A kind of preparation method of low flame spread coating

A low-flame-spreading and coating technology, used in fire-retardant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor corrosion resistance of low-flame-spreading cabin paint, improve market competitiveness, and reduce product costs. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

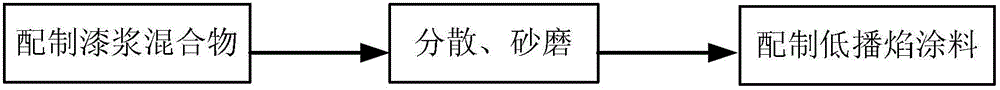

[0090] A preparation method for low flame spread coating, said method comprising the steps of:

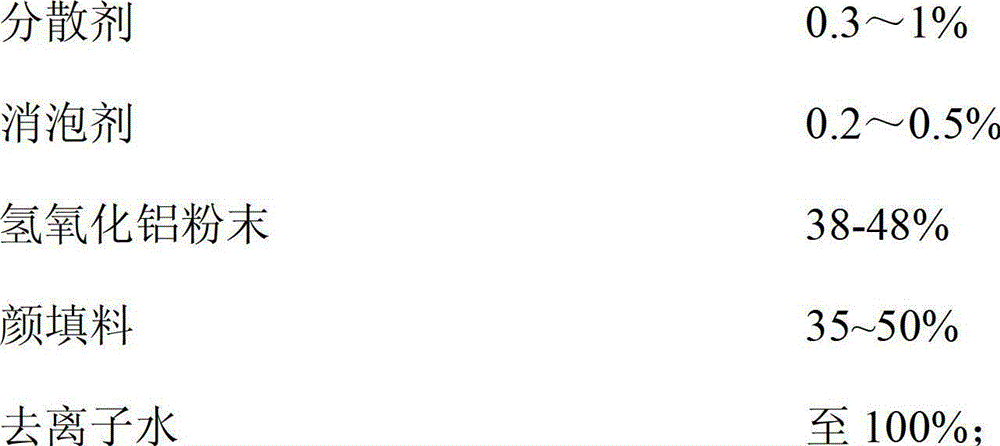

[0091] (1) Prepare the millbase mixture according to the following mass percentages:

[0092]

[0093] (2) Disperse the millbase mixture obtained in step (1) in a disperser at a low speed for 10 minutes, then disperse it at a high speed for 20 minutes, and then sand the millbase to ≤40 μm; the speed of the low-speed dispersion is 600 r / min, and the high-speed dispersion The speed is 1800r / min;

[0094] (3) Prepare the low flame spread coating according to the following mass percentage:

[0095]

[0096] The sum of the components of the low flame spread paint is 100%.

Embodiment 2

[0098] A preparation method for low flame spread coating, said method comprising the steps of:

[0099] (1) Prepare the millbase mixture according to the following mass percentages:

[0100]

[0101] (2) Disperse the millbase mixture obtained in step (1) in a disperser at a low speed for 8 minutes, then disperse it at a high speed for 40 minutes, and then sand the millbase to ≤38 μm; the rotational speed of the low-speed dispersion is 800 r / min, and the high-speed dispersion The speed is 1200r / min;

[0102] (3) Prepare the low flame spread coating according to the following mass percentage:

[0103]

[0104]

[0105] The sum of the components of the low flame spread paint is 100%.

Embodiment 3

[0107] A preparation method for low flame spread coating, said method comprising the steps of:

[0108] (1) Prepare the millbase mixture according to the following mass percentages:

[0109]

[0110] (2) Disperse the millbase mixture obtained in step (1) in a disperser at a low speed for 14 minutes, then disperse it at a high speed for 30 minutes, and then sand the millbase to ≤40 μm; the speed of the low-speed dispersion is 700 r / min, and the high-speed dispersion The speed is 1000r / min;

[0111] (3) Prepare the low flame spread coating according to the following mass percentage:

[0112]

[0113]

[0114] The sum of the components of the low flame spread paint is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com