Water-based epoxy anti-corrosive coating and preparation method thereof

A water-based epoxy and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, fire-retardant coatings, etc., to achieve the effect of low VOC and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

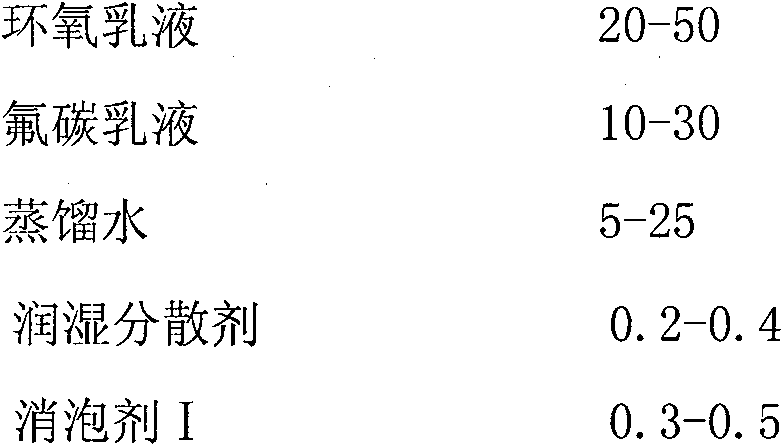

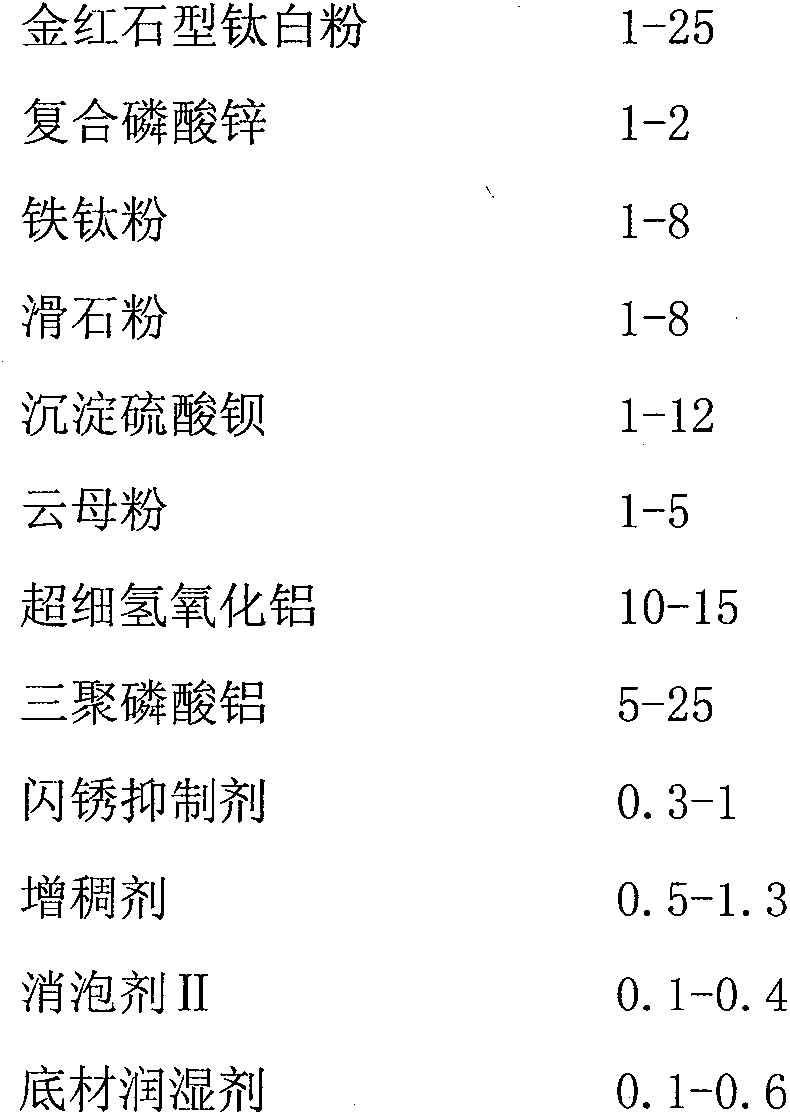

[0020] Example one: A component (parts by weight):

[0021]

[0022] B component:

[0023] Waterborne epoxy curing agent 100

[0024] A: B = 100:12, the effective period of construction is 6 hours.

[0025] Process preparation method:

[0026] Add water, additive wetting and dispersing agent, defoamer I, defoamer II, and flash rust inhibitor into the stock pot in sequence, stir evenly at low speed, then add pigments and fillers, disperse at high speed for more than 20 minutes, and the grinding fineness is ≤40 Micron (beware of demulsification during the grinding process), then add fluorocarbon emulsion and flash rust inhibitor, stir well, add thickener to thicken, stir well, measure viscosity, if viscosity ≥ 50s (coat -4 cups, 25°C) It is qualified. If the viscosity is ≤50s, add an appropriate amount of thickener to thicken until the viscosity is ≥50s, then add defoamer II to defoam, stir evenly and then slowly add substrate wetting agent. The control speed should not ex...

example 2

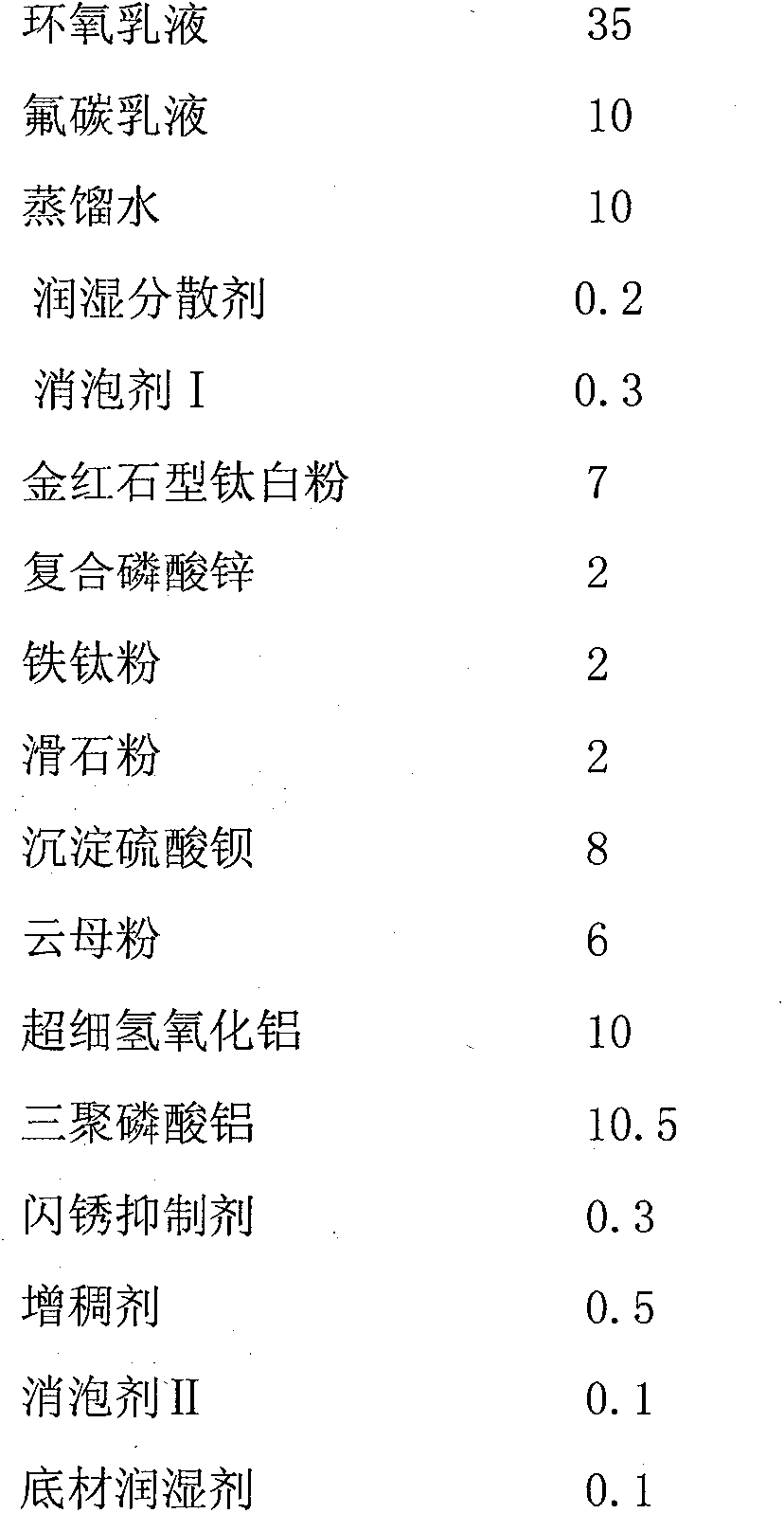

[0028] Example two: A component (parts by weight):

[0029]

[0030] B component:

[0031] Waterborne epoxy curing agent 100

[0032] A: B = 100:13, the effective period of construction is 6 hours.

[0033] Process preparation method:

[0034] Add water, additive wetting and dispersing agent, defoamer I, defoamer II, and flash rust inhibitor into the stock pot in sequence, stir evenly at low speed, then add pigments and fillers, disperse at high speed for more than 20 minutes, and the grinding fineness is ≤40 Micron (beware of demulsification during the grinding process), then add fluorocarbon emulsion and flash rust inhibitor, stir well, add thickener to thicken, stir well, measure viscosity, if viscosity ≥ 50s (coat -4 cups, 25°C) It is qualified. If the viscosity is ≤50s, add an appropriate amount of thickener to thicken until the viscosity is ≥50s, then add defoamer II to defoam, stir evenly and then slowly add substrate wetting agent. The control speed should not ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com