put the first mixture in a vacuum drying oven at 90°C, and dry the first mixture to a constant weight under the condition of a vacuum of -0.04 to -0.06MPa, take it out and grind it until it passes through a 100-mesh sieve to obtain a molten ice aggregate.

[0064] (2) Add 10 g of isobutyltriethoxysilane to 100 g of n-butanol to obtain an organic solution of a hydrophobic agent. Then add 200 g of the ice-melting aggregate obtained in the above step (1) into the organic solution of the hydrophobic agent, stir evenly with a disp...

Embodiment 2

[0078] Example 2 The anti-icing and sand mist sealing layer material is specifically prepared through the following process:

[0079] (1) Take 136g of magnesium chloride and disperse it in 200g of water, and stir to obtain the ice-melting saline solution. Add 180 g of dried fly ash into the ice-melting brine solution, and stir and disperse with a disperser at 600 r / min and 50° C. for 12 hours to obtain the first mixture. Then put the first mixture in a vacuum drying oven at 90°C, and dry the first mixture to a constant weight under the condition of a vacuum of -0.04 to -0.06MPa, take it out and grind it until it passes through a 100-mesh sieve to obtain a molten ice aggregate.

[0080](2) Add 10 g of silane / siloxane concentrate (Z-6689 produced by Dow Corning) to 100 g of ethanol to obtain an organic solution of the hydrophobic agent. Then add 200 g of the ice-melting aggregate obtained in the above step (1), stir evenly with a disperser, and leave it open at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com