Preparation method of release agent emulsion for aluminum foil tape

A technology of aluminum foil tape and release agent, which is applied in the direction of adhesive, film/sheet adhesive, coating, etc. The use effect of the formulation is reduced, and the effect of increasing the use cycle and use effect, simple and pollution-free raw materials, and good stability can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

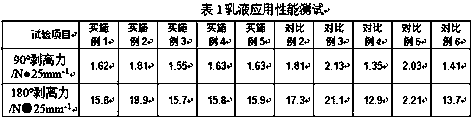

Examples

Embodiment 1

[0021] Embodiment 1 is the best embodiment of the present application, and the present invention will be further explained below in conjunction with the embodiments.

[0022] The oxidized polyethylene wax used in the following examples is OPE-4 produced by Linzi Qiquan Industry and Trade Co., Ltd. in Zibo City; the paraffin wax used is the fully refined paraffin wax No. 58 granular wax produced by Sinopec; the rosin used is Shandong Dengnuo Co., Ltd. The brand produced by the company is Pinus massoniana; the ammonia water used is 28% of analytical pure reagent; the compound emulsifier used is the brand OP-10 and OA-9 produced by Jiangsu Haian Petrochemical Factory.

[0023] Example 1

[0024] A method for preparing a release agent emulsion for aluminum foil tapes.

[0025] 1) Add 7g, 15g, and 7g of oxidized polyethylene wax, paraffin wax, and rosin, respectively, and heat up to 120°C to melt and keep stirring, stirring for 20 minutes until the color of the solution is uniform...

Embodiment 2

[0030] A method for preparing a release agent emulsion for aluminum foil tapes.

[0031] 1) Add 6g, 15g, and 6g of oxidized polyethylene wax, paraffin wax, and rosin, respectively, and heat up to 120°C to melt while stirring, and stir for 20 minutes until the color of the solution is uniform and there are no visible solids.

[0032] 2) Add 1g of 28% analytically pure ammonia water to the liquid obtained in the previous step and stir for 4 minutes.

[0033] 3) Add 3g of compound emulsifier and stir for 3 minutes.

[0034] 4) Add a total of 63.5g of 24°C deionized water at a rate of 7g / min while stirring at 120°C. After adding, stir for 25min until the solution is uniform and there is no stratification.

Embodiment 3

[0036] A method for preparing a release agent emulsion for aluminum foil tapes.

[0037] 1) Add 8g, 15g, and 8g of oxidized polyethylene wax, paraffin wax, and rosin, respectively, and heat up to 130°C to melt while stirring. Stir for 17 minutes until the color of the solution is uniform and there are no visible solids.

[0038] 2) Add 2g of 28% analytically pure ammonia water to the liquid obtained in the previous step and stir for 6 minutes.

[0039] 3) Add 5g of compound emulsifier and stir for 3 minutes.

[0040] 4) Add a total of 70g of 90°C deionized water at a rate of 22g / min while stirring at 130°C. After adding, stir for 15min until the solution is uniform and there is no stratification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com